Photovoltaic cell module and manufacturing method thereof

A photovoltaic cell and manufacturing method technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as affecting the appearance and reliability of photovoltaic modules, high long-term stability, and breaking welding joints, so as to improve long-term stability, The effect of improving performance and reducing corrosion requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

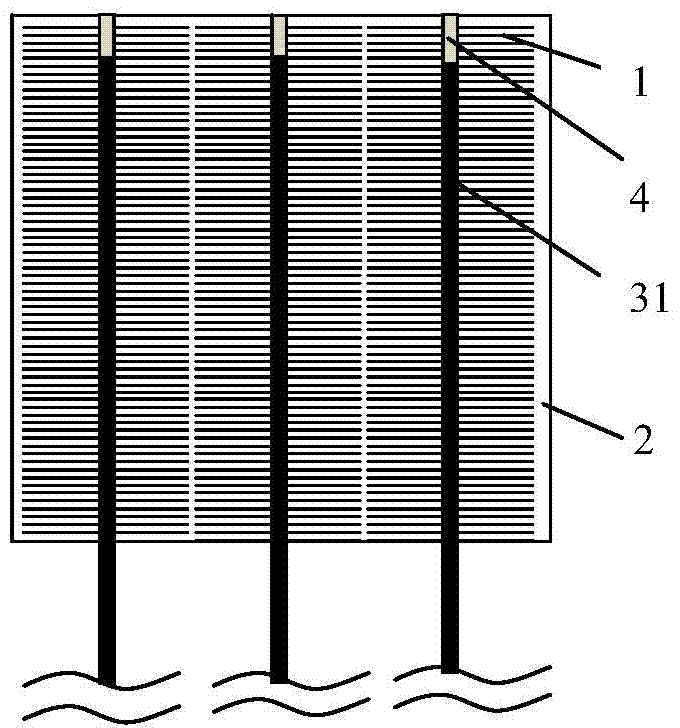

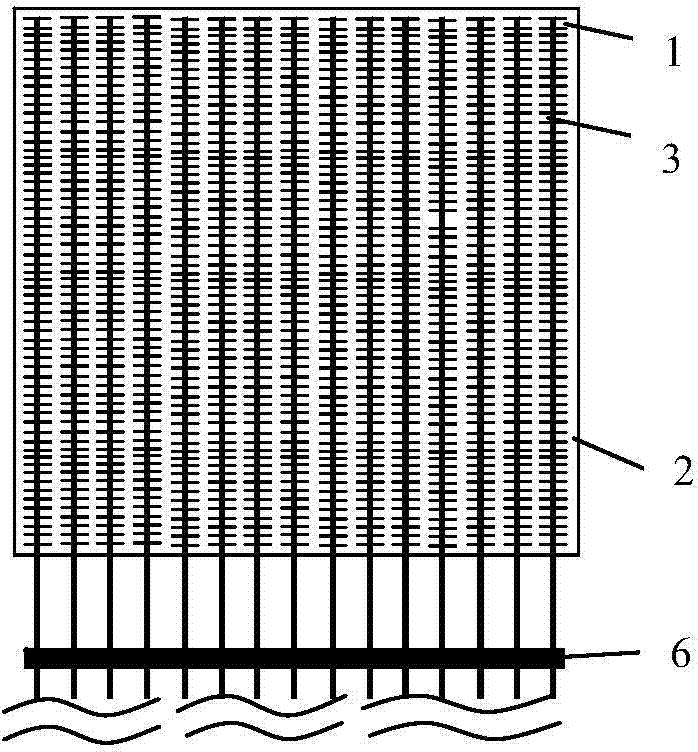

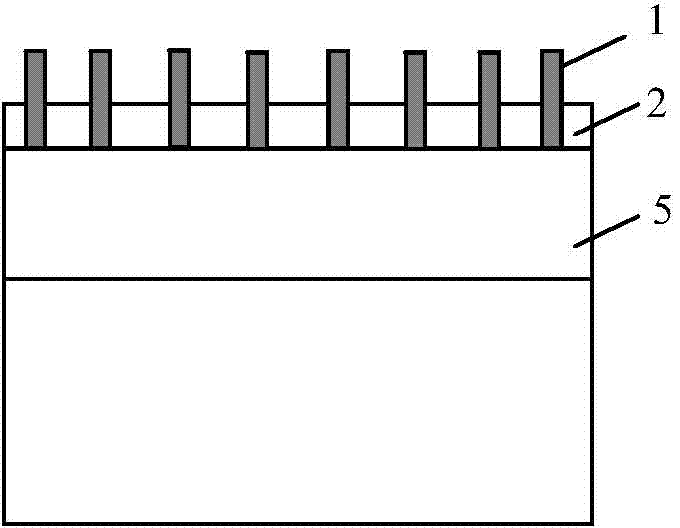

[0046] Embodiment 1: For the embodiment of a conventional P-type battery, Cu interconnection wires and heat-curable Cu conductive paste are used.

[0047] 15 thin Cu wires are selected as interconnection wires 31 between the battery slices, the cross section of the thin Cu wires is square, and the side length of the square is 0.3 mm. The surface of the thin Cu wire is not coated with Sn layer.

[0048] Coating heat curing type Cu conductive paste on the surface of thin Cu wire. The solid content of heat-curable Cu conductive paste is 60-90%, and the density is 3.5-6g / cm 3 . Coating thickness is about 5um.

[0049] The fine Cu wire is straightened by a traction mechanism, and the heat-curable Cu conductive paste is coated on the fine Cu wire by a roller brushing method. The area where the heat-curable Cu conductive paste is coated on the fine Cu wire is limited to the area that needs to be connected to the battery sheet, and the heat-curable Cu conductive paste is not coate...

Embodiment 2

[0054] Embodiment 2: For the embodiment of thin-film silicon / crystalline silicon heterojunction cells, Cu interconnection wires and heat-curable Cu conductive paste are used.

[0055] 15 thin Cu wires are selected as interconnection wires 31 between the battery slices, the cross section of the thin Cu wires is square, and the side length of the square is 0.3 mm. The surface of the thin Cu wire is not coated with Sn layer.

[0056] Coating heat curing type Cu conductive paste on the surface of thin Cu wire. The solid content of heat-curable Cu conductive paste is 60-90%, and the density is 3.5-6g / cm 3 . Coating thickness is about 5um.

[0057] The fine Cu wire is straightened by a traction mechanism, and the heat-curable Cu conductive paste is coated on the fine Cu wire by a roller brushing method. The area where the heat-curable Cu conductive paste is coated on the fine Cu wire is limited to the area that needs to be connected to the battery sheet, and the heat-curable Cu ...

Embodiment 3

[0062] Embodiment 3: For the embodiment of thin-film silicon / crystalline silicon heterojunction cells, Cu interconnection wires and heat-curable Ag conductive paste are used. Same as the other descriptions of Example 2, only the low-temperature-curing heat-curable Cu conductive paste was replaced by the low-temperature-curable heat-curable Ag conductive paste commonly used in the photovoltaic cell industry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com