Magnetic cucurbit urils/grapheme oxide composite material and preparation method thereof

A magnetic composite material and graphene technology, applied in the field of materials, can solve the problems of low yield, cumbersome preparation steps, high cost, etc., and achieve the effect of good dispersion, good application prospects, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

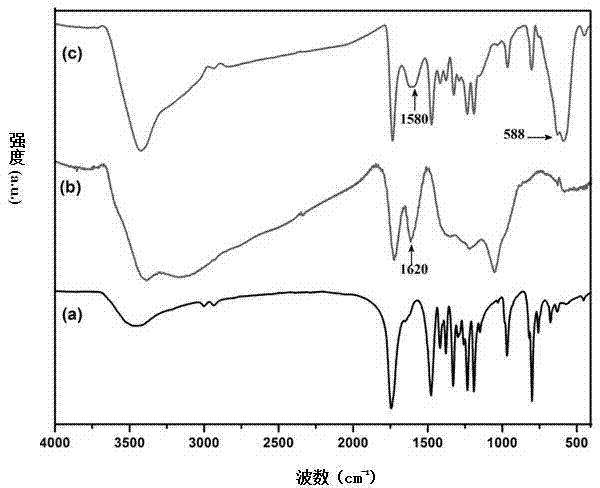

[0047]Graphene oxide was prepared by the Hummers method: under ice bath, in a three-necked flask, 3 g of flake graphite was mixed with 90 mL of concentrated sulfuric acid, then 9 g of potassium permanganate was added in batches (10 times), and stirred After 1 h, raise the temperature to 35 °C and keep it for 2 h, then add 250 mL of deionized water to the system, raise the temperature to 95 °C, keep it for 30 min, add 10 mL of hydrogen peroxide, centrifuge, and wash the solid with 5% hydrochloric acid for 5 times , and finally washed once with ethanol, and the product was dried in an oven at 50 °C for later use.

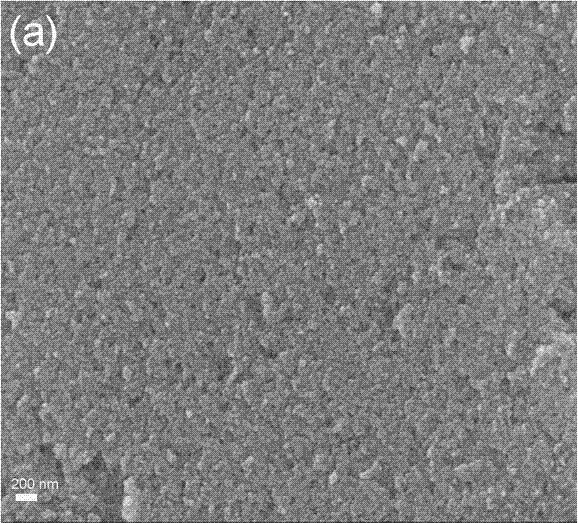

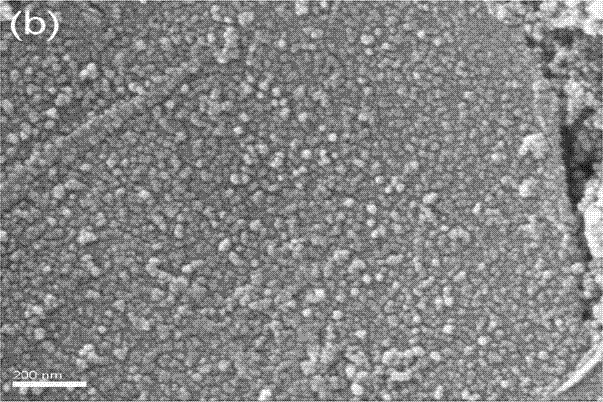

[0048] 0.25 g of graphene oxide prepared by the Hummers method was placed in 200 mL of deionized water and ultrasonicated for 3 h until it was completely dispersed and exfoliated to obtain the first solution. Transfer the first solution to a 500 mL three-necked bottle, then weigh 0.25 g of six-membered cucurbit rings into the three-necked bottle, stir under a nitrogen...

Embodiment 2

[0051] 0.25 g of graphene oxide prepared by the Hummers method was placed in 200 mL of deionized water and ultrasonicated for 3 h until it was completely dispersed and exfoliated to obtain the first solution. Transfer the first solution to a 500 mL three-necked bottle, then weigh 0.15 g of six-membered cucurbitan rings into the three-necked bottle, stir under a nitrogen gas atmosphere, heat the system to 40 °C, and keep it for 0.5 h to obtain the second solution . Then, 0.768 g of ferrous sulfate heptahydrate and 1.488 g of ferric chloride hexahydrate were added to the second solution, and the system was heated to 85 °C. After the melon ring was dissolved, it was kept for 1 h to obtain the third solution. Finally, 15 mL of 30% ammonia solution was added to the third solution, the reaction was continued for 1 h, and the precipitate was collected by filtration. After the precipitate is washed and dried, the graphene oxide / cucurbit ring magnetic composite material is obtained. ...

Embodiment 3

[0054] 0.25 g of graphene oxide prepared by the Hummers method was placed in 200 mL of deionized water and ultrasonicated for 3 h until it was completely dispersed and exfoliated to obtain the first solution. Transfer the first solution to a 500 mL three-necked bottle, then weigh 0.4 g of six-membered cucurbit rings into the three-necked bottle, stir under a nitrogen gas atmosphere, heat the system to 40 °C, and keep it for 0.5 h to obtain the second solution . Then, 0.768 g of ferrous sulfate heptahydrate and 1.488 g of ferric chloride hexahydrate were added to the second solution, and the system was heated to 85 °C. After the melon ring was dissolved, it was kept for 1 h to obtain the third solution. Finally, 15 mL of 30% ammonia solution was added to the third solution, the reaction was continued for 1 h, and the precipitate was collected. After the precipitate is washed and dried, the graphene oxide / cucurbit ring magnetic composite material is obtained.

[0055] Through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Saturation magnetic moment | aaaaa | aaaaa |

| Adsorption temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com