Black matrix, manufacture method of black matrix and liquid crystal panel with black matrix

A technology of black matrix and production method, which is applied in the field of liquid crystal panels, can solve the problems of gel, black matrix impedance reduction, easy agglomeration, etc., achieve high optical density, increase optical density, and increase the effect of impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

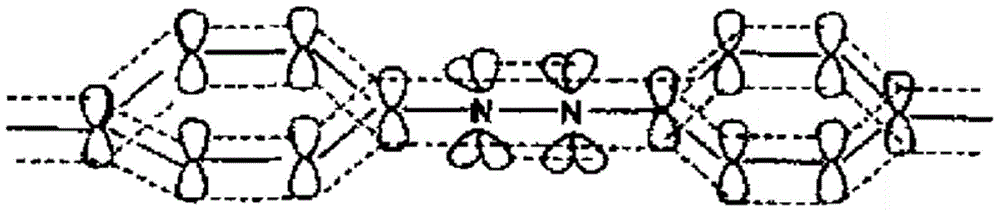

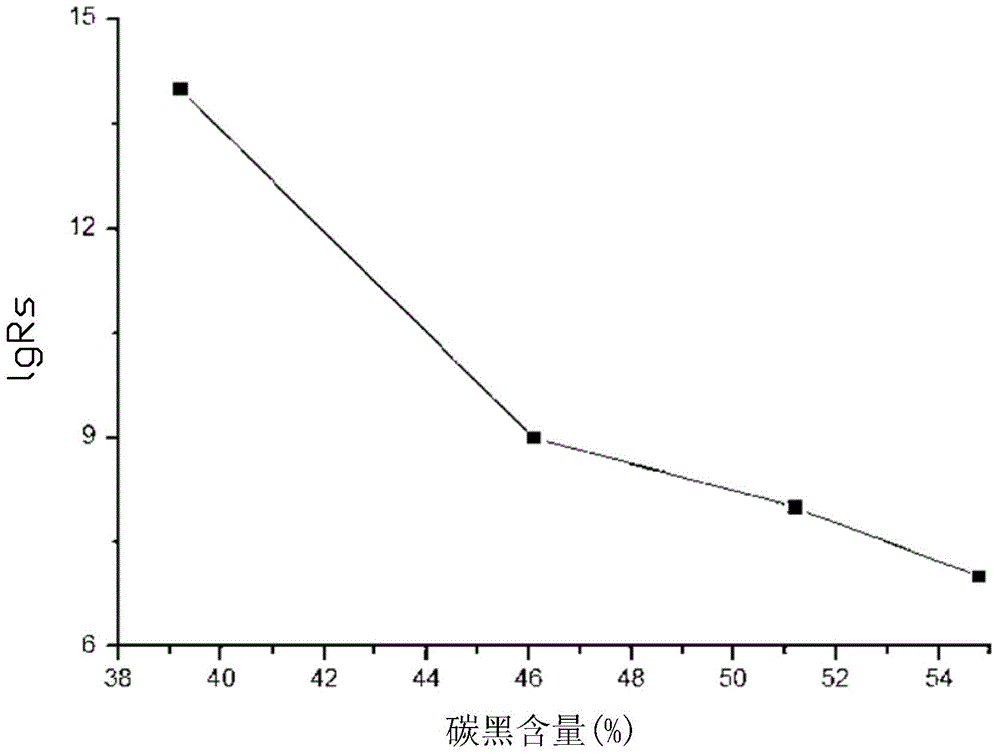

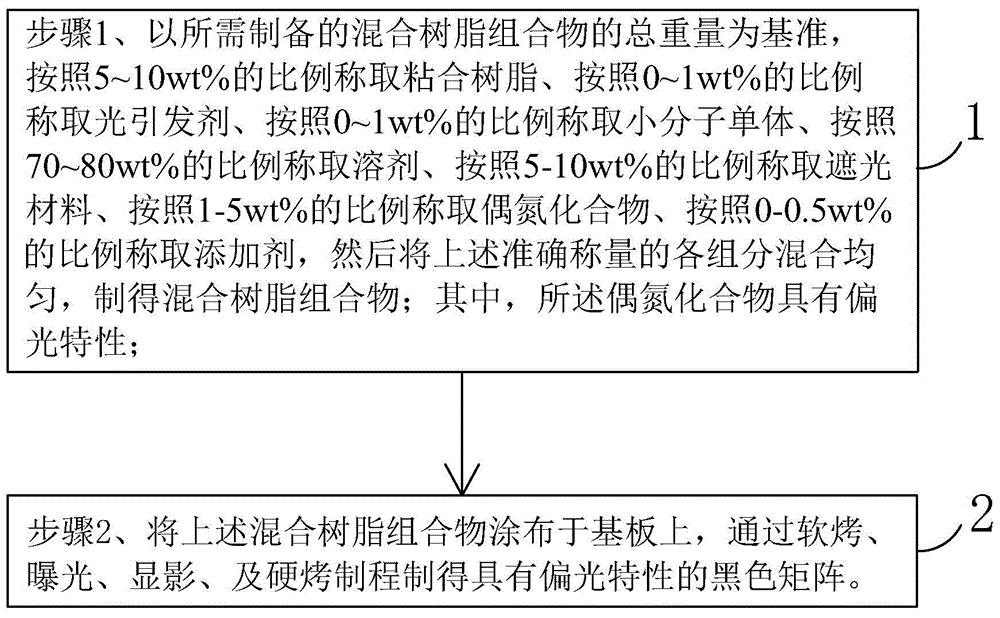

[0035] The present invention firstly provides a black matrix, which is obtained by coating a mixed resin composition on a substrate and patterning it by photolithography after drying, wherein the mixed resin composition includes an adhesive resin (Polymer) , a photoinitiator (Photo Initiator), a small molecule monomer (Monomer), a solvent (Solvent), a light-shielding material, an azo compound, and an additive, and the azo compound has polarizing properties. The adhesive resin can form a film layer and support cross-linking reaction, the photoinitiator can quickly form free radicals under light, the small molecule monomer can polymerize functional groups, and the solvent can adjust coating performance. The light-shielding material can play a li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com