Radiator for semiconductor refrigerator

A heat sink and semiconductor technology, applied in the field of heat transfer, can solve the problems of heat sink with obvious thermal resistance, limited heat dissipation capacity, and low heat dissipation efficiency, and achieve good heat dissipation effect, high heat dissipation efficiency, and improved heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing.

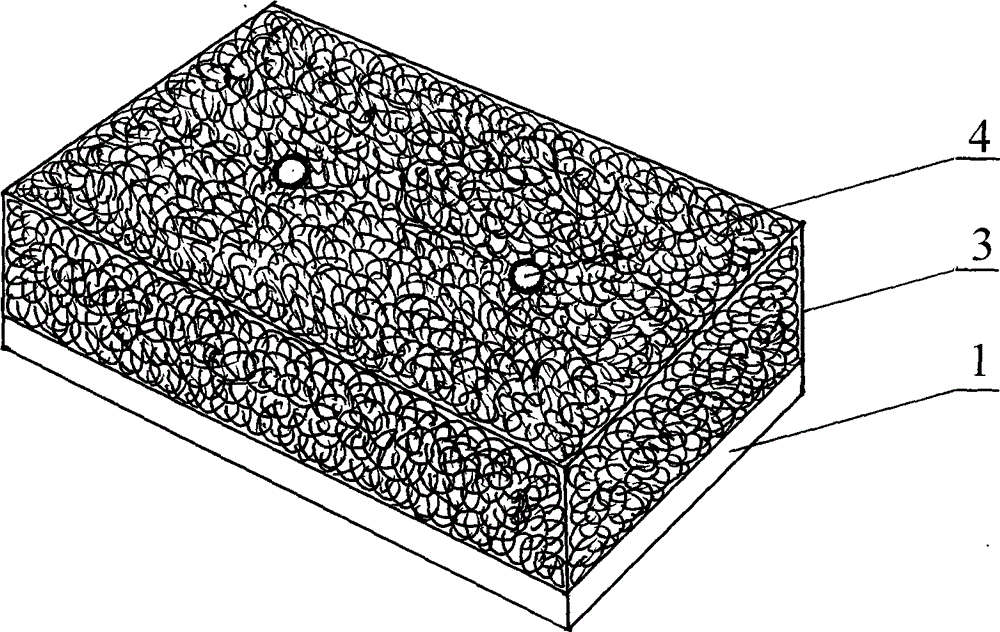

[0009] Such as figure 1 As shown, the foamed aluminum (3) on the radiator is a cubic porous aluminum foam metal material, and the plane size of the foamed aluminum (3) is consistent with the plane size of the vapor chamber (1); the vapor chamber (1) and the foam The aluminum (3) is integrated by welding; the radiator is provided with fixing holes (4).

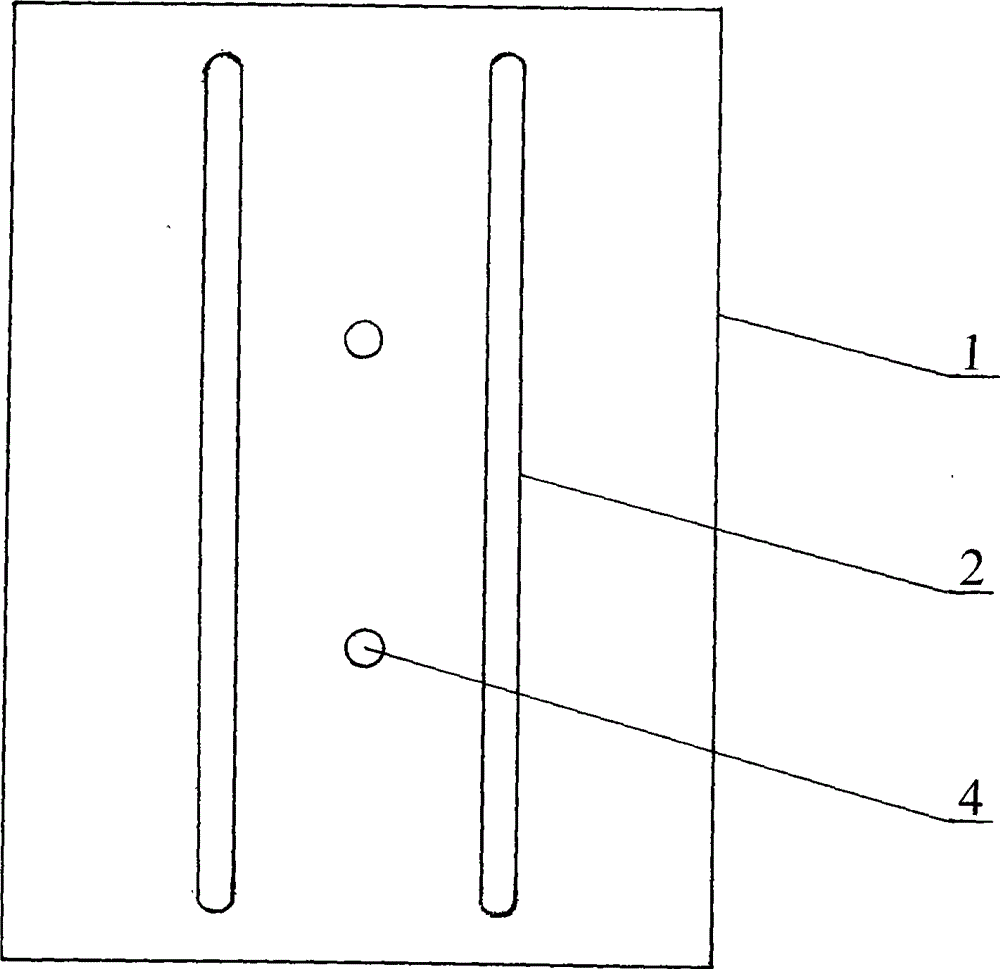

[0010] Such as figure 2 As shown, the temperature chamber (1) is a rectangular aluminum plate; the heat pipe (2) is arranged in the bottom groove of the temperature chamber (1).

[0011] The working principle of the present invention: when using the radiator for semiconductor refrigerators provided by the present invention, in order to reduce the thermal resistance, apply an appropriate amount of heat-conducting silicon grease on the heating surface of the semiconductor chip, and directly place the central position of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com