Solid clothes laundering composition coated with polymeric membrane and preparation method thereof

A polymer film and composition technology, applied in detergent compositions, organic cleaning compositions, anionic-cationic-nonionic surface active compounds, etc., can solve the problems of biological death, low safety, high packaging cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

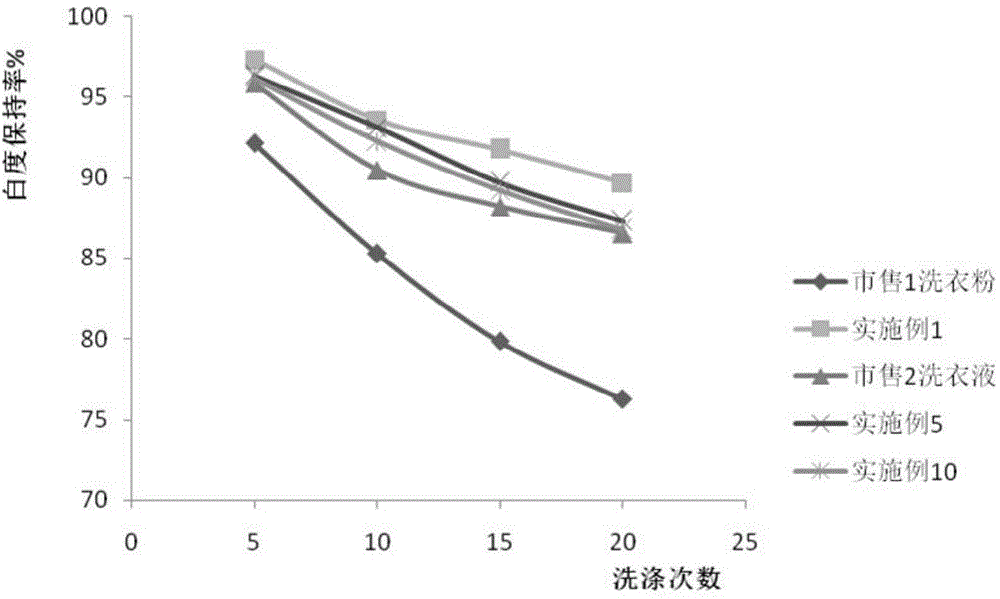

Examples

Embodiment 1~10

[0029] (1) Polymer film that resists redeposition and complexes calcium and magnesium ions:

[0030] Preparation method: Add water to the anti-redeposition agent in the formula and disperse until completely dissolved, add scale inhibitor dispersant and auxiliary materials, heat to 50-100°C, dissolve evenly, pour it on the plate or roller, and scrape it thin with a scraper , after drying, cut into suitable size and set aside.

[0031] The selection and mass percentage of each raw material component are shown in Table 1.

[0032] Table 1 Unit: %

[0033]

[0034]

[0035] The polymer film of the present invention is not limited to the above-mentioned proportioning method, and other proportioning methods can also be used for proportioning.

[0036] (2) Washing material:

[0037] Preparation of washing material: anionic surfactant, cationic surfactant, nonionic surfactant and washing aid are mixed and stirred evenly, and each embodiment is made into 10g, 20g, 30g of solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com