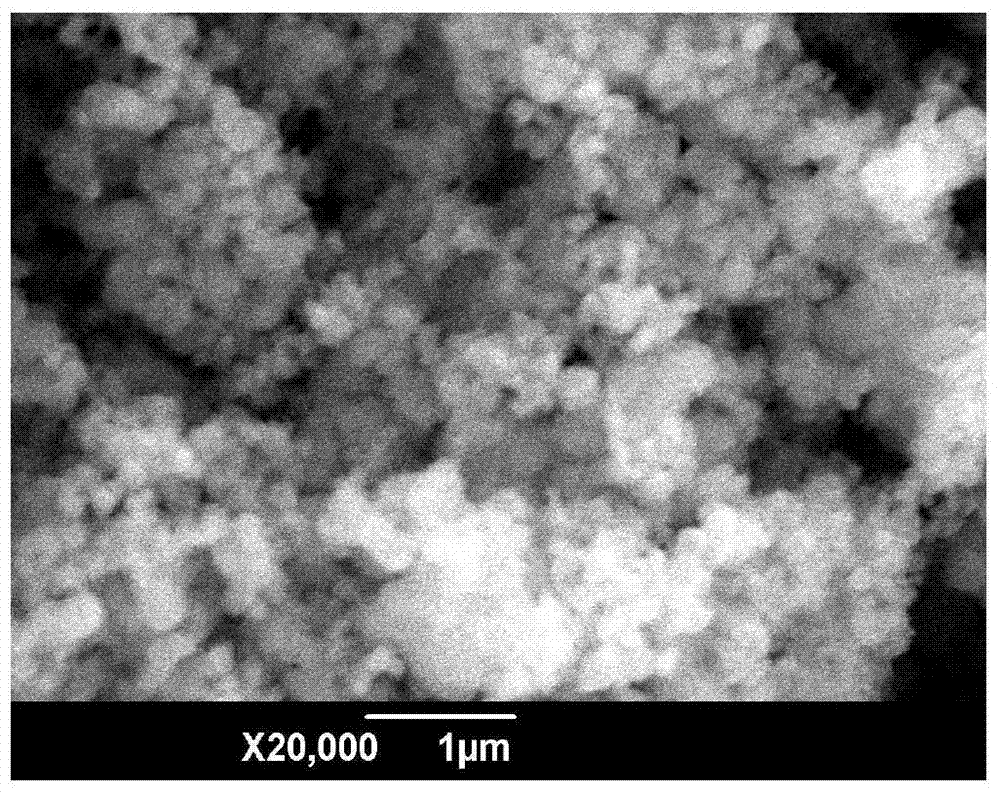

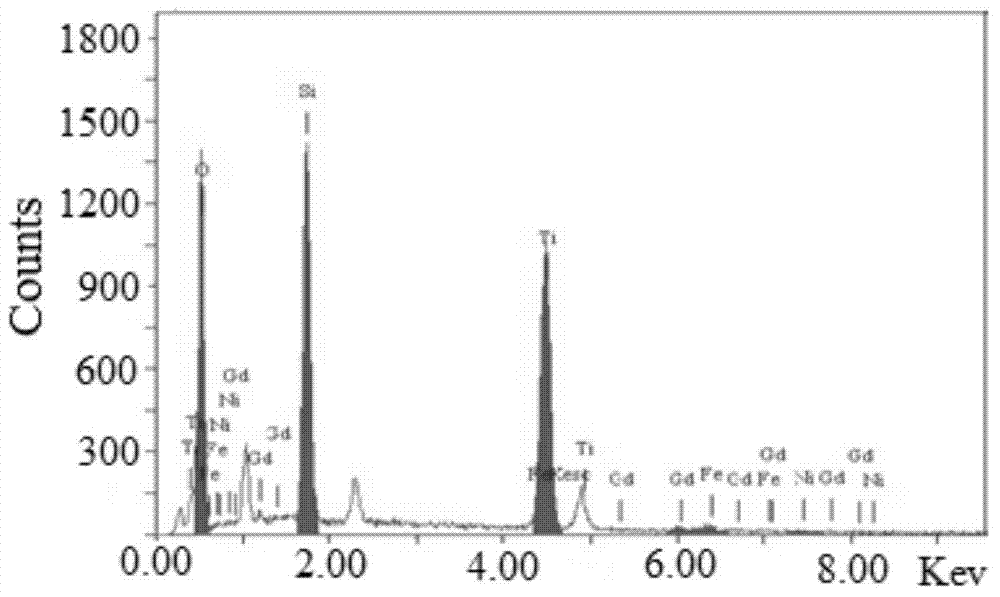

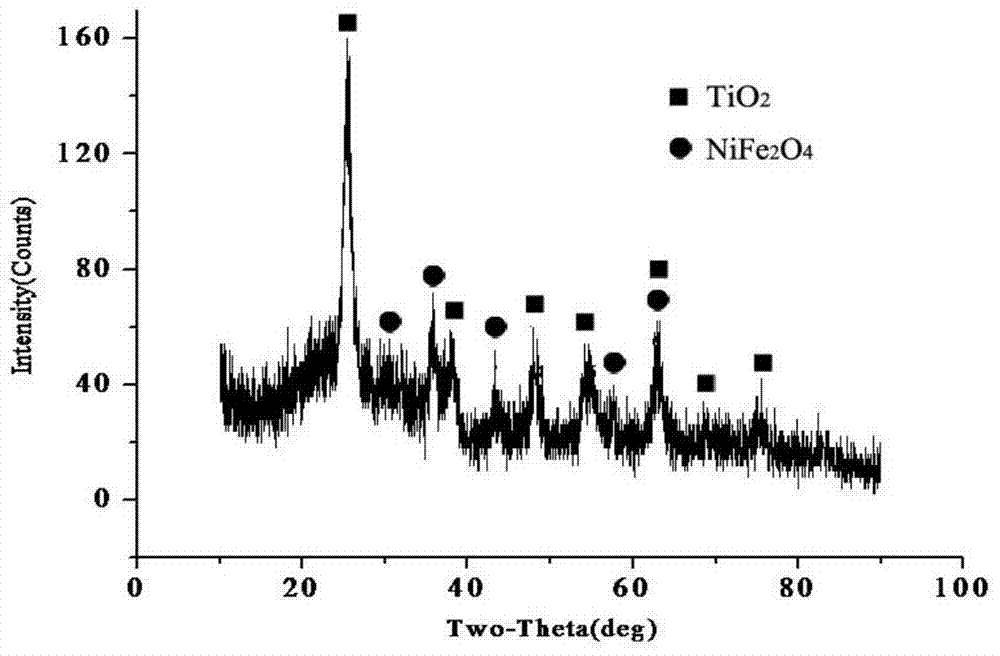

Preparation method of Gd-TiO2-SiO2-NiFe2O4 composite magnetic material

A technology of gd-tio2-sio2-nife2o4 and composite magnetic materials, which is applied in illumination water/sewage treatment, energy and wastewater treatment, etc., can solve the problems of poor stability and easy aggregation of suspended phase catalysts, and achieves overcoming poor stability and simple process. , Overcome the effect of easy aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment includes the following steps:

[0030] (1) Gd-doped TiO 2 preparation of

[0031] Use 10mL n-tetrabutyl titanate as TiO 2 Use 10mL of absolute ethanol as a solvent to obtain the A solution after mixing thoroughly. At the same time, another 5 mL of 0.1 mol / L gadolinium nitrate aqueous solution was taken as solution B. The obtained B solution was added to the A solution, and concentrated hydrochloric acid was added to adjust the pH to 7, and a sol was obtained after stirring. The sol was dried at 80 °C and then calcined at 500 °C for 4 h to prepare Gd-doped TiO 2 .

[0032] (2)NiFe 2 o 4 Powder preparation

[0033]At a reaction temperature of 70°C, mix 10 mL of 0.15 mol / L nickel nitrate and 10 mL of 0.2 mol / L ferric nitrate, adjust the pH of the system to 12 with NaOH, filter the resulting precipitate, and wash it several times with distilled water to obtain a filter cake Dry at 90°C, and calcined at 600°C for 5 hours after fully grinding to obtai...

Embodiment 2

[0043] This embodiment includes the following steps:

[0044] (1) Gd-doped TiO 2 preparation of

