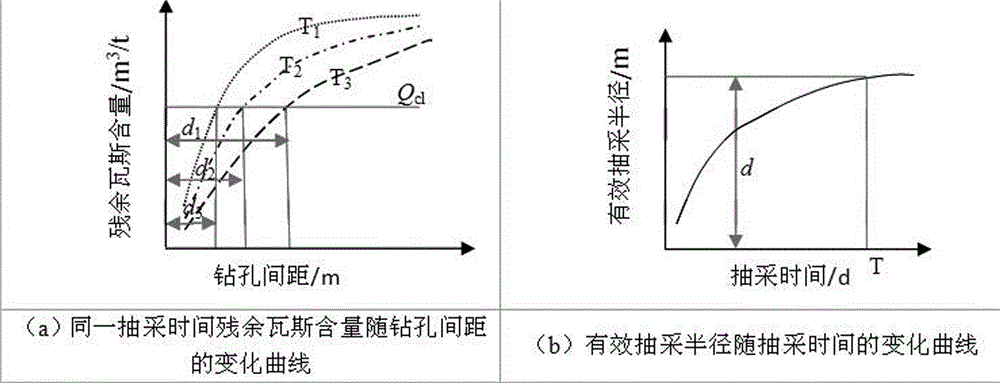

Measuring Method of Effective Radius of Borehole Drainage Gas Based on Residual Gas Content

A technology of gas content and drainage radius, which is applied in the field of testing the effective radius of gas drainage in boreholes, can solve the problems of large measurement errors, high difficulty coefficients, and difficulty in measuring the gas pressure of coal seams, so as to reduce the difficulty of drilling, Effect of reducing error in measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Embodiment 1 step type residual gas content determination method

[0075] (1) In the pre-pumping area, select the area with simple structure and stable coal seam occurrence according to the "Direct Measuring Method of Coal Seam Gas Content Underground" to drill hole A, vertical coal wall construction, diameter 42mm; after drilling 15m, every 2~3m Sampling to measure coal seam gas content, at least 3 sets of data (Q 1 , Q 2 , Q 3 ...), take the average value as the average gas content Q before pre-pumping 均 The research shows that: the pressure relief zone of the coal wall is 10-15m, and the gas content measured in the pressure relief zone is low; at the same time, the "Direct Measurement Method of Coal Seam Gas Content Underground" stipulates: when sampling and measuring the gas content in the mining face, The sampling depth should not be less than 12m. Therefore, in order to accurately measure the residual gas content, it is usually measured after the drilling dept...

Embodiment 2

[0101] Embodiment 2 group residual gas content determination method

[0102] When measuring the effective radius of drilling gas drainage in a soft coal seam, it is difficult to investigate the drilling in the construction oblique direction, and it is difficult to take coal samples. The group residual gas content measurement method can be used, and the steps are:

[0103] (1) In the pre-pumping area, select the area with simple structure and stable coal seam occurrence, and the vertical coal walls at the same horizontal height are separated by different distances. According to the gas occurrence situation, a group of conventional drainage borehole;

[0104] (2) For this group of drainage boreholes, conduct sealing and joint drainage, and continuously measure the drainage concentration and drainage flow. After a period of time of extraction, according to the "Direct Measurement Method of Underground Gas Content in Coal Seams", drill holes 1', 2', 3', and 4' were constructed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com