Lead-free ferroelectric upconversion fluorescent ceramic material as well as preparation method and application thereof

A fluorescent ceramic and ferroelectric technology, applied in the field of up-conversion luminescent materials, can solve the problems of complex preparation process, fluoride toxicity, low chemical and physical stability, and achieve the effect of expanding the application range and improving leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

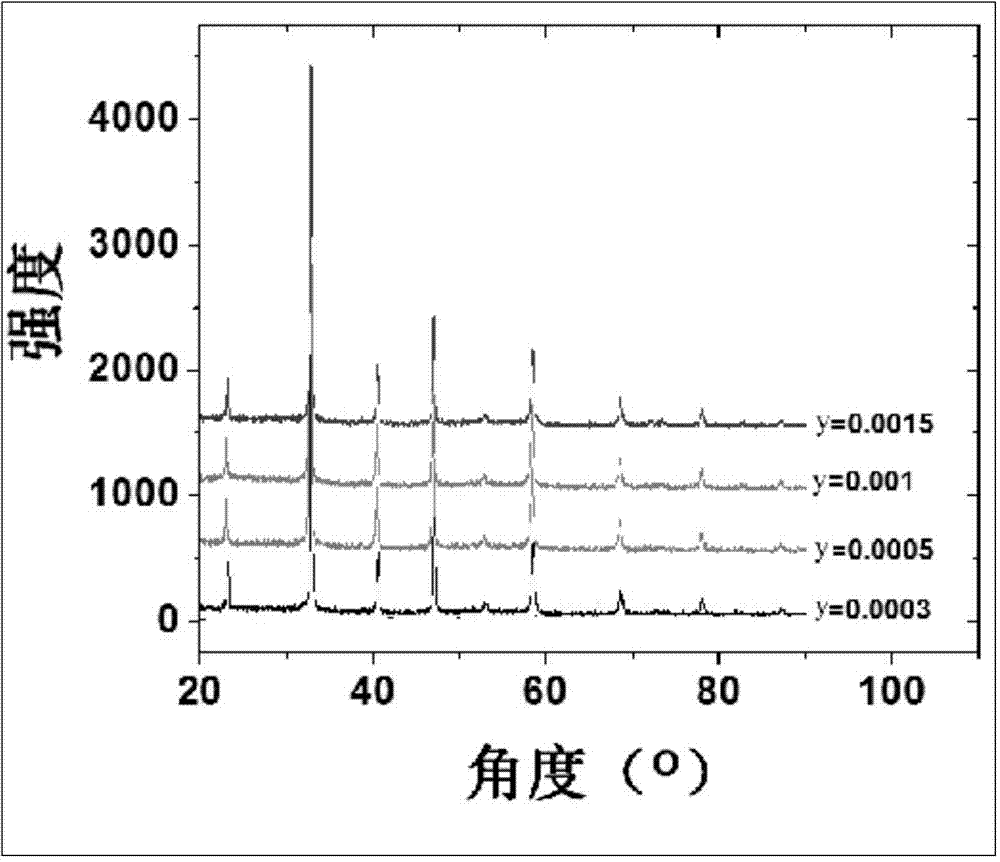

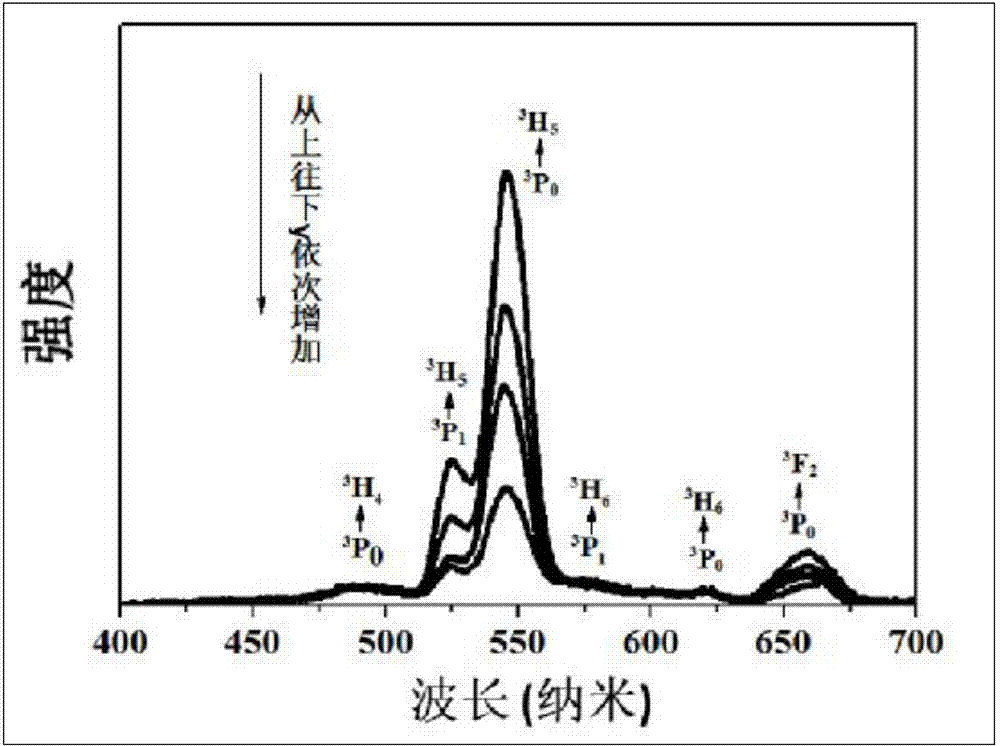

[0027] Embodiment 1, adopts the Na of purity 99.8% 2 CO 3 , 99.9% Bi 2 o 3 ,99.8% TiO 2 , 99.9% of Pr 2 o 3 and 99.9% Yb 2 o 3 As raw material, according to the chemical formula Bi 0.48-y Na 0.5 Yb 0.02 PR y TiO 3 (y=0.0003, 0.0005, 0.001, 0.0015) are weighed separately, put into a ball mill tank and mixed for ball milling, ball milling conditions: the volume ratio of raw materials, agate ball volume, and ball milling medium anhydrous ethanol is approximately equal to 1:1 : 1.5, it was ball milled for 12 hours, and the raw material after ball milling was put into an oven and baked at 80° C. for 4 hours. Afterwards, use a tablet machine to press the dried raw materials into raw material embryos with a diameter of 40 mm, and then put the pressed