[0045] Use 10mL n-tetrabutyl titanate as TiO 2 Use 10mL of absolute ethanol as a solvent to obtain the A solution after mixing thoroughly. At the same time, another 2 mL of 0.1 mol / L gadolinium nitrate aqueous solution was taken as solution B. Add the obtained B solution to A solution, add concentrated hydrochloric acid to adjust the pH to 6, and obtain a sol after stirring. The sol was dried at 80 °C and then calcined at 500 °C for 4 h to prepare Gd-doped TiO 2 .

[0046] (2)NiFe 2 o 4 Powder preparation

[0047] At a reaction temperature of 60°C, mix 10 mL of 0.15 mol / L nickel nitrate and 10 mL of 0.2 mol / L ferric nitrate, adjust the pH of the system to 11 with NaOH, filter the resulting precipitate, and wash it several times with distilled water to obtain a filter cake Dry at 90°C, and calcined at 600°C for 5 hours after fully grinding to obtain NiFe 2 o 4 Powder.

...

Embodiment 3

[0056] This embodiment includes the following steps:

[0057] (1) Gd-doped TiO 2 preparation of

[0058] Use 10mL n-tetrabutyl titanate as TiO 2 Use 10mL of absolute ethanol as a solvent to obtain the A solution after mixing thoroughly. At the same time, another 8 mL of 0.1 mol / L gadolinium nitrate aqueous solution was taken as solution B. The obtained B solution was added to the A solution, and concentrated hydrochloric acid was added to adjust the pH to 7, and a sol was obtained after stirring. The sol was dried at 80 °C and then calcined at 500 °C for 4 h to prepare Gd-doped TiO 2 .

[0059] (2)NiFe 2 o 4 Powder preparation

[0060]At a reaction temperature of 60°C, mix 20 mL of 0.15 mol / L nickel nitrate and 20 mL of 0.2 mol / L ferric nitrate, adjust the pH of the system to 12 with NaOH, filter the resulting precipitate, and wash it several times with distilled water to obtain a filter cake Dry at 90°C, and calcined at 600°C for 5 hours after fully grinding to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com