Gas constant-flow output feedforward control apparatus and gas constant-flow output feedforward control method

A feedforward control, constant flow technology, applied in the field of feedforward control systems, can solve problems such as large jitter in the collection volume, the upstream pressure cannot be kept constant, and the output value of the actuator is affected, so as to achieve a simple and easy control scheme and avoid measurement Effect of value perturbation or control response lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

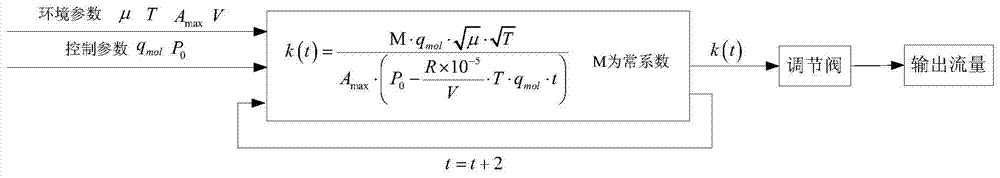

[0023] Write the PLC control program in advance according to the relationship between the pressure drop rate of the gas storage tank and the gas flow rate, and set the input parameters. During the pressure drop of the gas storage tank, the opening of the regulating valve is controlled by the PLC to increase continuously, and a gas storage tank is constructed. The feedforward control method of constant flow output is used for the constant flow supply of large flow gas in gas-liquid mixed reaction. The scheme includes PLC controller, pressure sensor, regulating valve, gas storage tank and pipeline, and stop valve.

[0024] The operation station is used for parameter setting and real-time monitoring. The PLC controller is used to calculate the valve opening and drive the regulating valve. The gas storage tank has stored a certain number of moles o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com