Explosive cladding structure of aluminum-titanium steel composite board and method for preparing aluminum-titanium steel composite board

A composite structure and composite board technology, applied in chemical instruments and methods, manufacturing tools, welding equipment, etc., can solve problems such as poor bonding strength at both ends, non-fitting, and inconspicuous composite effect of super-long boards, so as to avoid jet flow stacked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

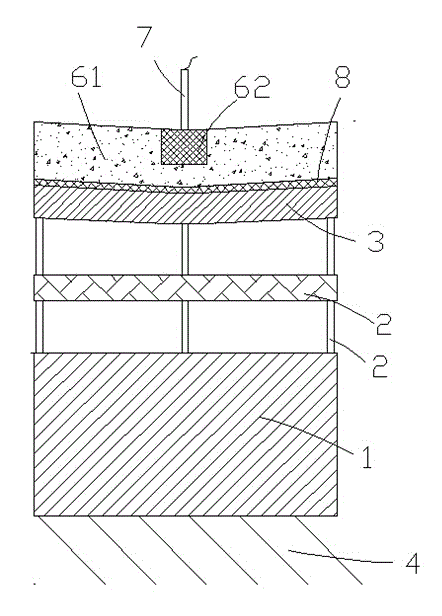

[0027] Figure 1 to Figure 2 Shown is the structural representation of the present invention.

[0028] The reference signs are: steel base plate 1, titanium plate 2, aluminum plate 3, foundation 4, support plate 5, explosive layer 6, main explosive 61, high-velocity charge 62, detonator 7, protective layer 8.

[0029] The aluminum-titanium-steel composite plate explosive composite structure of the present invention includes a steel base plate 1, a titanium plate 2, and an aluminum plate 3, wherein: the steel base plate 1 is placed on the foundation 4, the titanium plate 2 is located above the steel base plate 1, and the aluminum plate 3 is located on the Above the titanium plate 2, between the steel base plate 1 and the titanium plate 2, between the titanium plate 2 and the aluminum plate 3 are separated by a support piece 5, and the upper sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com