Rosin triol ester as well as preparation method and application thereof

A technology of rosin triol ester and abietic acid trimethylolpropane ester, which is applied in the field of rosin triol ester and its preparation, to achieve the effects of expanding rosin industry, improving properties and making the preparation process safe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] 1. Preparation of trimethylolpropane dehydroabietate

[0058] The preparation method of a kind of rosin triol ester in the present invention is to take dehydroabietic acid and trimethylol propane as raw material, the dehydroabietic acid triol ester reaction that takes place in normal temperature under the presence of EDC / DMAP catalyst and organic solvent generates dehydroabietic acid triol Methyl propane ester, its reaction formula is as follows:

[0059]

[0060] The main instruments and reagents used for the preparation of trimethylolpropane dehydroabietate are:

[0061] Instrument: rotary evaporator (Xihuayi (Beijing) Co., Ltd.)

[0062] The column diameter used in column chromatography is 60mm*30mm

[0063] Infrared spectrometer (Nicolet IS10)

[0064] High performance liquid chromatography (Agilent1260-HPLC)

[0065] LC / MS (Shimadzu LCMS-2010A)

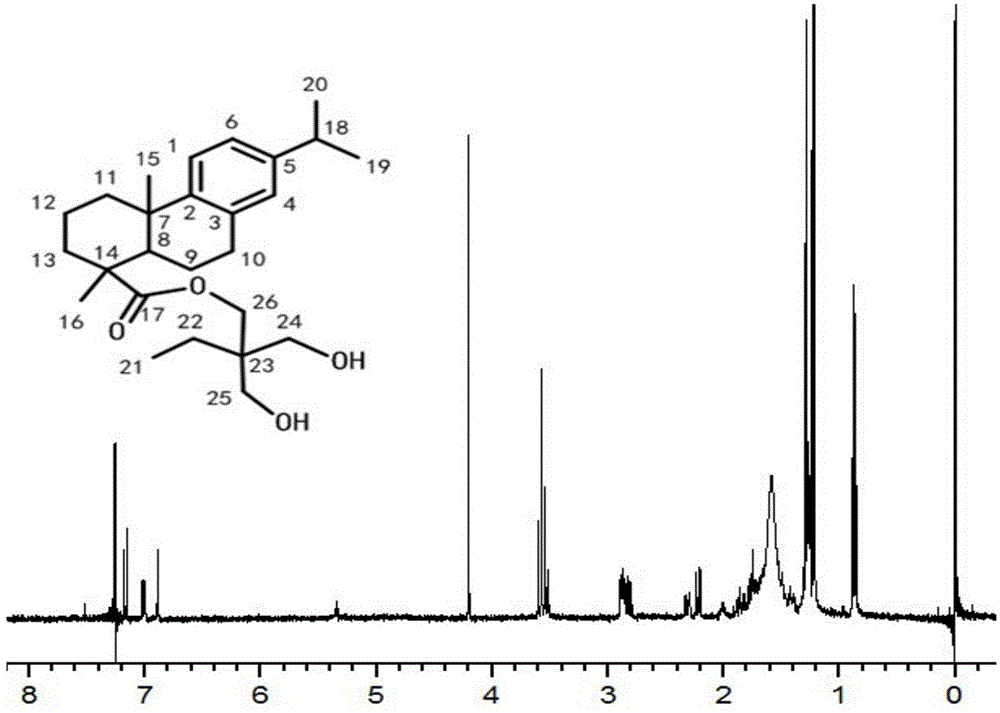

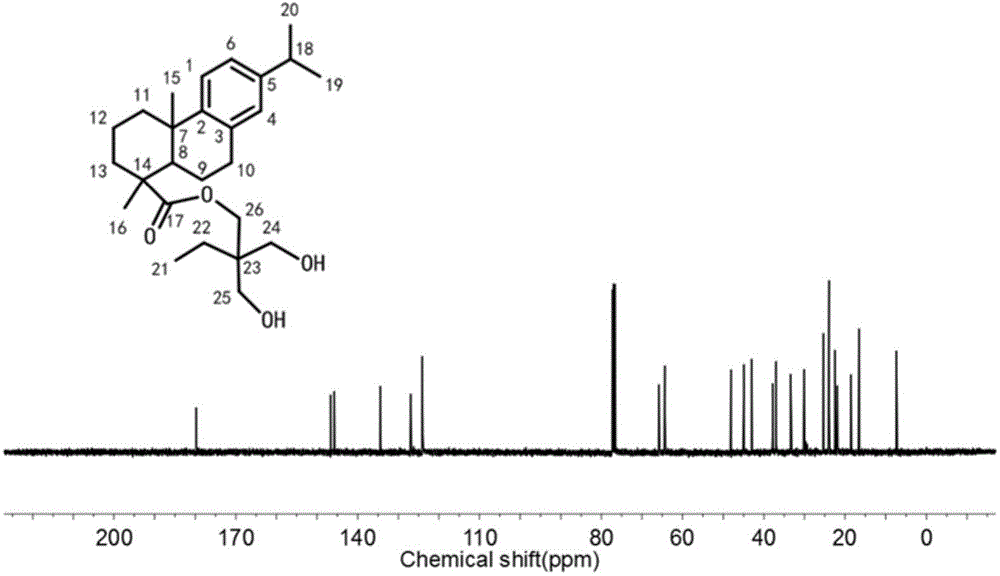

[0066] NMR spectrometer (Bruker Avance(600 / 400)MHz spectrometer)

[0067] Gel permeation chromatography (Waters...

Embodiment 1

[0071] A preparation method of trimethylolpropane dehydroabietic acid, using dehydroabietic acid and trimethylol propane as raw materials, the reaction is carried out in a water bath earlier, in a 250ml three-necked flask, feed nitrogen for 15 minutes, add Dehydroabietic acid (1eq, 1.5g, 