Modification method of lithium-rich manganese-based cathode materials

A lithium-rich manganese-based, cathode material technology, which is applied in battery electrodes, electrical components, circuits, etc., can solve problems such as large-scale production that is not suitable for industrialization, and is conducive to the stability of the crystal structure of the material, the method is simple, and the electricity is improved. Effects of chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for modifying the lithium-rich manganese-based cathode material of the present invention, comprising the following steps:

[0027] (1) Weigh aluminum fluoride (AlF 3 )0.2793g, weigh the precursor (Mn 0.675 Ni 0.1625 co 0.1625 )(OH) 2 10.0000g, weigh lithium carbonate (Li 2 CO 3 ) 6.4502g, the three are fully mixed uniformly; wherein the aluminum element content in the doped modified metal fluoride salt is 3mol% of the metal element content contained in the precursor;

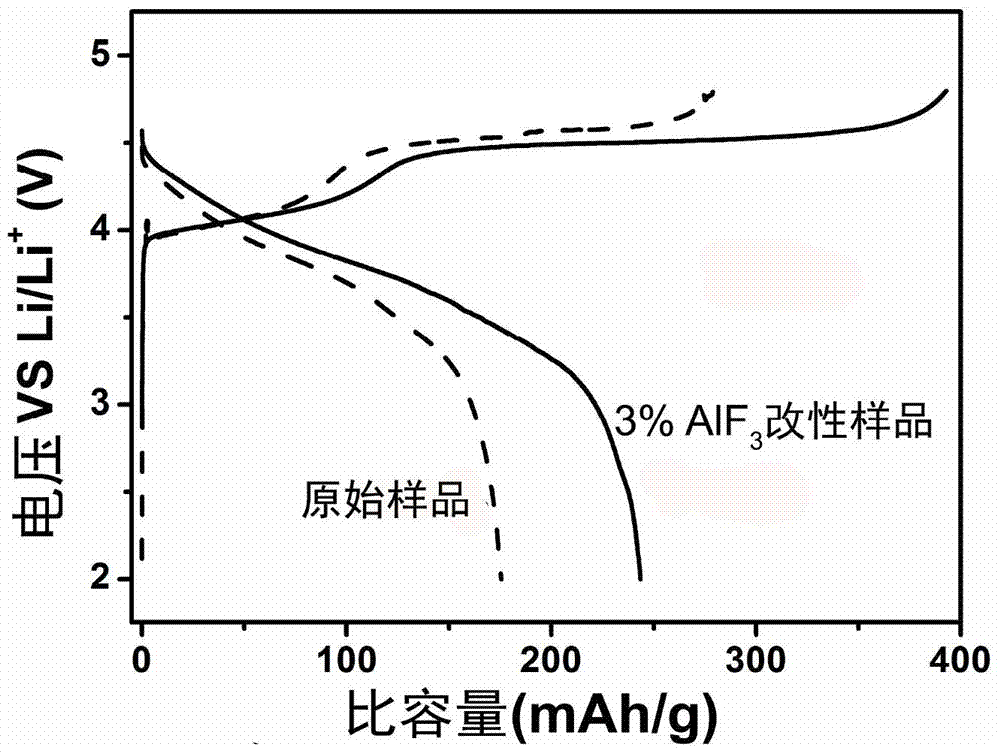

[0028] (2) Sinter the above mixed material at a sintering temperature of 970°C for 15h at a heating rate of 10°C / min, and then cool to room temperature with the furnace to obtain AlF 3 Modified lithium-rich manganese-based cathode materials (Li 1.2 mn 0.54 Ni 0.13 co 0.13 o2 ).

