Electrophoresis pretreatment process for vehicle parts

A technology for parts and motor vehicles, which is applied in the field of electrophoresis pretreatment process of motor vehicle parts, can solve the problems affecting the treatment effect of parts, and achieve the goal of simple and easy process implementation, improved removal effect, and reduced operation and maintenance difficulty and cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The core of the present invention is to provide an electrophoresis pretreatment process for motor vehicle parts, which requires less equipment maintenance and is simple and easy to implement.

[0028] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

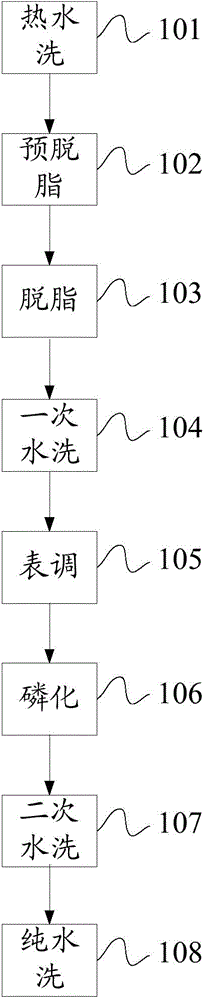

[0029] Please refer to figure 1 , figure 1 It is a flow chart of the electrophoresis pretreatment process for motor vehicle parts provided by a specific embodiment of the present invention.

[0030] The electrophoresis pretreatment process for motor vehicle parts provided by the invention includes:

[0031] Step 101: washing with hot water;

[0032] Preliminary cleaning of the workpiece with hot water is carried out by dipping treatment. Among them, the temperature of the bath solution for hot water washing is controlled at 50°C to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com