Combustion adjustment method of a supercritical boiler mixed with coke oven gas

A technology for supercritical boilers and coke oven gas, which is applied to combustion methods, combustion control, combustion equipment, etc., and can solve the problems of overheating and explosion of pipes on the heating surface, increasing the operating cost of denitrification devices, and uneven heating of pipe walls. , to achieve the effect of reducing smoke temperature deviation, suppressing residual rotation, and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

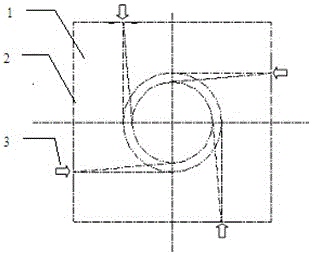

[0018] Example: such as Figure 1~4 As shown, a combustion adjustment method of a supercritical boiler mixed with coke oven gas includes a supercritical boiler mixed with coke oven gas, the boiler includes a boiler furnace 1, a water wall 2, a secondary damper 3, and Damper 4, gas gun 5, and secondary damper 3 are arranged on four water-cooled wall walls in the furnace of the boiler, including eight floors arranged vertically downward in sequence. The burnout damper 4 is arranged at the four corners of the water-cooled wall above the secondary damper in the furnace. Above, the gas gun 5 includes four layers, which are respectively arranged on the second layer (the AB layer in the figure), the third layer (the BC layer in the figure), and the fifth layer (the DE layer in the figure) of the secondary damper 3 from bottom to top. and the sixth floor (the EF floor in the figure), the combustion adjustment method includes: the second air door 3 of the eighth floor adopts the non-li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com