Method for drying yellow peach through pulse pneumatic-puffing and product thereof

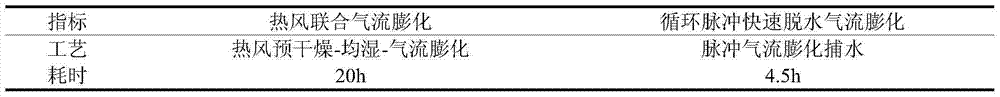

An air puffing and yellow peach technology, applied in the field of fruit and vegetable drying processing, can solve the problems of large volume of air puffing equipment, limited extraction efficiency, increased floor space, etc., and achieve rapid and healthy development of the industry, energy saving and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

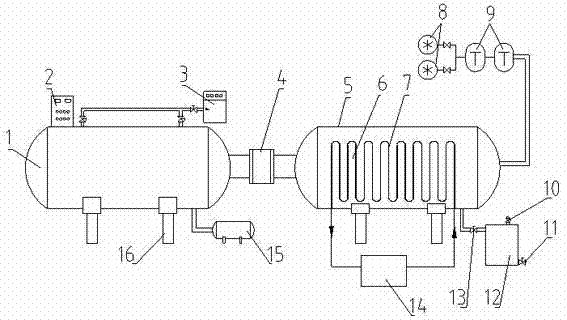

Method used

Image

Examples

Embodiment 1

[0074] Select canned peach 14 (purchased in the market) fresh yellow peach variety as raw material, select nine-ripe fruit, clean the surface of the yellow peach fruit with clear water, peel, remove the core, cut the yellow peach into a width of 2 cm at the bottom, and a width of 2 cm at the top. 1cm, length 3cm, height 2cm trapezoidal block. Put the diced yellow peaches into a sugar solution with a concentration of 10% preheated to 95°C, cook for 5 minutes, soak at 40°C for 75 minutes, and freeze at -18°C for 12 hours after dipping and cooling.

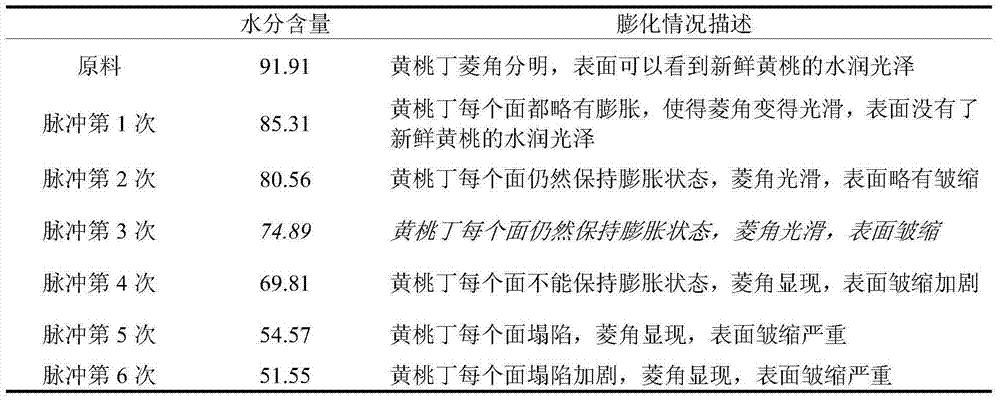

[0075] Thaw 3 kg of frozen diced yellow peaches at room temperature. After thawing completely, drain the surface moisture of the diced yellow peaches and place them evenly on the material tray. Put the material tray with diced yellow peaches into the 300L expansion tank 1, heat up to 100°C, stagnate for 15 minutes and keep warm at 100°C, and make the pressure difference between the expansion tank 1 and the 600L vacuum tank 5 be 150kP...

Embodiment 2

[0081] Choose Jintong No. 8 (purchased in the market) fresh yellow peach variety as raw material, select 3 kg of nine-ripe fruit, clean the surface of the peach fruit with clear water, peel, remove the core, cut the yellow peach into a 2cm wide section, and A trapezoidal block with a width of 1cm, a length of 3cm, and a height of 2cm. Put the diced yellow peaches into a sugar solution with a concentration of 8% and preheated to 98°C, cook for 3 minutes, soak at 50°C for 60 minutes, and freeze at -18°C for 15 hours after dipping and cooling.

[0082] Thaw 3 kg of frozen diced yellow peaches at room temperature. After thawing completely, drain the surface moisture of the diced yellow peaches and place them evenly on the material tray. Put the material tray containing 3kg of yellow peach cubes into a 300L expansion tank, heat up to 105°C, stagnate for 10min and keep warm at 105°C, the pressure difference between the expansion tank and the 600L vacuum tank is 120kPa, and turn on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com