Detection system and detection method for cracks in bridge undersurface

A crack detection and bridge technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of low detection efficiency, large detection limitations, and non-standard detection results, so as to reduce the detection cost, simplify the operation difficulty, and ensure the calculation accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the following, the concept, specific structure and technical effects of the present invention will be further described in conjunction with the accompanying drawings to fully understand the purpose, features and effects of the present invention.

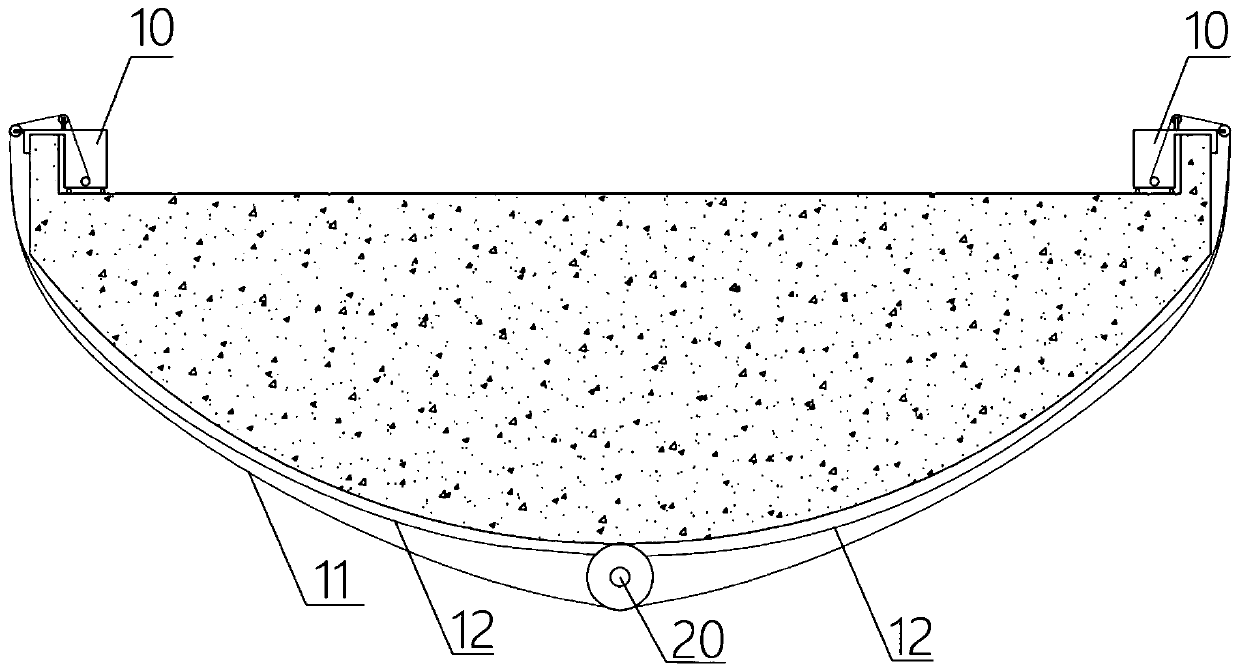

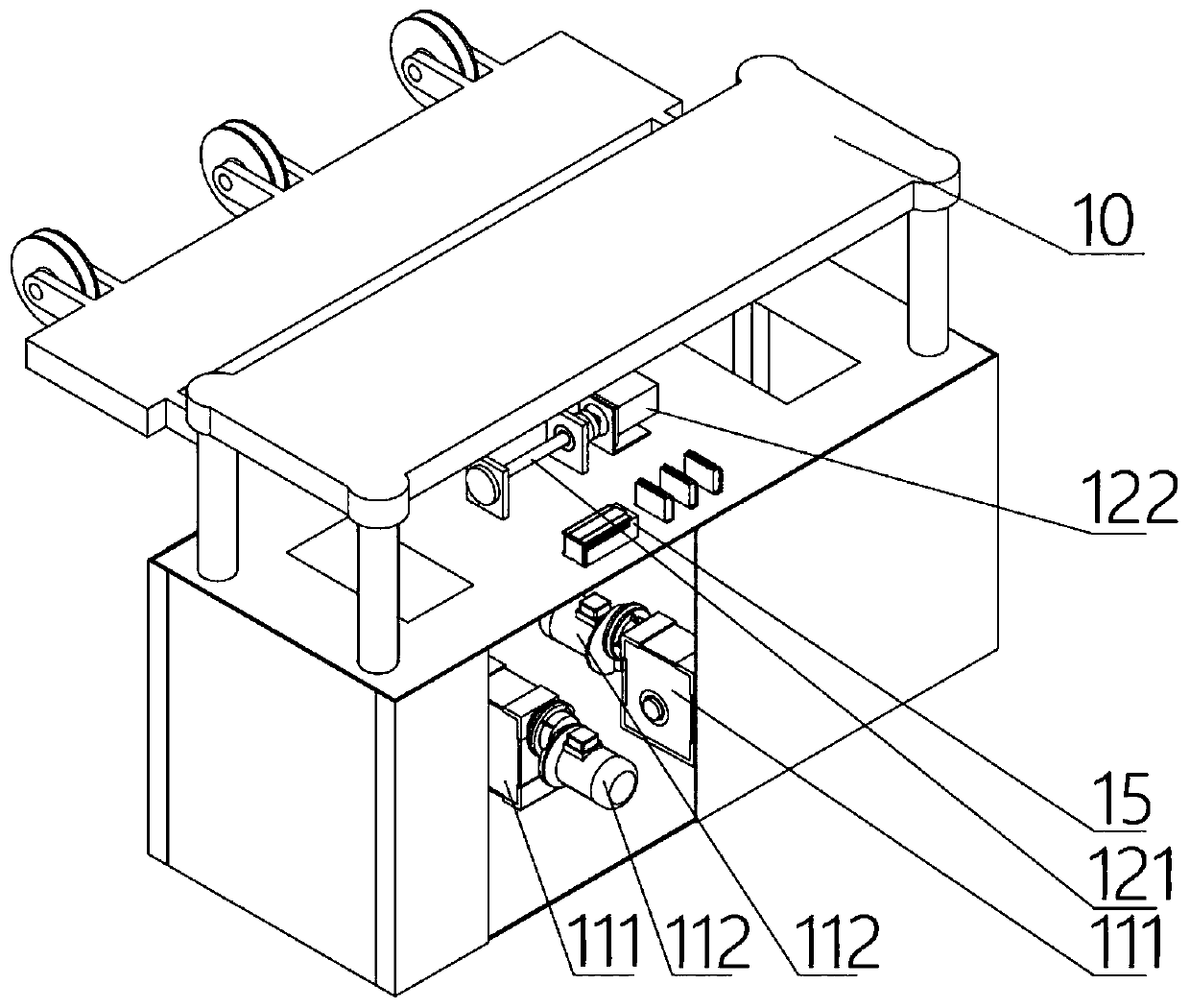

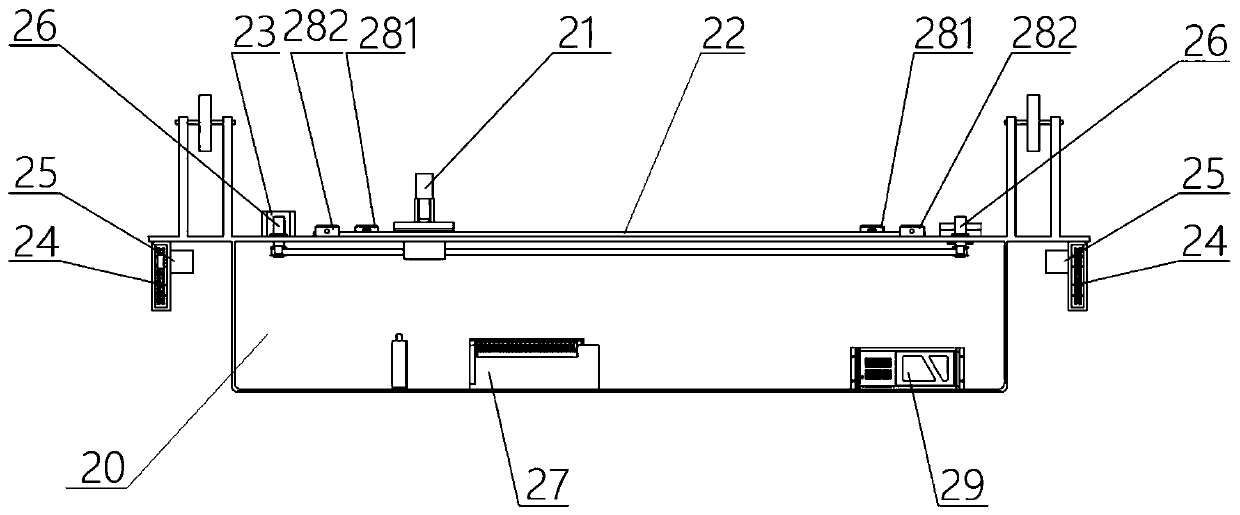

[0041] reference figure 1 The bridge bottom crack detection system of the present invention includes a cable tractor 10 running on both sides of the bridge and a crack detection vehicle 20 under the bridge. The cable tractor 10 provides support and moving power for the crack detection vehicle 20, and crack detection The car 20 performs the task of shooting and collecting crack information. A load-bearing cable 11 is connected between the cable tractors 10 on both sides of the bridge deck. The load-bearing cable 11 is hung below the bridge. The crack detection vehicle 20 uses the load-bearing cable 11 as a load-bearing and moving track and is pulled by the cable-towing vehicle 10 along the bridge. Move in the length direction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com