Uncertainty compensatory sliding-mode control method of hydraulic position servo system

A servo system and uncertainty technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as system instability, modeling uncertainty, deterioration of theoretical analysis tracking performance, etc., to reduce Effects of gain, enhanced ability to resist match and mismatch uncertainties and non-linearities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

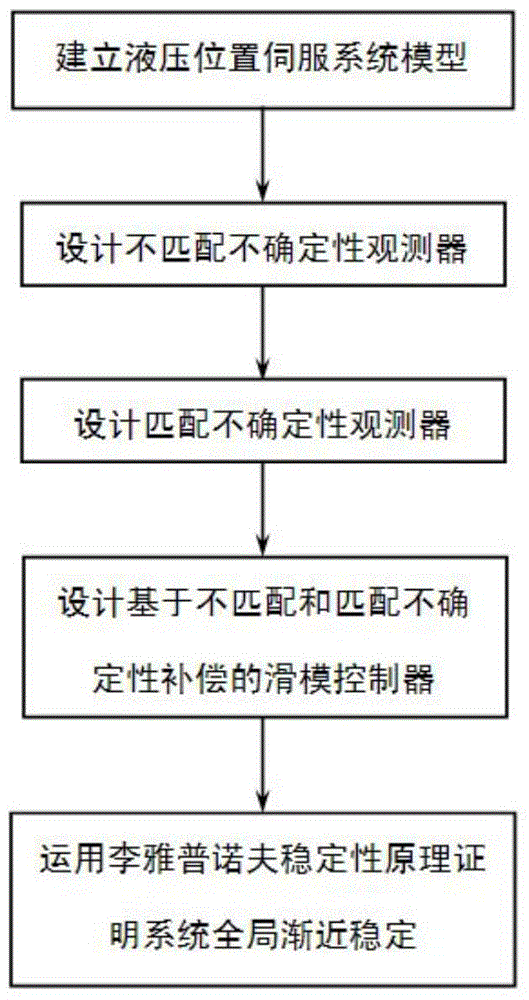

Method used

Image

Examples

Embodiment 1

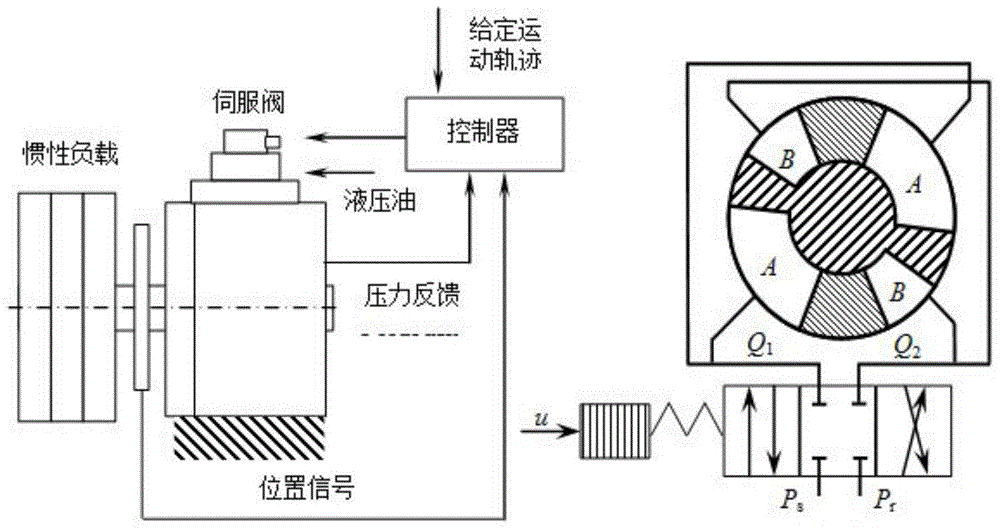

[0135] combine Figure 1 ~ Figure 3 , in order to assess the performance of the designed controller, the following parameters are taken in the simulation to model the electro-hydraulic position servo system:

[0136] Load moment of inertia m=40kg·m 2 , Motor displacement A=2×10 -4 m 3 / rad, viscous friction coefficient B=80N m s / rad, oil supply pressure P s =7MP a , return oil pressure P r =0, oil elastic modulus β e =2×10 8 P a , the initial volume V of the two chambers of the motor 01 =V 02 =1×10 -3 m 3 , leakage coefficient C t =9×10 -12 m 3 / s / P a , total flow gain Pressure dynamic modeling error q 1 (t)=q 2 (t)=6×10 -6 m 3 ·rad / s, external load interference f(t)=200[1-exp(-0.1t 3 )] (N·m).

[0137] The desired instruction for a given system is x 1d =sin(t)[1-exp(-0.01t 3 )] (rad).

[0138] Take the following controller for comparison:

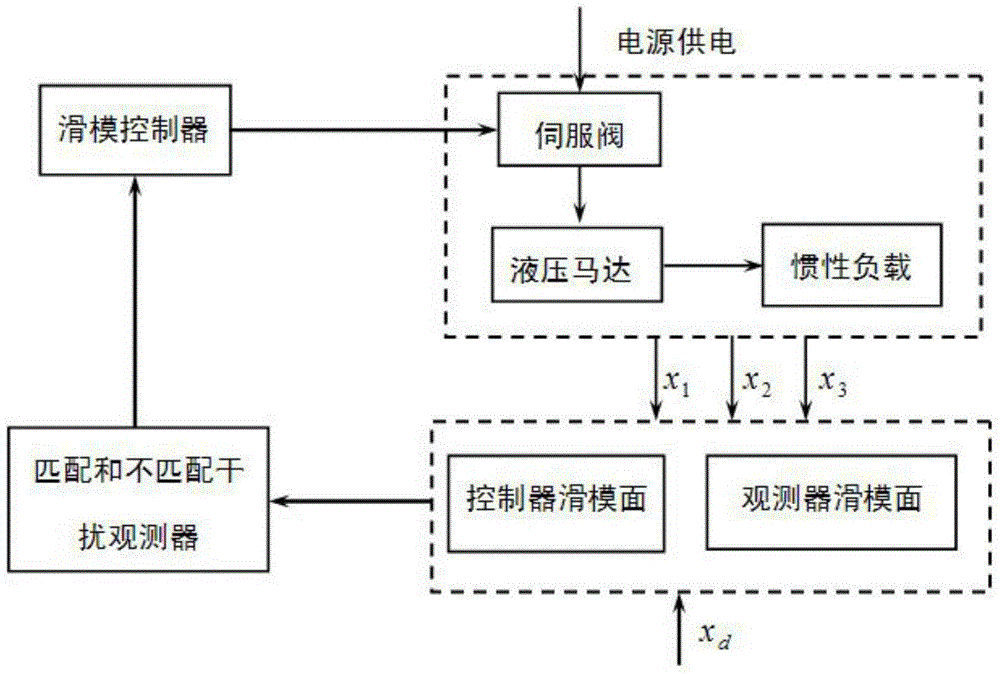

[0139] Sliding Mode Controllers for Matched and Mismatched Uncertainty Compensation: Taking the Mismatched Dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com