Zaocys dhumnades oil product and preparation method thereof

A black wind snake, snake oil technology, applied in the direction of pharmaceutical formulations, medical preparations containing active ingredients, peptide/protein components, etc., can solve the problem of shortening the time of high-temperature refining of snake oil, difficult skin absorption, and shortening the cooking time Time and other issues, to achieve the effect of rich raw materials, high transparency, and long product shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

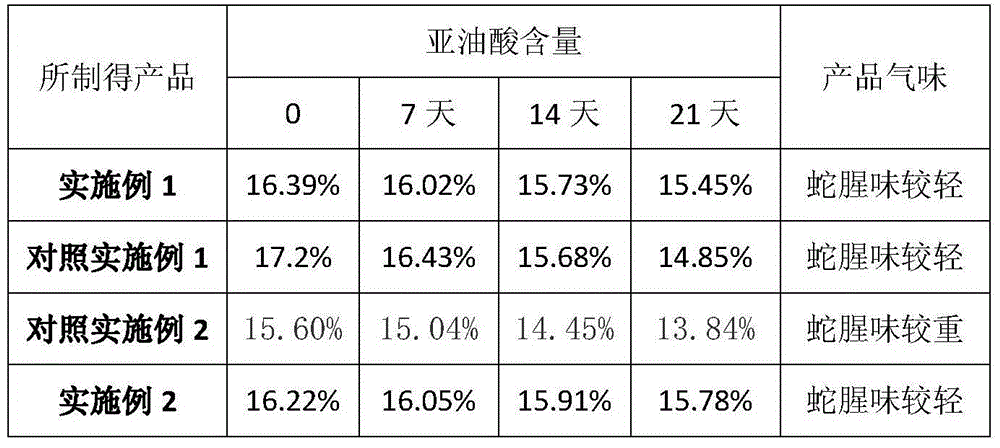

[0041] 100kg of pharmaceutical grade black wind snake is pulverized to 10-20 mesh to obtain snake powder. Add 200 L of acetone to the snake powder, stir and extract at room temperature under nitrogen protection for 90 minutes, filter the extract through a ceramic membrane with a pore size of 0.22 μm, then add 200 L of acetone to the extracted snake powder, and stir and extract at room temperature under nitrogen protection. Extract for 60 minutes, filter through a ceramic membrane with a pore size of 0.22 μm to obtain the extract, combine the two extracts to obtain the acetone filtrate and snake residue. Add 12kg of 0.5mm neutral activated carbon particles to the acetone filtrate, decolorize at room temperature for 20-30 minutes under the protection of nitrogen, filter once with a ceramic membrane, concentrate under reduced pressure at 40°C to remove acetone, obtain an oil, and extract once with twice the volume of ethanol , to obtain ethanol extract, concentrated under reduced...

Embodiment 1

[0044] Take 100 kg of pharmaceutical grade black wind snake, crush it until it passes through a 10-mesh sieve, and get snake powder; add the above snake powder to 400 kg of acetone, extract for 150 minutes, recover acetone to obtain crude snake oil, add 3% neutral activated carbon, and heat to 50 ° C Decolorize for 20 minutes, filter through 500 mesh to remove activated carbon, and obtain refined black wind snake oil. The content of linoleic acid in the prepared snake oil product detected by gas chromatography is 17.2%.

Embodiment 2

[0046] According to the method provided by CN103468390A, the specific steps are as follows: extract the adipose tissue of the snake, wash it several times, and remove impurities such as snake skin and fibers mixed in; heat and refine the extracted fat, and stop heating after 10 minutes to obtain the extracted fat. liquid, and filter it with gauze once while it is hot within 1 min, until the filtrate is invisible to the naked eye to obtain the filtrate and filter residue, and the obtained filtrate is the main liquid of snake oil; press the above filter residue for 5 minutes until no oil seeps out to obtain the squeeze liquid; The above-mentioned squeezed liquid is filtered once, and the obtained filtrate is the snake oil contained in the filter residue; the above-mentioned obtained filtrate is combined and passed to obtain the snake oil crude product; the snake oil crude product is extracted 3 times with an organic solvent, and the quality of the organic solvent is snake oil 1 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com