Method for producing biogas from fruit and vegetable wastes

A technology for fruits, vegetables and products, applied in the direction of waste fuel, fermentation, etc., can solve the problems of not obvious reduction effect, large land occupation, and large amount of production, so as to realize energy utilization, increase processing speed, and stable and reliable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

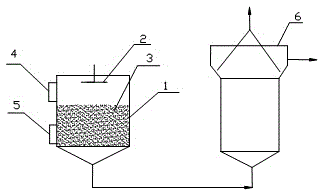

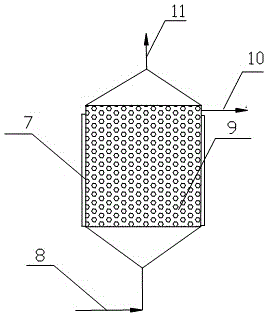

Image

Examples

Embodiment Construction

[0019] This embodiment will be further described below.

[0020] A method for producing biogas from fruit and vegetable waste is characterized in that it includes the following steps: Step 1: raw material pretreatment.

[0021] Use a pulverizer to cut fruit and vegetable wastes such as fruit peels and leaves into 2-3cm, and then put them into a 500 r / min ball mill for grinding for 15 minutes. Through the collision and friction of the grinding media, the fruits and vegetables are crushed and mixed, and can destroy them. The structure of refractory cellulose, the release of bound water in raw materials and intracellular water and intracellular substances of plant cells, plays an important role in the subsequent solid-liquid separation and substrate degradation, and the pasty outflow after treatment stored in storage tanks.

[0022] Step 2: solid-liquid separation coupling.

[0023] The pasty effluent is separated from the solid and liquid by a plate and frame filter press ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com