Integrated solid wood panel of embedded structure

A mosaic structure and glulam technology, which is applied to wood processing appliances, wooden veneer joints, manufacturing tools, etc., can solve problems such as cracking, distortion, deformation, etc., and achieve the effect of wide selection of materials, low material cost, and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Now in conjunction with accompanying drawing and embodiment the present invention is described in detail:

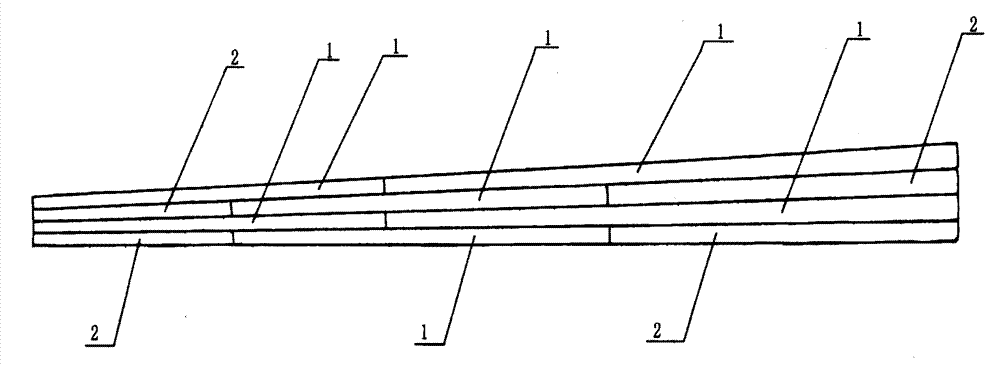

[0044] The present invention is made up of square bar one (1) and square bar two (2).

[0045] figure 1 Shown is the structural representation of the present invention. Wherein, 1 is square bar one (1), and 2 is square bar two (2).

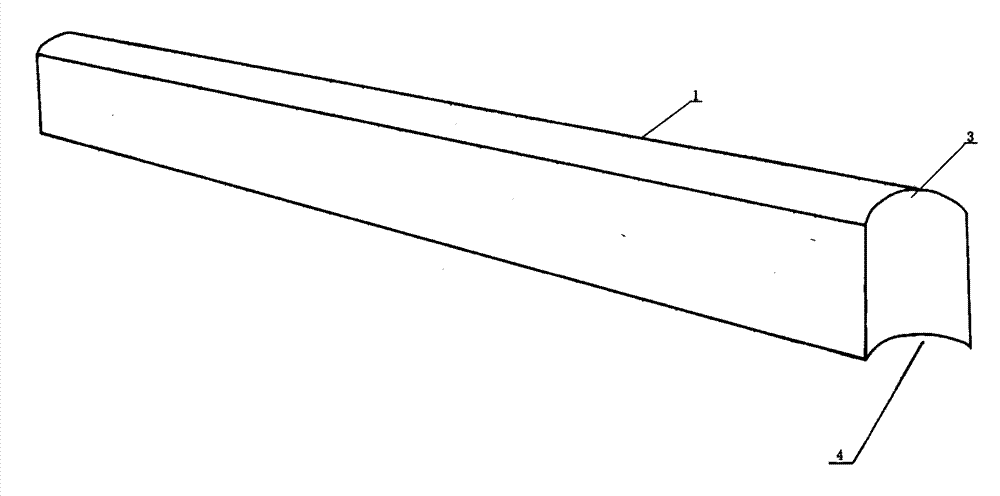

[0046] figure 2 Shown is the structural representation of square bar one (1) in the present invention. Square bar one (1) is a wooden bar with a square shape and a solid structure, and an arc-shaped tenon (3) is arranged on the chordwise top of the wooden bar, and an arc-shaped mortise (4) is arranged on the chordwise bottom of the wooden bar; , the structure of the arc-shaped tenon (3) is consistent with the structure of the arc-shaped tenon (4).

[0047] image 3 Shown is the structural representation of square bar two (2) in the present invention. Its body structure of square bar two (1) is consistent with square bar one (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com