embryos into a KBF1400 box furnace for pre-calcination. The pre-calcination condition is 850 ° C for 2 hours. , and then crush the pre-fired block sample, grind it into powder, sieve it, ball mill it for 12 hours, and put it...

Embodiment 2

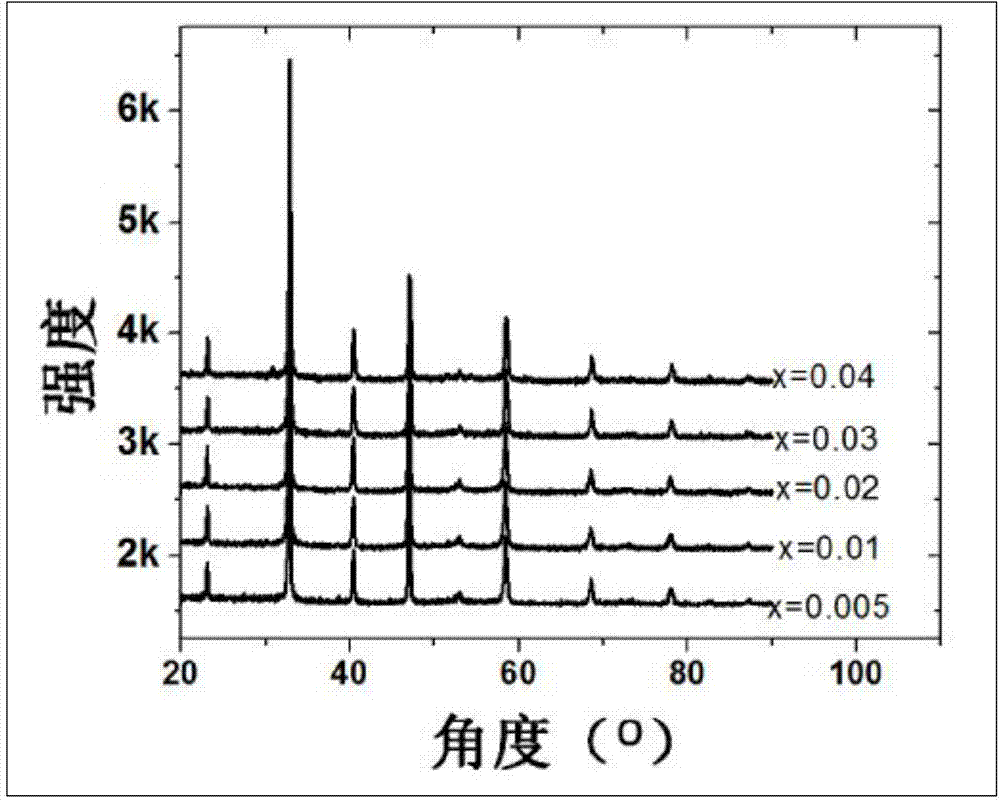

[0030] Embodiment 2, adopt the Na of purity 99.8% 2 CO 3 , 99.9% Bi 2 o 3 ,99.8% TiO 2 , 99.9% of Pr 2 o 3 and 99.9% Yb 2 o 3 As the raw material according to the chemical formula Bi 0.4997-x Na 0.5 wxya 0.0003 TiO 3 (x=0.005, 0.01, 0.02, 0.03, 0.04) weighing ratios were weighed respectively. The steps similar to Example 1 prepared 5 groups of Bi with different components respectively 0.4997-x Na 0.5 wxya 0.0003 TiO 3 (x=0.005,0.01,0.02,0.03,0.04) lead-free ferroelectric up-conversion fluorescent ceramics.

[0031] image 3 is the X-ray diffraction pattern of the prepared ceramics, from image 3 It can be seen that, except for x=0.04, the ceramics of the other four components have a pure perovskite structure.

[0032] Figure 4 It is the visible fluorescence spectrum emitted by five kinds of ceramics under the excitation of laser with a wavelength of 980nm. From the perspective of luminous intensity, when x exceeds 0.02, the green fluorescence intensity doe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com