Dry granulator inclined extrusion system

A dry granulator, inclined technology, applied in the direction of raw material extrusion granulation, mold extrusion granulation, etc., can solve the problems of transmission parts stuck, cross-contamination of drugs, easy to block materials, etc., to improve adaptability, Easy to disassemble and clean, temperature controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

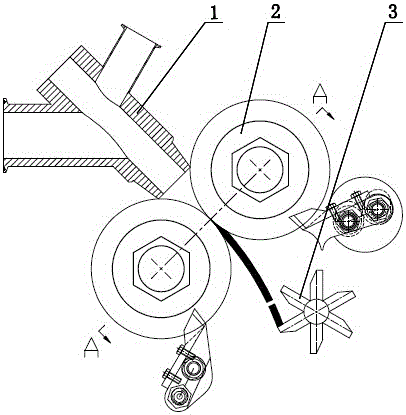

[0031] The positional relationship between the inclined extrusion system 2 of the dry granulator of the present invention and the conveying system 1 and the crushing system 3 is as follows: figure 1 As shown, the material enters the inclined extrusion system 2 through the conveying device to make high-density flakes, and then is cut into small pieces by the crushing knife of the crushing system 3 and enters the subsequent process.

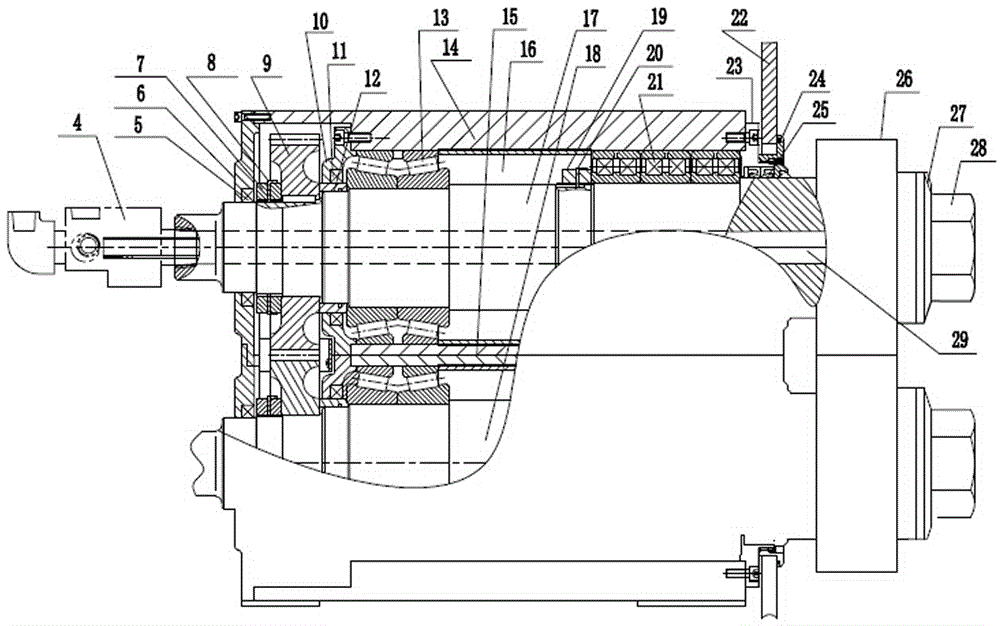

[0032] Such as Figure 2-7 As shown, the inclined extrusion system of the present invention includes a power device, a drive shaft 18 directly driven by the power device, a driven shaft 17 meshed with the drive shaft through a gear pair, and a pressure roller 26. The drive shaft 18 is arranged in the lower box 15, the driven shaft 17 is arranged in the upper box body 14, and the same end of the upper box body 14 and the lower box body 15 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com