Liquid cooling heat dissipation device and liquid cooling heat dissipation temperature control method

A technology of liquid-cooled heat dissipation and liquid-cooled head, which is applied in the direction of temperature control, instrumentation, and electrical digital data processing by using electric methods, and can solve the problem of reducing the operating power of fans and pumps, the inability to adjust the operating power of fans and pumps, and heat dissipation Insufficient heat dissipation efficiency and other problems, to avoid the effect of ineffective heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

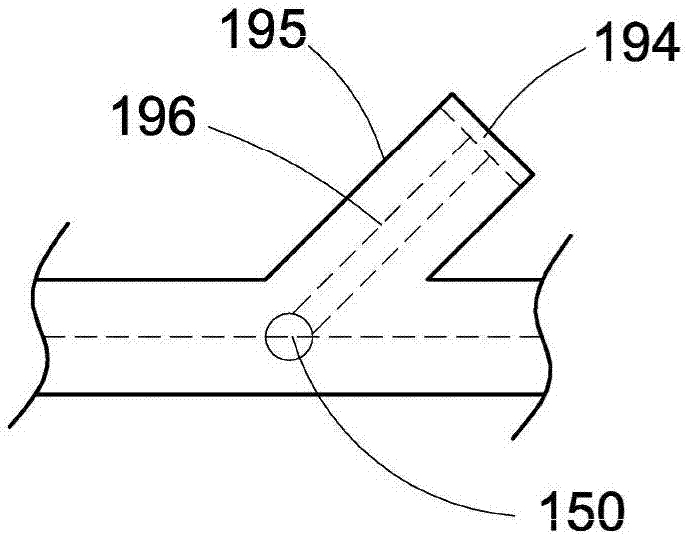

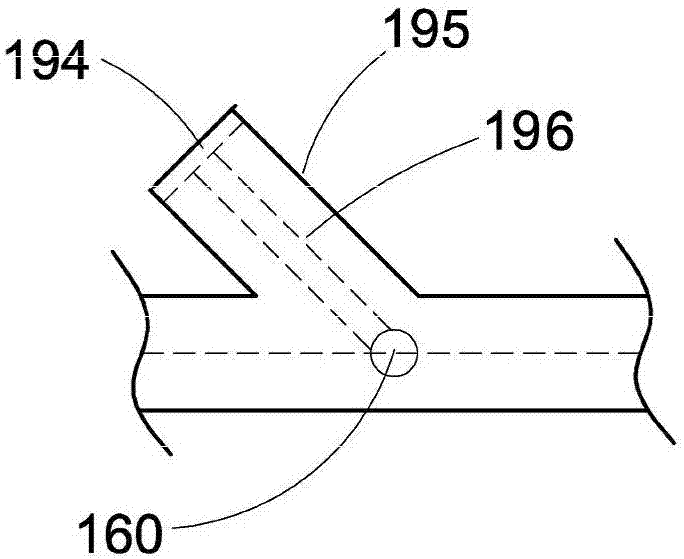

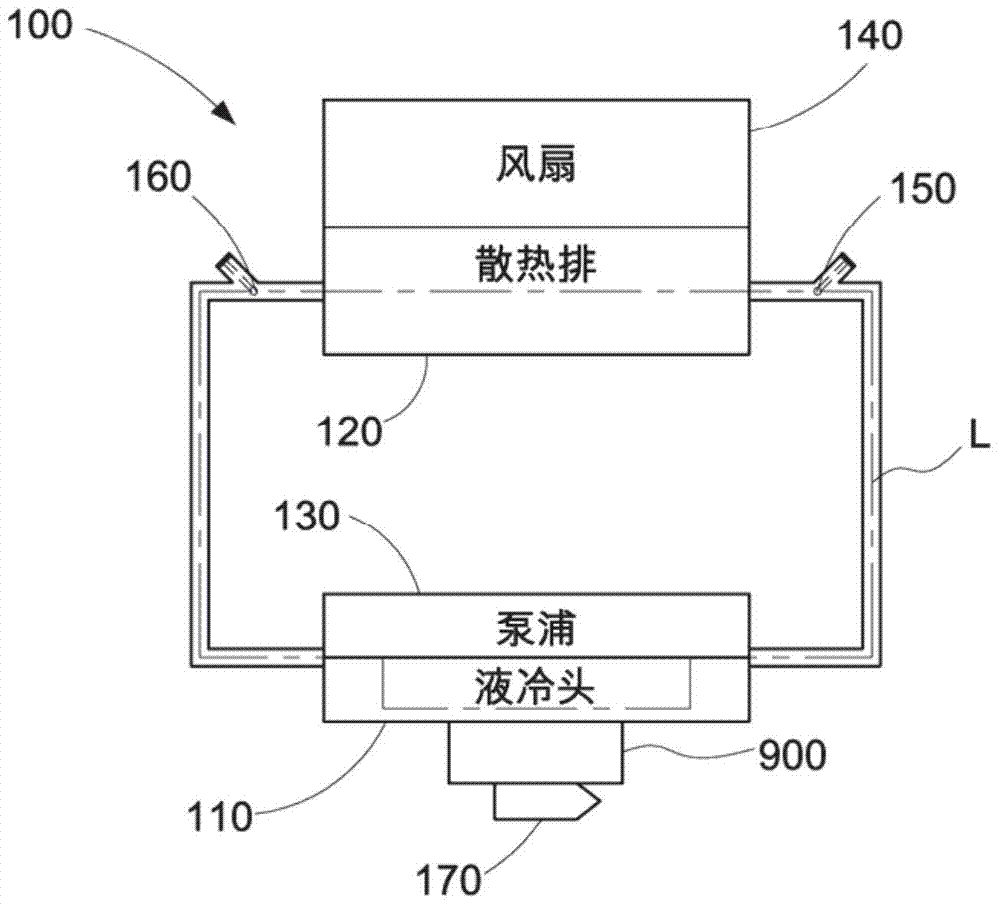

[0023] see figure 1 , figure 2 , image 3 and Figure 4 As shown, a liquid-cooled heat dissipation device 100 disclosed in an embodiment of the present invention is used for pumping a cooling liquid to cool a heat source 900 . The aforementioned heat source 900 includes but is not limited to a high-power integrated circuit chip (such as a central processing unit or a graphics chip). The liquid cooling heat dissipation device 100 includes a liquid cooling head 110, a radiator 120, a pump 130, at least one fan 140, a liquid inlet temperature device 150, a liquid outlet temperature device 160, a heat source temperature sensing device 170 and A control unit 180 .

[0024] Such as figure 1 As shown, the liquid cooling head 110 is usually a metal block or other blocks with thermal conductivity to conduct heat quickly. The liquid cooling head 110 is used to contact the heat source 900 to absorb the heat generated by the heat source 900 . The liquid cooling head 110 has at lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com