Profiled steel sheet-UHP (ultra high performance) fiber reinforced concrete composite bridge deck

A profiled steel plate, fiber reinforced technology, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of increasing the stiffness of composite bridge decks, fatigue damage interface bonding, reducing stress amplitude, etc., to improve the structural bearing capacity, Faster builds and replacements, fewer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the drawings and embodiments.

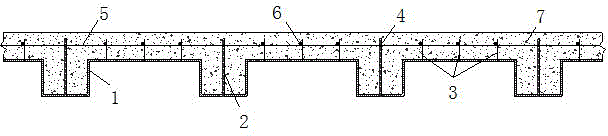

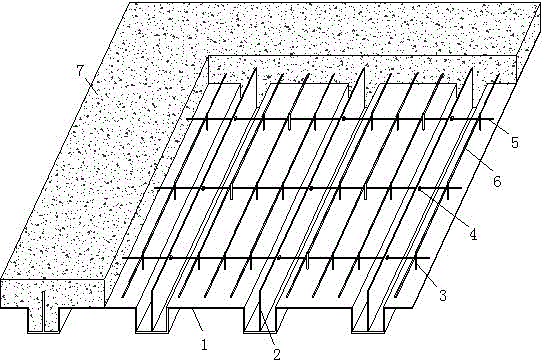

[0017] Such as figure 1 with figure 2 As shown, it includes concave profiled steel plate 1, perforated steel plate 2, vertical studs 3, transverse steel bars 5, longitudinal steel bars 6, and ultra-high performance fiber reinforced concrete 7. Set the perforated steel plate 2 in the recess of the concave profiled steel plate 1, and set the vertical stud 3 in the convex place. The transverse steel bar 5 is penetrated in the perforated steel plate connection hole 4 and welded above the vertical stud 3, and the transverse steel 5 Vertical steel bars 6 are arranged in the vertical direction. The longitudinal steel bars 6 are located above the horizontal steel bars 5 and are fixed to the connection points of the horizontal steel bars 5 and the vertical studs 3. The ultra-high performance fiber reinforced concrete is poured on the concave profiled steel plate 1 Inside, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com