0.005mol), trimethylolpropane (4.5eq, 3.015g, 0.024mol) and DMAP (4-dimethylaminopyridine) (1.6eq, 1g, 0.008mol), Dissolve in 20mL of N,N-dimethylformamide (DMF). After dissolving, add a large amount of ice cubes to the water bath, cool the temperature to 0°C, and quickly add EDC (1-(3-dimethylaminopropyl base)-3-ethylcarbodiimide) (1.2eq, 1.15g, 0.006mol), continue to pass nitrogen gas, after 15 minutes of reaction, remove the ice cubes, seal each port with a plug, and place in water at room temperature at 25°C Carry out the reaction, stop stirring continuously for 24 hours, and the reaction is completed. The material obtained by the reaction is transferred to a single-necked flask for rotary...

Embodiment 2

[0076] A kind of preparation method of dehydroabietic acid trimethylol propane ester, take dehydroabietic acid and trimethylol propane as raw material, reaction is carried out in water bath earlier, in 250ml there-necked flask, feed nitrogen 15 minutes, dehydroabietic acid

[0077] (1eq, 1.5g, 0.005mol), trimethylolpropane (1.2eq, 0.8g, 0.006mol) and DMAP (4-dimethylaminopyridine) (1.6eq, 1g, 0.008mol), dissolved in 25mL After dissolving in tetrahydrofuran, add a large amount of ice cubes to the water bath, cool the temperature to 0°C, and quickly add EDC (1-(3-dimethylaminopropyl)-3-ethylcarbodiimide) (1.2eq , 1.15g, 0.006mol), continue to blow nitrogen, after 20 minutes of reaction, remove the ice cubes, seal each port with a plug, react in water at room temperature 28 ° C, and stop stirring after 24 hours, the reaction is over, all The material was transferred to a single-necked flask and subjected to rotary evaporation using 80 mL of petroleum ether as a solvent on a rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com