Process for preparing high-light-absorption-rate black ceramic film layer through micro-arc oxidation of surface of magnesium alloy

A micro-arc oxidation and black ceramic technology, applied in the black ceramic film preparation process and the black ceramic film technology field, can solve the problems of complex electrolyte composition and high processing cost, and achieve high light absorption performance, high blackness, and film. The effect of high layer density and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of the black micro-arc oxidation ceramic film layer on the surface of magnesium alloy, the specific preparation process conditions and operation steps are as follows:

[0025] 1) Pre-treatment of the sample: polish the flake magnesium alloy smoothly, then ultrasonically clean it with acetone and water respectively, and dry it for later use;

[0026] 2) Electrolyte configuration: weigh 20g sodium silicate, 12.5g sodium phosphate, 8g ammonium fluoride, 6g sodium vanadate, 4g ammonium metavanadate, mix well, add 1L water, stir, fully dissolve and set aside;

[0027] 3) Electrical parameter setting: constant current mode, current density 15A / dm 2 , frequency 175Hz, duty cycle 30%, positive and negative pulse current ratio 1:1, response time 15min;

[0028] 4) Micro-arc oxidation on the surface of the magnesium alloy: use the above-mentioned treated magnesium alloy sample as the anode, completely immerse in the above-mentioned electrolyte ...

Embodiment 2

[0034] The preparation method of the black micro-arc oxidation ceramic film layer on the surface of magnesium alloy, the specific preparation process conditions and operation steps are as follows:

[0035] 1) sample pretreatment: with embodiment 1;

[0036] 2) Electrolyte configuration: weigh 15g sodium silicate, 20g sodium phosphate, 6g ammonium fluoride, 8g sodium vanadate, 2g ammonium metavanadate, mix well, add 1L water, stir, fully dissolve and set aside;

[0037] 3) Electrical parameter setting: constant current mode, current density 16.7A / dm 2 , frequency 200Hz, duty cycle 20%, positive and negative pulse current ratio 1:1, response time 20min;

[0038] 4) micro-arc oxidation on the surface of magnesium alloy: same as embodiment 1;

[0039] 5) post-processing: with embodiment 1.

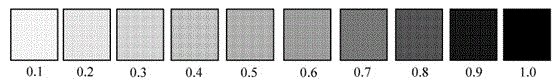

[0040] The prepared micro-arc oxidation ceramic film was evaluated and characterized. The blackness of the black ceramic film reached 0.8; the average thickness of the cerami...

Embodiment 3

[0042] The preparation method of the black micro-arc oxidation ceramic film layer on the surface of magnesium alloy, the specific preparation process conditions and operation steps are as follows:

[0043] 1) sample pretreatment: with embodiment 1;

[0044] 2) Electrolyte configuration: Weigh 10g sodium silicate, 5g sodium phosphate, 12g ammonium fluoride, 5g sodium vanadate, 5g ammonium metavanadate, mix well, add 1L water, stir, fully dissolve and set aside;

[0045] 3) Electrical parameter setting: constant current mode, current density 20A / dm 2 , frequency 175Hz, duty cycle 30%, positive and negative pulse current ratio 2:1, response time 30min;

[0046] 4) micro-arc oxidation on the surface of magnesium alloy: same as embodiment 1;

[0047] 5) post-processing: with embodiment 1.

[0048] The prepared micro-arc oxidation ceramic film was evaluated and characterized. The blackness of the black ceramic film reached 1.0; the average thickness of the cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com