Method for preparing rutile type titanium dioxide by using ilmenite as raw material

A technology for preparing ilmenite and gold, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of high cost of three wastes treatment, large waste discharge, complicated process, etc., to reduce equipment costs, increase production, and improve extraction rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

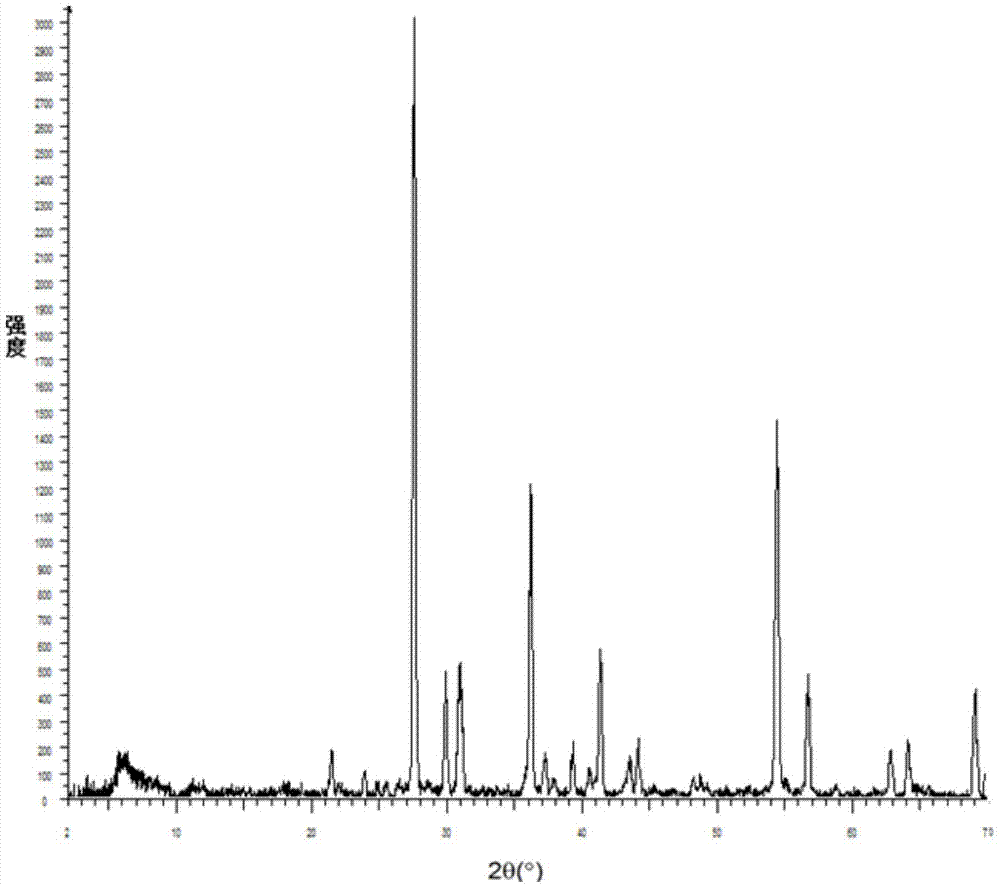

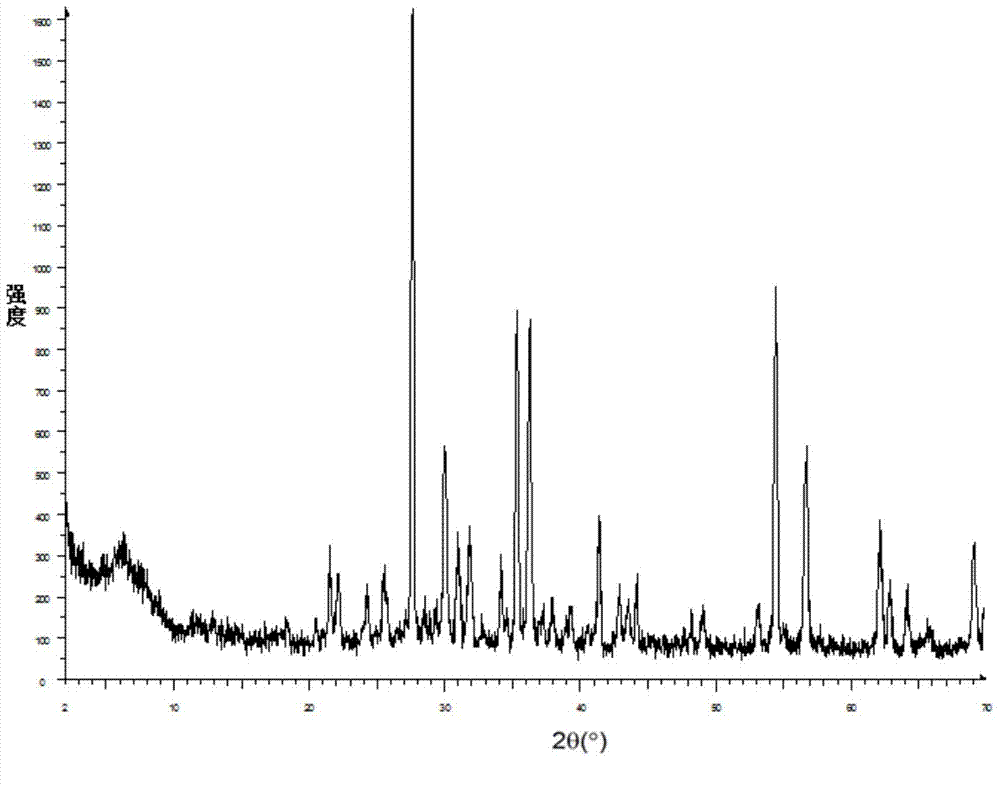

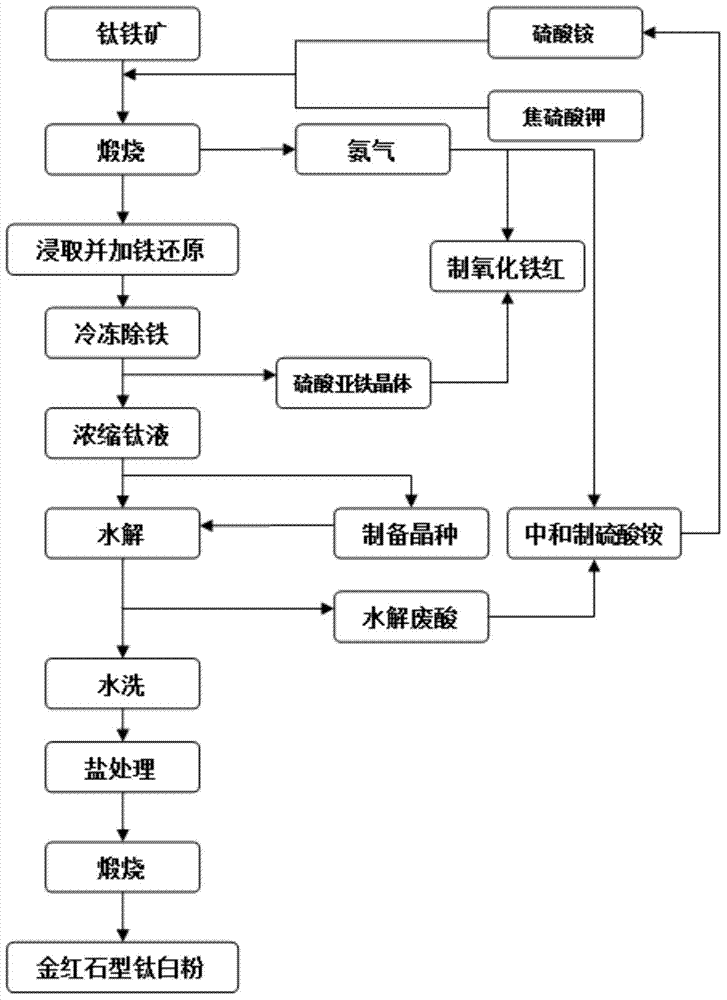

[0029] Such as figure 1 As shown, the ilmenite is ground and pulverized through a 300 mesh sieve, and the raw material with a mass of 75.00 g is pressed by m (ilmenite): m ((NH4) 2 SO 4 ):m(K 2 S 2 o 7 ) = 1:4:0.5, grind evenly, put it into the calciner, the reaction temperature is 360°C, and the holding time is 1h. Ammonia gas absorption is 18-20% ammonia water. Take the roasted ilmenite, put it into a three-necked flask after grinding, add 300ml of 30% dilute sulfuric acid for leaching, the leaching temperature is 65°C, and the leaching time is 10h, then add about 2.50g of iron filings to reduce for 4 hours. Under these conditions, the leaching rate of titanium reaches 96.82%. Concentrate the titanium solution, the volume ratio before and after concentration is 0.73, and then remove iron by freezing, the iron removal temperature is -15 °C, and the iron removal rate can reach 50.64% when the time is more than 15 hours. Ferrous sulfate is neutralized with ammonia water...

Embodiment 2

