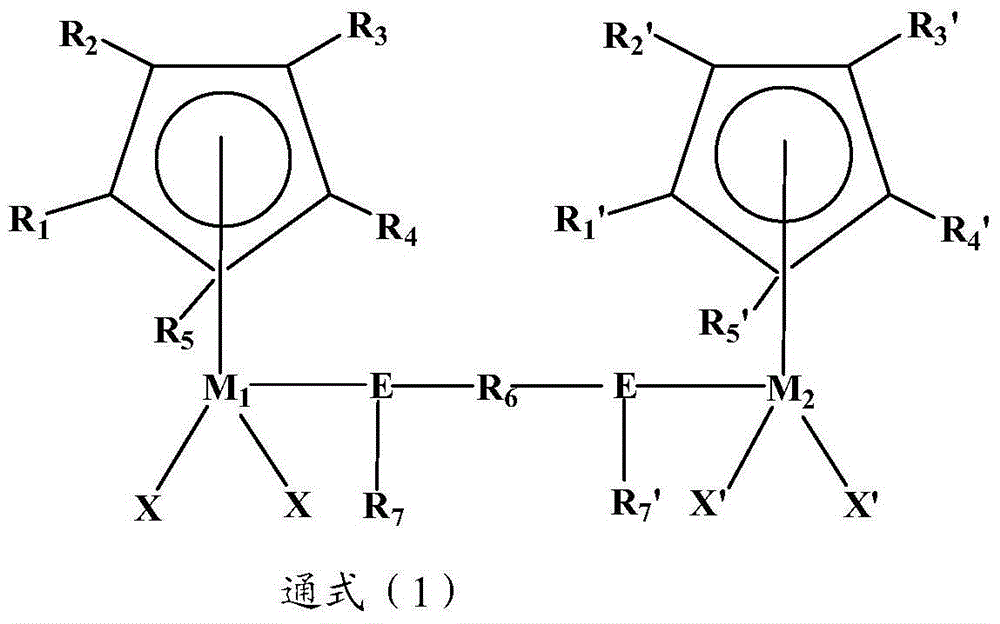

Bi-metal semi-metallocene catalyst and preparation method and application thereof

A catalyst and bimetallic technology, applied in the fields of olefin polymerization organometallic catalysts and olefin coordination polymerization, can solve problems such as the complex molecular structure of metallocenes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

