RTM (resin transfer molding) molding method for carbon-fibre composite complex grid structure

A composite material and grid structure technology, applied in the field of molding, can solve the problems of complex molds, and achieve the effects of simplified metal molds, simple and convenient operation, and small compression ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

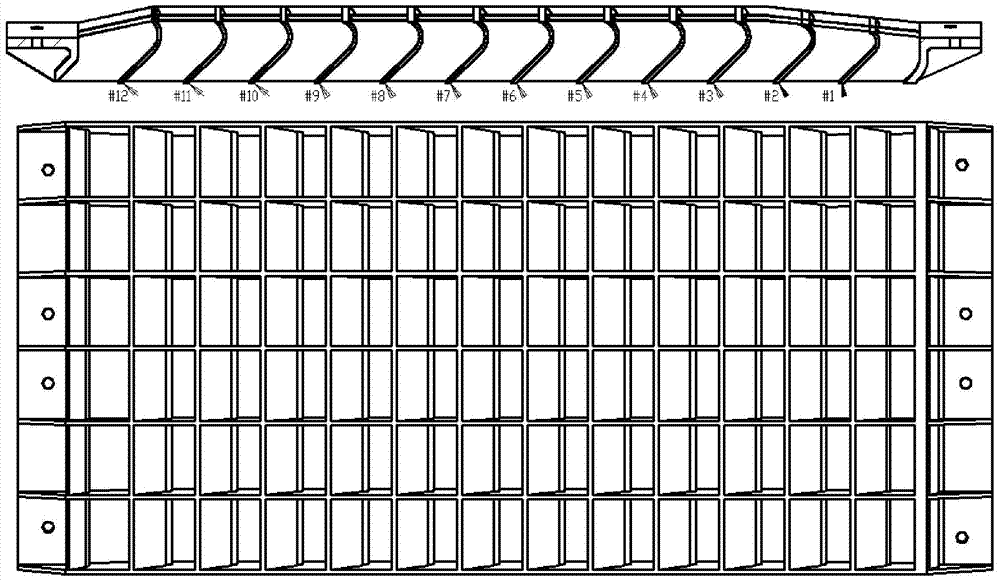

[0026] Such as figure 1 As shown, the grid is composed of 90 grids of different sizes and specifications; because the 90 grids of the grid are of different sizes and sizes, the traditional metal hard mold layering is used for forming, and the hard mold mold is complicated and the molding process is complicated.

[0027] Such as Figure 4 As shown, the embodiment of the present invention provides a RTM forming method of a grid, the method includes the following steps:

[0028] Step 1 Prepare a special metal hard mold:

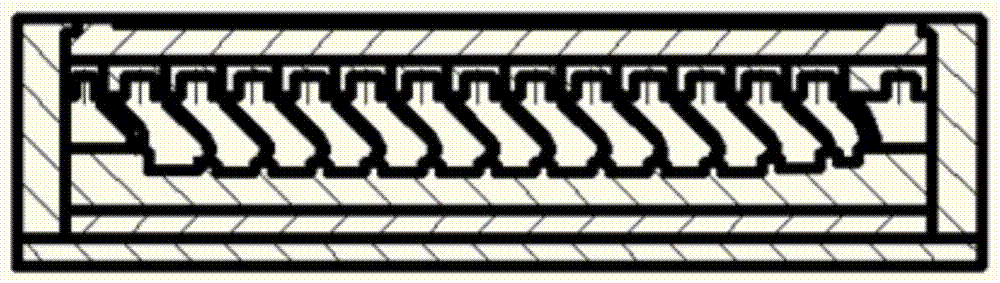

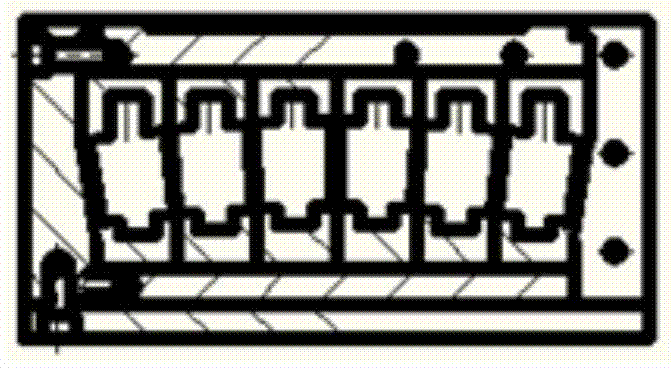

[0029] According to the grid structure, design a special metal hard mold, figure 2 It is a special metal hard mold used in the forming method of the grid of the present invention, image 3 for figure 2 view, such as figure 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com