Rotary type self-glazing elbow pipe glazing device and glazing method thereof

A self-glazing and rotary technology, which is applied in the field of ceramic toilet elbow glazing devices, can solve the problems of cumbersome adjustment, low efficiency, and high price, and achieve the effects of improving product quality, increasing production efficiency, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

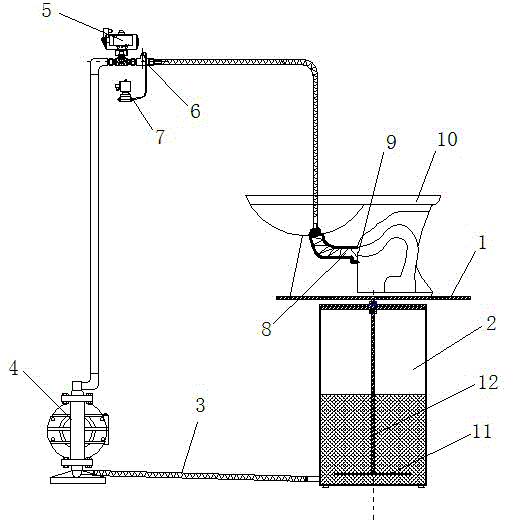

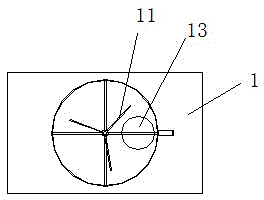

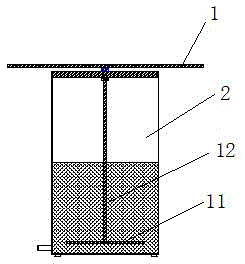

[0030] The present invention is described in detail below with reference to accompanying drawing and embodiment:

[0031] attached Figures 1 to 3 It can be seen that, a rotary self-glazing elbow glazing method, the glazing toilet green body 10 is placed on the glazing workbench 1, and the water wiping operation is carried out;

[0032] Including the following steps:

[0033] A. Align the nozzle 8 of the glaze slurry pipe with the inlet 9 of the waterway;

[0034] B, start diaphragm pump 4; Start air compressor 7;

[0035] C. Open the pneumatic solenoid valve 5; the opening time of the pneumatic solenoid valve 5 is set according to the PLC program to determine the supply time;

[0036] D, close the pneumatic solenoid valve 5;

[0037] E. Open the compressed air solenoid valve 6;

[0038] F. Under the blowing of air pressure, the glaze slurry flows through the elbow pipe of the toilet, and the excess glaze slurry flows into the glaze storage tank 2 for recycling;

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com