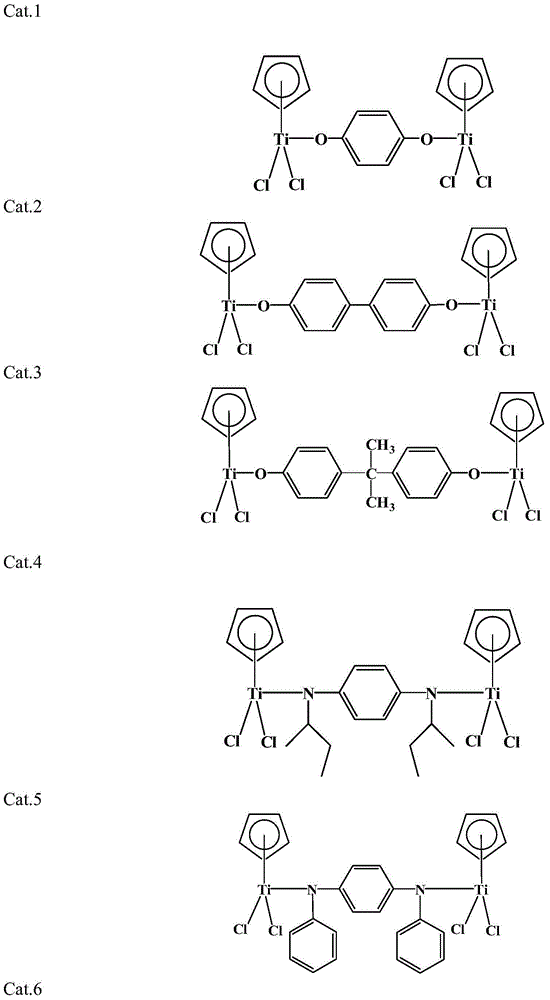

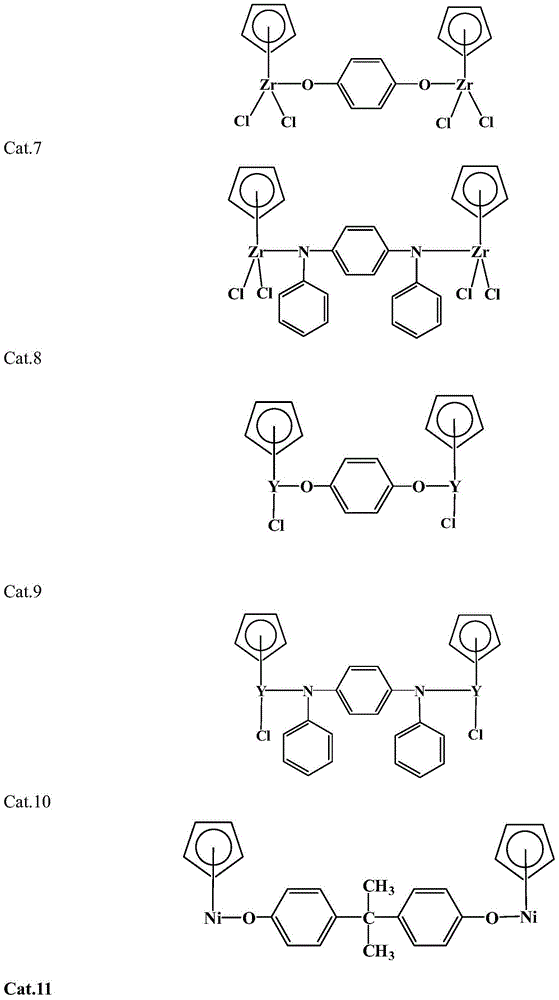

[0052]1) Preparation of metallocene catalyst: under anhydrous, oxygen-free and nitrogen protection, add 100mL toluene to a 250mL reaction flask, and add 3.3mL (0.04mol) cyclopentane successively at room temperature (open system under standard atmospheric pressure, the same below). Diene, 3.8mL (0.04mol) of n-butyllithium, reacted for 2h; heated to 40°C, reacted for 4h. At 0°C, 4.4 mL (0.04 mol) of TiCl was added to the intermediate 4 , and reacted at 0° C. for 1 h; subsequently, reacted at room temperature for 3 h; suction filtered, and washed the solid matter with n-hexane three times; suction filtered at 30° C. to obtain compound M1 (see general formula (3)), and the yield was 95.6%.

[0053] 2) Preparation of the double metallocene catalyst: add 100mL of toluene to a dry reaction flask with a magnet under nitrogen protection, add 4.4g (0.02mol) of compound M1 and stir to dissolve, add 1.1g (0.01mol) at 10°C For hydroquinone, keep at 10°C for 30 minutes, then raise the temp...

Embodiment 2

[0057] 1) Preparation of the double metallocene catalyst: Add 100 mL of toluene to a dry reaction flask with magnets under the protection of anhydrous, oxygen and nitrogen, add 4.4 g (0.02 mol) of compound M1 and stir to dissolve, add 1.86 g (0.01mol) of 4,4'-diphenol, kept at 10°C for 30min, then raised to 40°C for 3h. After the reaction finishes, filter and wash several times with n-hexane 50mL at 40°C, and suction filter; obtain the main catalyst component Cat.2:

[0058] 2) Ethylene polymerization: Under anhydrous and oxygen-free conditions, add 100 mL of toluene, 10 mg of main catalyst (Cat.2), and 4.0 mL of MAO solution (1.5 mol / L) in sequence in a 250 mL reaction flask. After exchanging air for three times, keep polymerization at 160°C and 2 atm ethylene pressure for 30min, terminate the reaction with ethanol solution containing 10% (volume fraction, the same below) hydrochloric acid, filter, wash with ethanol three times, and vacuum the polymer at 40°C Dry for 24h. ...

Embodiment 3

[0061] 1) Preparation of the double metallocene catalyst: Add 100 mL of toluene to a dry reaction flask with magnets under the protection of anhydrous, oxygen and nitrogen, add 4.4 g (0.02 mol) of compound M1 and stir to dissolve, add 2.30 g (0.01mol) of bisphenol A, kept at 10°C for 30min, then raised to 40°C for 3h. After the reaction finishes, filter and wash several times with n-hexane 50mL at 40°C, and suction filter; obtain the main catalyst component Cat.3:

[0062] 2) Ethylene copolymerization: under anhydrous and oxygen-free conditions, add 100mL toluene, 10mg main catalyst (Cat.3), 4.5mL MAO solution (1.5mol / L), 5mL α-methylstyrene to a 250mL reaction flask in sequence . After exchanging air for three times, keep polymerization at 170°C and 2 atm ethylene pressure for 1h, stop the reaction with ethanol solution containing 10% hydrochloric acid, filter, wash with ethanol three times, and dry the polymer in vacuum at 40°C for 24h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com