Anthropomorphic phantom manufacturing method based on radiation detection

A technology for simulating human body and manufacturing method, which is applied in the comprehensive application field of interdisciplinary science, engineering and medicine, can solve the problems of lack of semi-finished products and finished products of the system, affecting the quality of medical images, lack of non-uniform structure and mosaic structure of human body models, etc., to save energy. efficient, convenient medical image processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

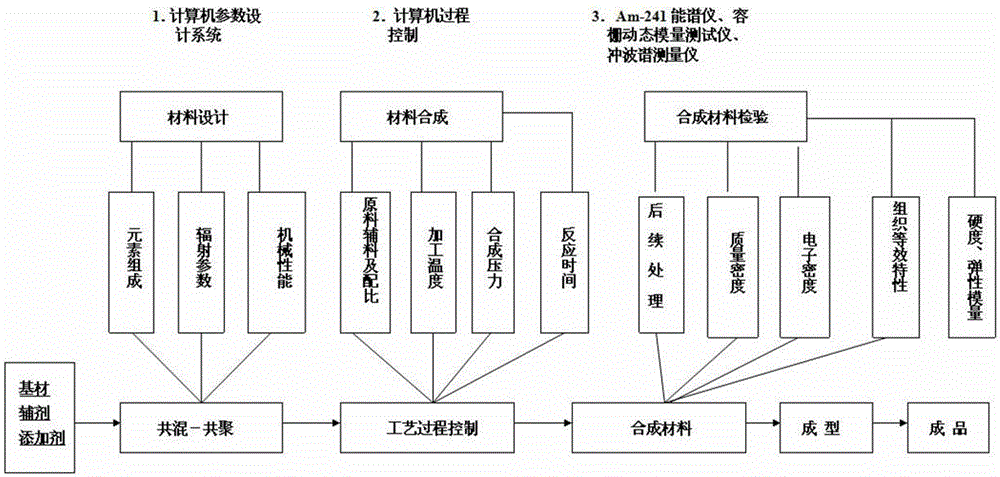

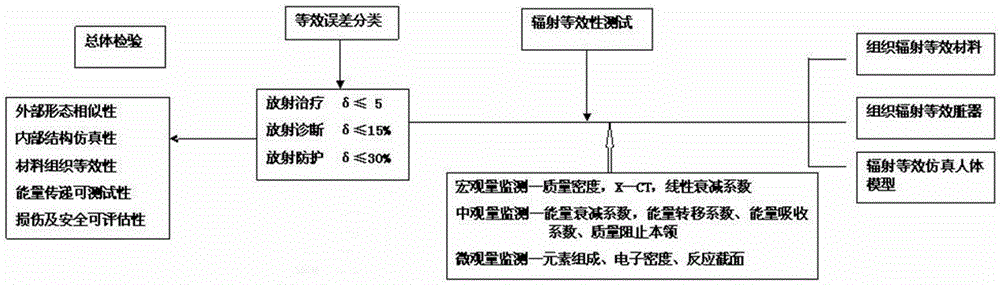

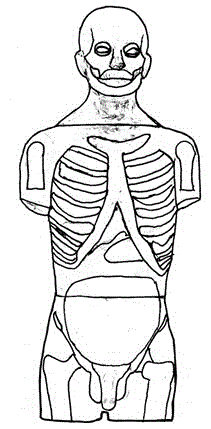

[0034] figure 1 It is the preparation process flow of the simulation human skin muscle of the present invention; figure 2 It is the equivalence judgment and grading flowchart of the radiation equivalent material of the present invention; image 3 It is a schematic diagram of the overall appearance of the human body model of the present invention; Figure 4 It is the internal section of the human body model of the present invention; Figure 5 It is the actual measurement and theoretical calculation diagram of the human body model; Image 6For the application of the human body model of the present invention in medical experiments, it can be seen that the human body model of the present invention can be used in medical imaging research, and the image image has a high similarity with the human body and has good equivalence.

[0035] The present invention designs based on the following design principles:

[0036] 1. Establish a mathematical model to achieve geometric similar...

Embodiment 1

[0077] Example 1: A method for manufacturing simulated human skin and muscle based on radiation detection, specifically comprising the following steps:

[0078] (1) Polymer formation: In a vacuum environment, polymethylene polyphenyl polyisocyanate and polyether polyol are reacted at a mass ratio of 1:3 to form a prepolymer, and a partial crosslinking reaction is used to expand Then the prepolymer was mixed with L580 silicone oil, titanic acid coupling agent, 1,4-butanediol, lecithin and protease, reacted for 12 hours at normal temperature and pressure, and slowly extended chain polymerization to form a growth type Situation, achieve material uniformity, and reduce cracks caused by internal stress; among them, titanic acid coupling agent accounts for 0.5% of the mass of the prepolymer material, L580 silicone oil, 1,4-butanediol, lecithin and protease each account for 1% of the mass of the prepolymer material;

[0079] The above polymethylene polyphenyl polyisocyana...

Embodiment 2

[0082] Example 2: A method for manufacturing simulated human skin and muscle based on radiation detection, specifically comprising the following steps:

[0083] (1) Polymer formation: In an inert gas helium environment, polymethylene polyphenyl polyisocyanate and polyether polyol were reacted at a mass ratio of 1:4 to form a prepolymer. The molecular weight is expanded through a joint reaction; then the prepolymer is mixed with L580 silicone oil, titanic acid coupling agent, 1,4-butanediol, methyl cellulose and protease, and reacted at room temperature and pressure for 18 hours to slowly extend the chain Polymerization, forming a growth-type situation, achieving material uniformity, and reducing cracks caused by internal stress; among them, titanic acid coupling agent accounts for 0.8% of the mass of the prepolymer material, L580 silicone oil, 1,4-butanediol, Methylcellulose and protease each account for 1% of the mass of the prepolymer material;

[0084] The abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com