[0031] The ilmenite is crushed through a 350 mesh sieve, and the raw material with a quality of 75.05g is pressed by m (ilmenite): m ((NH4) 2 SO 4 ):m(K 2 S 2 o 7)=1:5:0.5 calcined. The calcination temperature is 400° C., the holding time is 30 minutes, and the ammonia gas absorption is 18-20% ammonia water. Add 300ml, 20% dilute sulfuric acid for leaching, the leaching temperature is 60°C, the leaching time is 8h, and then add about 2.50g of iron filings for reduction for 4 hours. Under these conditions, the leaching rate of titanium reaches 96.82%. Concentrate the titanium solution to 0.5 times the original volume, then the iron can be removed by freezing. The iron removal temperature is -16°C, and the iron removal rate can reach 50.64% when the time is more than 15 hours. The titanium solution is concentrated at about 65°C, and the concentration ratio is 0.55. 7% by weight of the concentrated titanium liquid is used as the raw material for producing rutile-type seed ...

Embodiment 3

[0033] When calcining, the raw material is m (ilmenite): m ((NH4) 2 SO 4 ):m(K 2 S 2 o 7 )=1:6:0.5, the total mineral mass is 75.00g, the reaction temperature is 450°C, the holding time is 1.5h, and the ammonia gas absorption is 18-20% ammonia water. Add 300ml, 30% dilute sulfuric acid for leaching, the leaching temperature is 70°C, the leaching time is 10h, and then add about 2.50g of iron filings for reduction for 4 hours. After suction filtration, the leaching solution is concentrated, with a concentration ratio of 0.7; then, iron removal is performed by freezing at a temperature of -18°C, and the iron removal rate can reach 46.23% when the time is more than 16 hours. After removing iron, concentrate the titanium liquid at about 65°C, and the concentration ratio is 0.6. 7% by weight of the concentrated titanium liquid is used as the raw material for producing rutile-type seed crystals, zinc oxide is added to the seed crystal raw material, the pH value is adjusted at 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com