Tank calciner U-shaped open circulation cooling system and cooling method

A circulating cooling system and tank-type calciner technology, which is applied in the direction of furnace cooling, furnace, furnace components, etc., can solve the problems that the return water system cannot be monitored, the top of the water jacket is empty, and the cooling efficiency is low, so as to increase the effective heat transfer Area, avoid empty burning, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

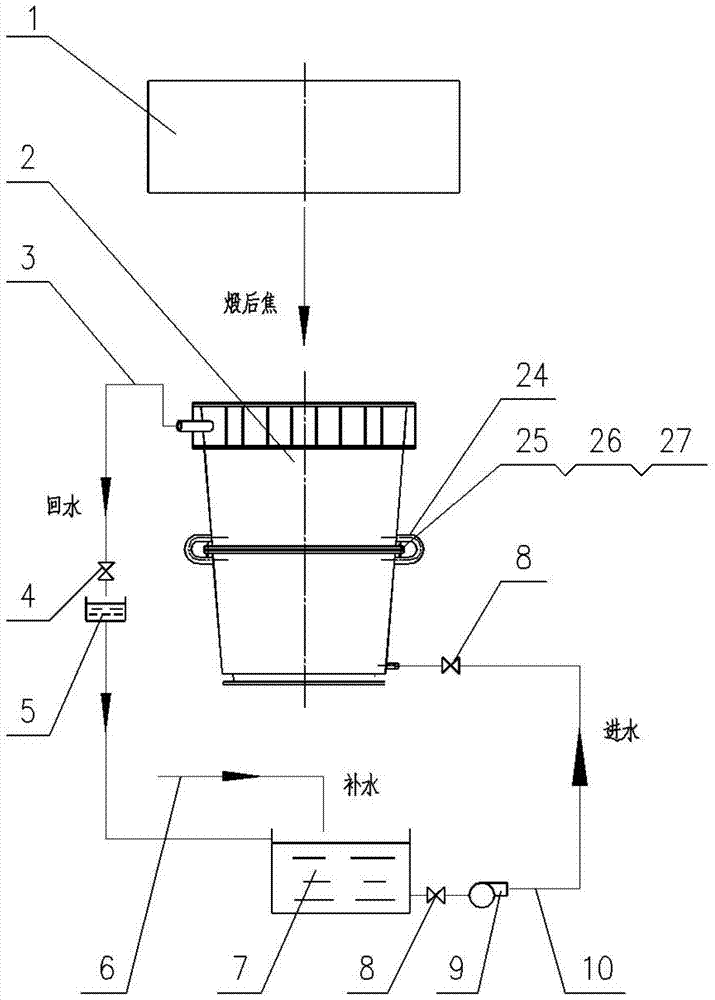

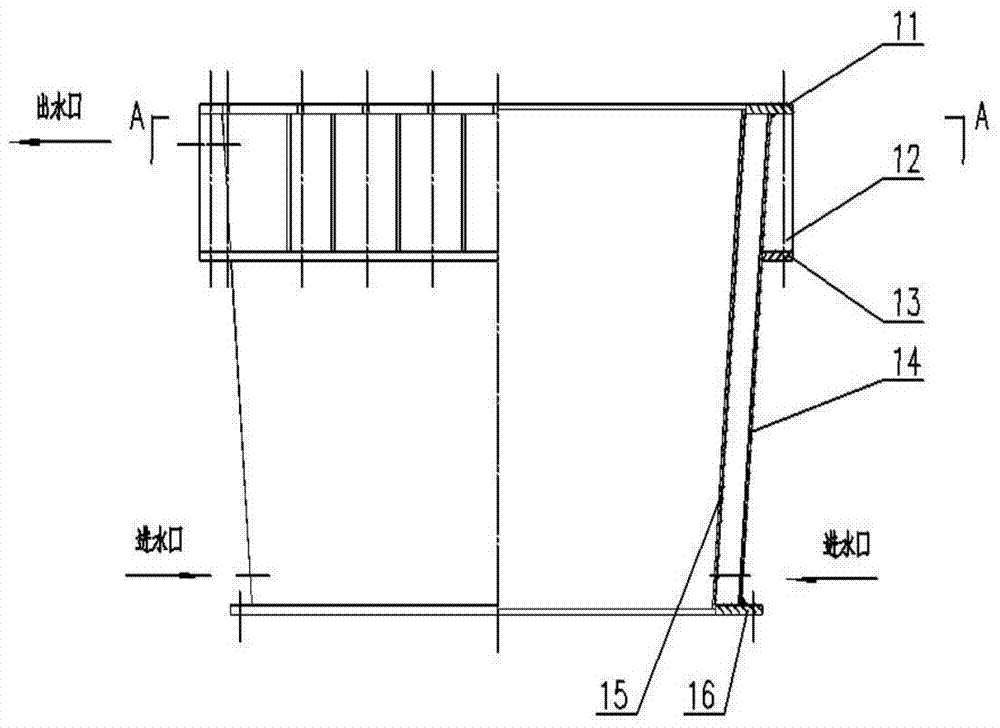

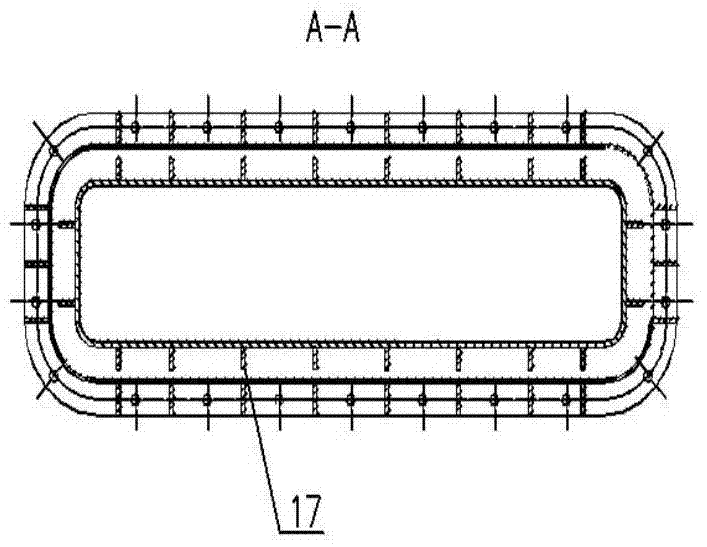

[0041] like Figure 1-Figure 5 As shown, the U-shaped open circulation cooling system of the pot calciner of the present invention mainly includes a pot calciner 1, a cooling water jacket 2, a U-shaped return water pipe 3, a return water stop valve 4, a cup-shaped container 5, and a water supply pipe 6 , Reservoir 7, Water inlet stop valve 8, Circulating water pump 9, Water inlet pipe 10, Flange Ⅰ11, Rib 12, Flange Ⅱ13, Outer steel plate Ⅰ14, Inner steel plate Ⅰ15, Flange Ⅲ16, Fin Ⅰ17, Flange Ⅳ18, outer steel plate Ⅱ19, inner steel plate Ⅱ20, flange Ⅴ21, flange Ⅵ22, fin Ⅱ23, connecting pipe 24, bolt 25, nut 26, gasket 27, etc. The specific structure is as follows:

[0042]The cooling water jacket 2 and the reservoir 7 are connected through a return water channel, and a cup-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com