Method for improving shock absorption effect and stability of downhole drilling tool and downhole drilling tool

A technology of stability and drilling tools, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of destroying the working environment of the drill bit, reducing the service life of the drill bit, and breaking the drill bit due to torsional impact, so as to improve the drilling speed and well Improve the quality of the drill bit, improve the life of the drill bit, and simplify the structure of the drill tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as any limitation to the present invention.

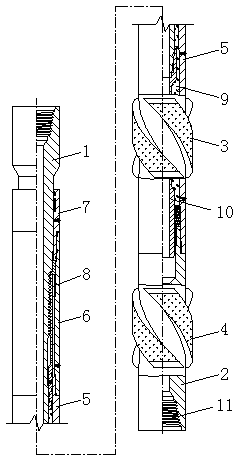

[0020] Embodiments of the present invention: a method of improving the vibration reduction effect and stability of the downhole drilling tool of the present invention can be implemented on the existing lower joint and mandrel structure, such as figure 1 As shown, the method is to install a hydraulic shock absorber between the lower joint and the mandrel to eliminate or slow down the up and down vibration caused by jumping drill; at the same time, a stabilizer is installed at the lower part of the hydraulic shock absorber and the upper part of the lower joint to prevent the drilling tool from producing lateral vibration. The displacement caused the well deviation. The hydraulic shock absorber is a cylindrical oil cylinder filled with compressible liquid, which can eliminate or slow down the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com