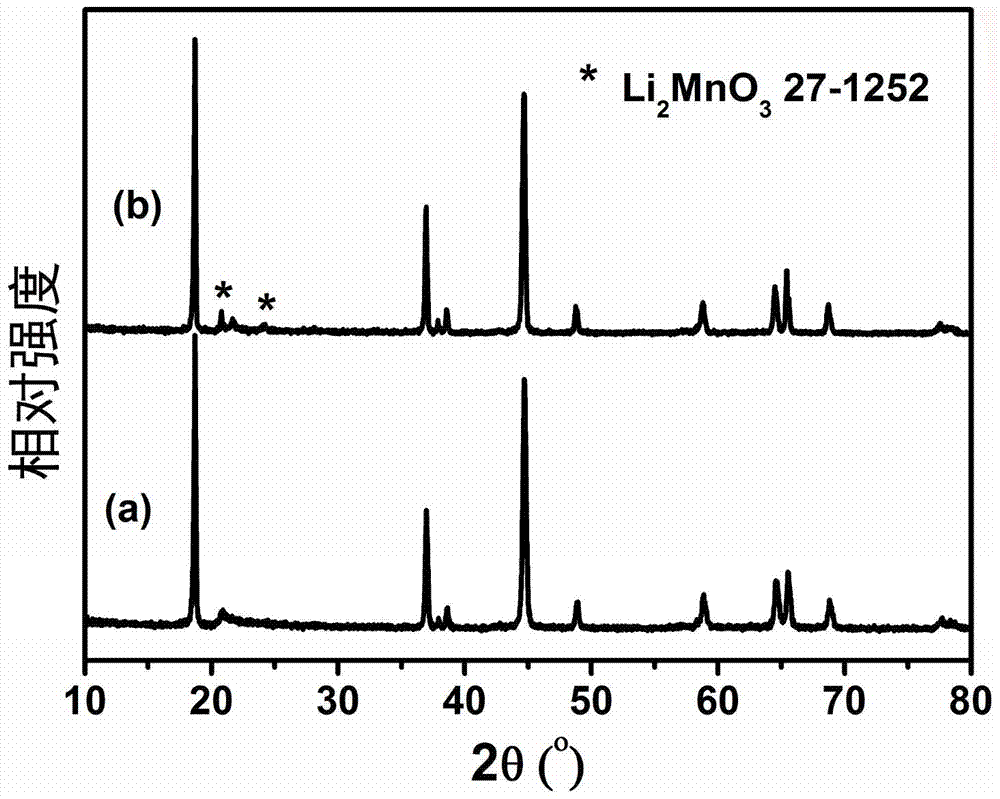

[0029] From the above-mentioned AlF of this embodiment 3 XRD patterns of modified lithium-rich manganese-based cathode materials ( figure 1 ) shows that AlF 3 The addition of makes the lithium-rich phase di...

Embodiment 2

[0032] A method for modifying the lithium-rich manganese-based cathode material of the present invention, comprising the following steps:

[0033] (1) Weigh zirconium fluoride (ZrF 4 )0.9268g, weigh the precursor (Mn 0.675 Ni 0.1625 co 0.1625 )(OH) 2 10.0000g, weigh lithium carbonate (Li 2 CO 3 ) 6.4502g, the three are fully mixed uniformly; wherein the zirconium element content in the doped modified metal fluoride salt is 5mol% of the metal element content contained in the precursor;

[0034] (2) Sinter the above mixed material at a sintering temperature of 850°C for 48h at a heating rate of 10°C / min, and then cool to room temperature with the furnace to obtain ZrF 4 Modified lithium-rich manganese-based cathode materials (Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 ).

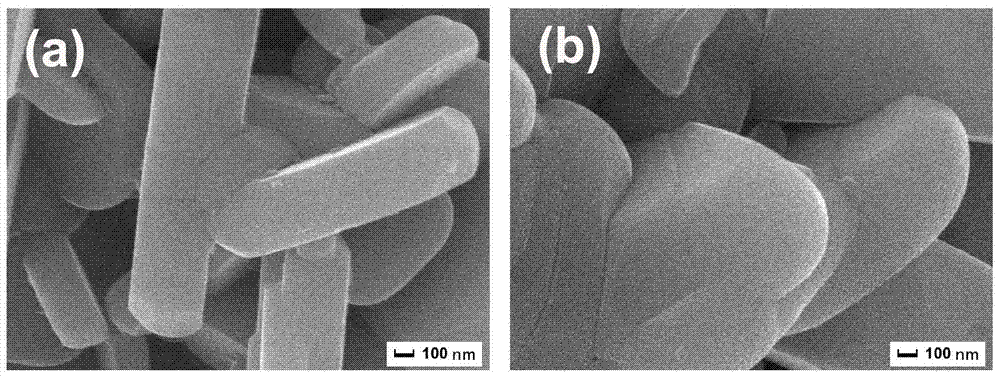

[0035] The ZrF that is made by this embodiment 4 The TEM spectrum of modified lithium-rich manganese-based cathode material (see Figure 5 ) It can be seen that the above-mentioned modification process c...

Embodiment 3

[0037] A method for modifying the lithium-rich manganese-based cathode material of the present invention, comprising the following steps:

[0038] (1) Weigh ammonium fluorotitanate (N 2 h 8 TiF 6 ) 1.7081g, weigh the precursor (Mn 0.75 Ni 0.25 )CO 3 10.0000g, weigh lithium carbonate (Li 2 CO 3 ) 5.0212g, the three are fully mixed uniformly; wherein the content of titanium element in the doped modified metal fluoride salt is 10mol% of the content of the metal element contained in the precursor;

[0039] (2) Sinter the above-mentioned uniformly mixed mixture at a sintering temperature of 1000°C for 24 hours, with a heating rate of 10°C / min, and then cool to room temperature with the furnace to obtain ammonium fluorotitanate-modified lithium-rich manganese-based positive electrode material (Li 1.2 mn 0.6 Ni 0.2 o 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com