Method for treating seed precipitated aluminum hydroxide size

A technology of aluminum hydroxide and aluminum oxide, applied in the direction of aluminum oxide/aluminum hydroxide, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of reducing the solid content and viscosity of flat slurry, the effect is not ideal, and the reduction of aluminum hydroxide Slurry feed solid content and slurry viscosity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

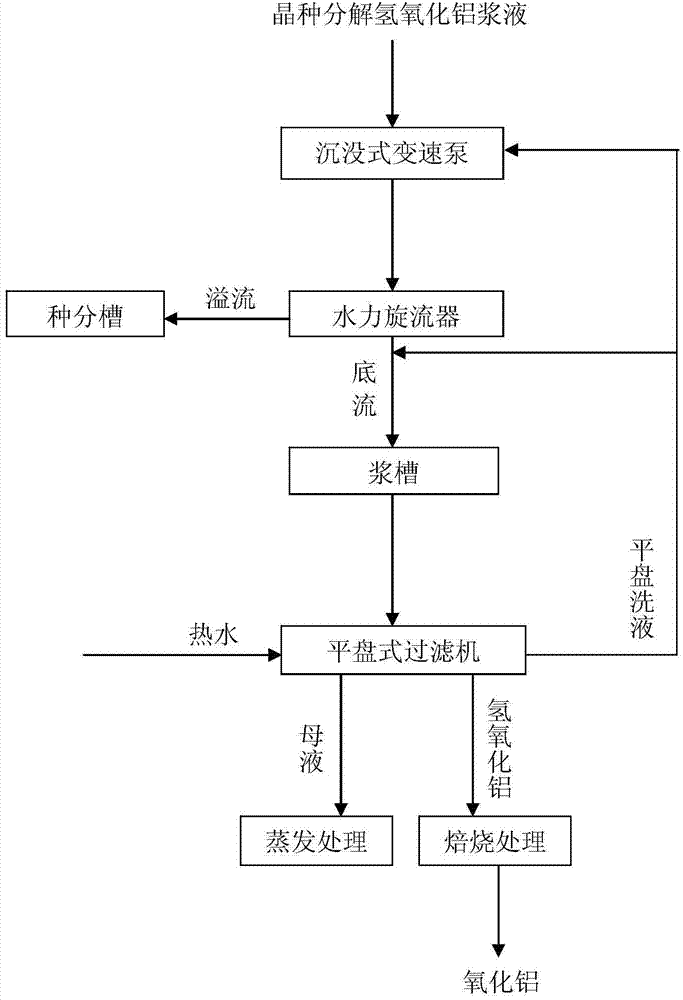

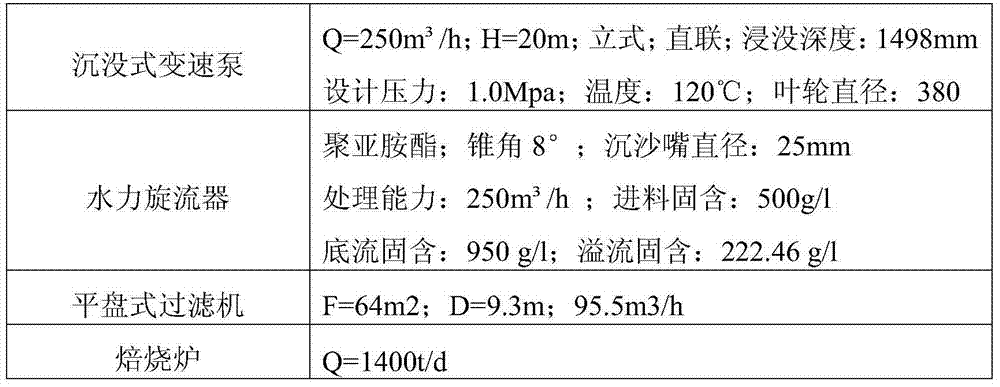

[0032] As shown in Figure 1, during the production of alumina by the Bayer process, the submerged variable speed pump is used to pump the seed decomposed aluminum hydroxide slurry into the hydrocyclone; the cyclone is used to classify the seed decomposed aluminum hydroxide slurry In order to obtain overflow aluminum hydroxide slurry and underflow aluminum hydroxide slurry; pass the underflow aluminum hydroxide slurry into the slurry tank for temporary storage; pass the underflow aluminum hydroxide slurry in the slurry tank into a flat disc filter for Filtrate to obtain the mother liquor, and wash the filtered aluminum hydroxide with hot water at a temperature of 93 degrees Celsius to obtain flat washing liquid and aluminum hydroxide; send the aluminum hydroxide into a gaseous suspension type roaster for roasting, so that Alumina is obtained; among them, the flat plate washing liquid (alkalinity is about 90g / L) is returned to the submerged variable speed pump inlet and the under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com