Hydrogel composition for gastrointestinal submucosal injection and application of hydrogel composition

A hydrogel and composition technology, which is applied in the field of preparation of composite materials for endoscopic submucosal dissection, can solve problems such as being difficult to meet, submucosal injection materials need to be developed, etc., so as to reduce the difficulty of surgical operation and increase the Thickness, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

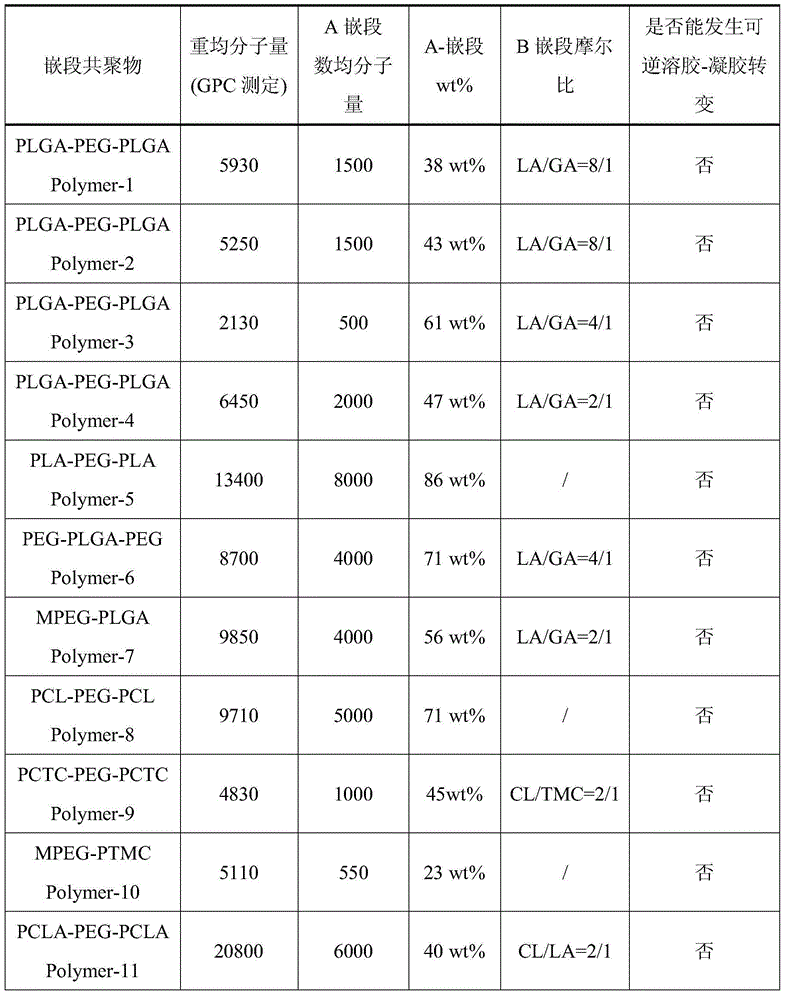

[0075] Add 30g PEG1500 into a 250ml four-neck bottle, heat the oil bath to 140°C under vacuum to melt the PEG, and stir for 2 hours to remove a small amount of water contained in the PEG. Lower the temperature of the oil bath to 85°C, and add 45 g of DL-lactide (LA) and glycolide (GA) at a molar ratio of 8:1 to the four-necked flask under an argon atmosphere, and add 0.1 wt % stannous octoate (containing a small amount of toluene) as a catalyst. The reaction was stirred at 150° C. for 12 hours while maintaining an argon atmosphere. After the reaction was completed, vacuum was applied at 120° C. for 3 hours to remove unreacted monomers and low-boiling components. Pour the crude product from the four-necked bottle into water several times its weight while it is hot, wash at 80°C and wait for the polymer to fully settle, pour off the upper water layer, repeat several times, and then freeze-dry to remove residual water. The yield is about 75wt%. The number average molecular wei...

Embodiment 2

[0077] Take 12.5g PEG5000 and dissolve in 120mL toluene, distill to 50mL to remove the residual water in the polymer. Add 5g of caprolactone (CL) and 0.2wt% stannous octoate as a catalyst, and reflux at 120°C for 24h. Then ether was added to the above solution, and the initial product was obtained by precipitation. The obtained primary product was dissolved in 30 mL of dichloromethane, ether was slowly added to precipitate it, and the residual solvent in the product was removed by vacuuming to obtain a PCL-PEG-PCL triblock copolymer material with a yield of about 80%. The number average molecular weight and weight average molecular weight of the BAB triblock copolymer PCL-PEG-PCL (Polymer-8) measured by gel permeation chromatography (GPC) (using polystyrene as a standard sample) are 8230 and 9710 respectively , Molecular weight distribution coefficient Mw / Mn is 1.18. This copolymer (Polymer-8) can be dissolved in water, but the sol-gel transition cannot occur with the increa...

Embodiment 3

[0079] Add 20g of PEG1000 into a 250ml four-neck bottle, heat the oil bath to 140°C under vacuum to melt the PEG, and stir for 2 hours to remove a small amount of water contained in the PEG. Lower the temperature of the oil bath to 85°C, under an argon atmosphere, add a total of 57 g of DL-lactide (LA) and glycolide (GA) at a molar ratio of 8:1, and add 0.1 wt % stannous octoate (containing a small amount of toluene) as a catalyst. The reaction was stirred at 150° C. for 12 hours while maintaining an argon atmosphere. After the reaction was completed, vacuum was applied at 120° C. for 3 hours to remove unreacted monomers and low-boiling components. Pour the crude product from the four-necked bottle into water several times its weight while it is hot, wash at 80°C and wait for the polymer to fully settle, pour off the upper water layer, repeat several times, and then freeze-dry to remove residual water. The yield is about 85wt%. The number average molecular weight and weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Molecular weight distribution coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com