A kind of zirconium phosphate type high temperature nickel red ceramic pigment and preparation method thereof

A technology of ceramic pigment and zirconium phosphate type, which is applied in the field of zirconium phosphate type high temperature nickel red ceramic pigment and its preparation, can solve the problems of unstable color, unstable crystal structure, unstable performance, etc. The effect of bright colors and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh raw material 15g, according to diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 )55.8%, zirconia (ZrO 2 )44.2%, plus black nickel oxide (Ni 2 o 3 ) at a ratio of 2%, add water, stir evenly, and then dry to obtain the mixture; grind and sieve the obtained mixture, and place it in a resistance furnace for calcination, the calcination temperature is 1370°C, and the holding time is 75min; the calcined pigment is pulverized, ground and Washing, drying, crushing and drying to obtain a high-temperature nickel red ceramic pigment with a service temperature range of ≤1370°C.

Embodiment 2

[0023] Weigh raw material 15g, according to diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 )58.8%, zirconia (ZrO 2 )41.2%, plus black nickel oxide (Ni 2 o 3 ) at a ratio of 4%, add water and stir evenly, then dry to obtain the mixture; grind and sieve the obtained mixture, and place it in a resistance furnace for calcination, the calcination temperature is 1400°C, and the holding time is 60min; the calcined color material is crushed, ground and washed , after drying, pulverize and dry to obtain a high-temperature nickel red ceramic pigment with a service temperature range of ≤1400°C. The XRD test results are as follows: figure 1 shown.

Embodiment 3

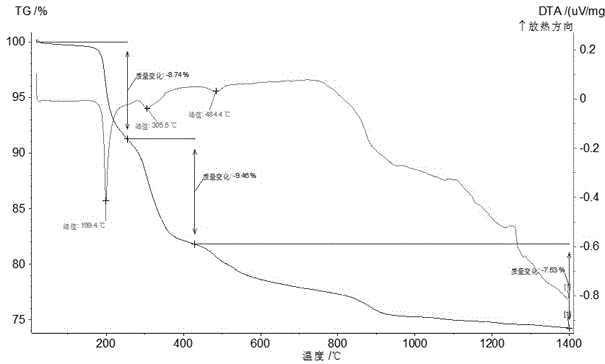

[0025] Weigh raw material 15g, according to diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 )58.8%, zirconia (ZrO 2 )41.2%, plus black nickel oxide (Ni 2 o 3 ) 6% of the ratio, add water and stir evenly, then dry to obtain the mixture; grind and sieve the obtained mixture, and place it in a resistance furnace for calcination, the calcination temperature is 1400°C, and the holding time is 60min; the calcined color material is pulverized, ground and washed , after drying, pulverize and dry to obtain a high-temperature nickel red ceramic pigment with a service temperature range of ≤1400°C, and its TG-DTA test curve is as follows figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com