Factory hidden danger identification method and system

A hidden danger investigation and factory technology, applied in the field of on-site safety management, can solve problems such as insufficient coverage and functional level, single source of hidden danger information, reduce accident rate, accident injury, loss degree, etc., to optimize the use experience, avoid The effect of clutter and disorder, simplifying the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

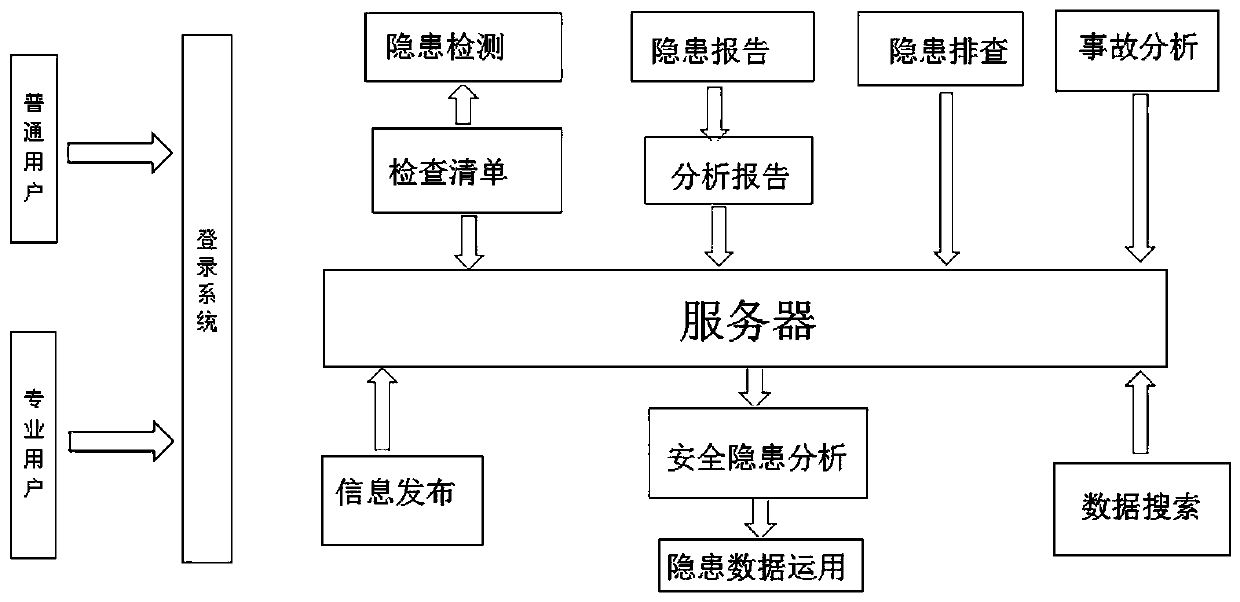

[0029] Such as figure 1 , a method for checking a hidden danger checking system in a factory, comprising the following steps:

[0030] In the inspection step, the inspector creates a new inspection task by logging in to the account on the handheld terminal, and the task controller identifies the identity of the inspector and the task type to obtain the information corresponding to the inspection task, then the task controller retrieves the inspection task list corresponding to the inspection task from the database. The inspection project generation template generates a task list and sends it to the inspector's hand-held terminal. The inspector performs the inspection work according to the content of the task list and fills back the task list. After the task list is completed, it is sent back to the task controller, and the task controller writes the task list. Enter the database, and assign the problems found in the task list to the account of the corresponding person in charg...

Embodiment 2

[0035] Such as figure 1 , a method for checking a hidden danger checking system in a factory, comprising the following steps:

[0036] In the inspection step, the inspector creates a new inspection task by logging in to the account on the handheld terminal, and the task controller identifies the identity of the inspector and the task type to obtain the information corresponding to the inspection task, then the task controller retrieves the inspection task list corresponding to the inspection task from the database. The inspection project generation template generates a task list and sends it to the inspector's hand-held terminal. The inspector performs the inspection work according to the content of the task list and fills back the task list. After the task list is completed, it is sent back to the task controller, and the task controller writes the task list. Enter the database, and assign the problems found in the task list to the account of the corresponding person in charg...

Embodiment 3

[0045] Such as figure 1 , a factory hidden danger investigation system, including an inspection subsystem connected to a server with a database and a task controller, a hidden danger reporting subsystem, and a safety accident analysis subsystem; the inspection corresponding to the items to be inspected is entered in the database task list, typical accident analysis data and inspection project generation template; the task controller includes a task calling program, a task writing program, a task assignment program and an inspector management program; the inspector logs in an account to create a new inspection task, and the task controller Identify the inspector level and task type, call the corresponding inspection task list from the database and send it to the inspector. After the inspector completes the inspection, he will send the inspection record and the problems found back to the task controller. The task controller will write the inspection record into the database and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com