Leaf green spray utilizing waste wort of alcohol as raw material for promoting potassium absorption and preparation method of leaf green spray

A technology of alcohol waste mash and spray, applied in the fields of botanical equipment and methods, biocides, insecticides, etc., can solve the problems of environmental pollution, suffocation of aquatic organisms, eutrophication, etc., to promote absorption and plant health. , the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

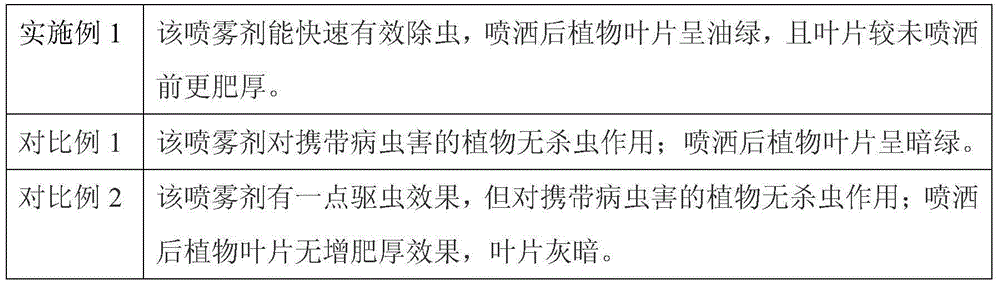

Examples

Embodiment 1

[0022] (1) grinding the silkworm excrement to ultrafine powder, then mixing the ultrafine powder with an ethanol solution with a volume concentration of 40% to a viscous state for granulation, and then spraying a citric acid solution with a volume concentration of 90% on the surface to obtain a masterbatch;

[0023] (2) Heat the masterbatch obtained in step (1) to 50°C at a heating rate of 5°C / h, and keep it warm for 1.5h, then raise the temperature to 180°C at a heating rate of 30°C / h, keep it warm for 30min, and then cool naturally to room temperature, then crush the masterbatch to 20 mesh fine powder;

[0024] (3) Extract the fine powder obtained in step (2) with sherwood oil for 2 hours, and collect the extract to be the silkworm excrement;

[0025] (4) Prepare materials according to the following components by mass percentage: pyrethrin former drug 1%, step (3) gained silkworm excrement extract 10%, alcohol waste mash 50%, green brick powder 5%, charcoal powder 5%, 5% br...

Embodiment 2

[0028] (1) Grinding silkworm excrement to ultrafine powder, then mixing the ultrafine powder with ethanol solution with a volume concentration of 50% to a viscous state for granulation, and then spraying a citric acid solution with a volume concentration of 75% on the surface to obtain master batches;

[0029] (2) Raise the temperature of the masterbatch obtained in step (1) to 45°C at a heating rate of 8°C / h, and keep it warm for 2h, then raise the temperature to 150°C at a heating rate of 35°C / h, keep it warm for 25min, and then cool naturally to At room temperature, crush the masterbatch to 80 mesh fine powder;

[0030] (3) extracting the fine powder obtained in step (2) with petroleum ether for 1 hour, and collecting the extract is silkworm excrement;

[0031] (4) Prepare materials according to the following components by mass percentage: pyrethrin former drug 3%, step (3) gained silkworm excrement extract 9%, alcohol waste mash 60%, blue brick powder 1%, charcoal powder 1...

Embodiment 3

[0034] (1) grinding the silkworm excrement to ultrafine powder, then mixing the ultrafine powder with an ethanol solution with a volume concentration of 30% to a viscous state for granulation, and then spraying a citric acid solution with a volume concentration of 80% on the surface to obtain a masterbatch;

[0035] (2) Raise the temperature of the masterbatch obtained in step (1) to 40°C at a heating rate of 10°C / h, and keep it warm for 1h, then raise the temperature to 200°C at a heating rate of 40°C / h, keep it warm for 20min, and then cool naturally to At room temperature, crush the masterbatch to 60 mesh fine powder;

[0036] (3) Extract the fine powder obtained in step (2) with petroleum ether for 1.5h, and collect the extract to be the silkworm excrement;

[0037] (4) Prepare materials by the following components by mass percentage: pyrethrin former drug 2%, step (3) gained silkworm excrement extract 8%, alcohol waste mash 55%, green brick powder 3%, charcoal powder 7%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com