Polyurethane composition, polyurethane foam as well as manufacture method thereof and fridge

A technique of polyurethane foam and its manufacturing method, which is applied in the field of polyurethane foam and its manufacture, and polyurethane composition, which can solve the problems of reducing refrigerator liner and refrigerator production efficiency, uneven thickness of foam alloy layer, increasing refrigerator cost, etc., and achieve fluidity And good adhesion, good fluidity, the effect of improving the bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

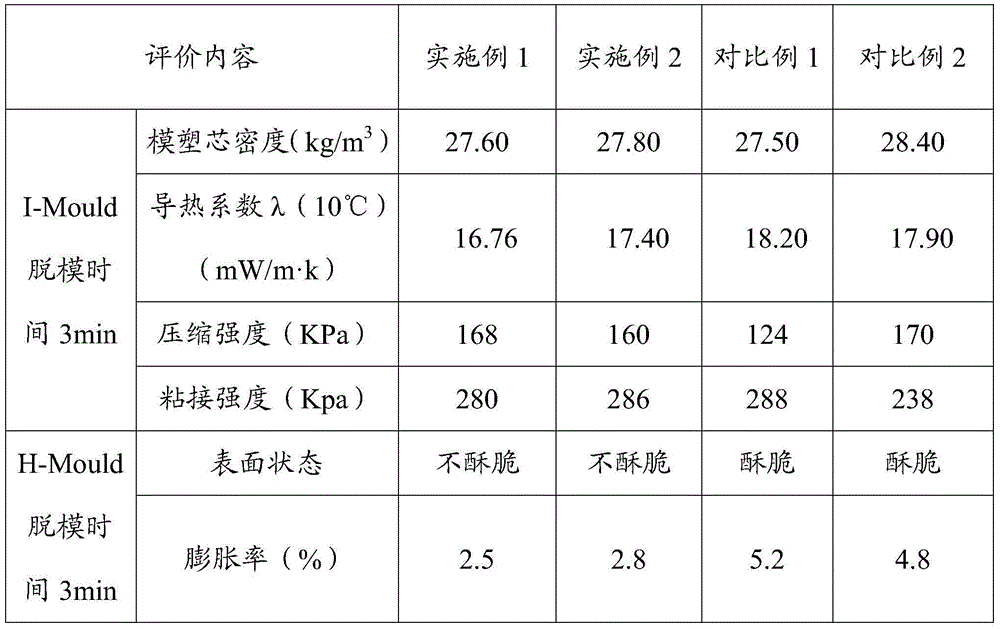

[0041] According to the preparation method provided by the embodiments of the present invention, the raw material used is the polyurethane composition described above, and the polyurethane foam prepared by this method has a low density, less than 28.5kg / m 3 , but has strong adhesion, and after foaming or high and low temperature impact, the foam and the inner tank will not be separated; in addition, the thermal conductivity of polyurethane foam prepared by this method is low, less than 17.5mW / m·k , High compressive strength, the minimum compressive strength is greater than 150Kpa.

[0042] It is worth noting that the polyurethane foam and its preparation method provided by the present invention use low vapor phase thermal conductivity, low GWP, and zero ODP foaming agent, which not only meets the energy-saving requirements, but also is environmentally friendly and green.

[0043] According to an embodiment of the fifth aspect of the present invention, the manufacturing method ...

Embodiment 1

[0047] Raw material formula: the sorbitol polyether polyol of 40 weight parts, the complex polyether polyol of 21.4 weight parts, the diphenylmethanediamine polyether polyol of 15 weight parts, the glycerine polyether polyol of 5 weight parts, 10 The aromatic polyester polyol of weight part, 3 parts of composite cross-linking agents (glycerol and ethylenediamine weight ratio 1:1), the foaming catalyst (PC-12) of 0.5 weight part, the gel catalyst (PC-12) of 1.8 weight part PC-8), 0.5 parts by weight of polymerization catalyst (TMR-2), 2.0 parts by weight of silicon foam stabilizer, 1.6 parts by weight of water, 38 parts by weight of trans-1-chloro-3,3,3- Trifluoropropene and 133.9 parts by weight of PM2010 (isocyanate index: 0.97) of Yantai Wanhua.

[0048] Preparation method 1: Premix the components in the above raw material formula except for isocyanate in a stirring pressure tank. The isocyanate in the material working tank is injected into the I-Mould mold (the mold size i...

Embodiment 2

[0051] Raw material formula: the sorbitol polyether polyol of 40 weight parts, the complex polyether polyol of 21.4 weight parts, the diphenylmethanediamine polyether polyol of 15 weight parts, the glycerine polyether polyol of 5 weight parts, 10 The aromatic polyester polyol of weight part, 3 parts of composite crosslinking agents (glycerol and ethylenediamine weight ratio 1:1), the foaming catalyst (PC-12) of 0.6 weight part, the gel catalyst (PC-12) of 1.5 weight part PC-8), 0.5 parts by weight of polymerization catalyst (TMR-2), 2.0 parts by weight of silicon foam stabilizer, 1.8 parts by weight of water, 8 parts by weight of trans-1-chloro-3,3,3- Trifluoropropene, 12 parts by weight of cyclopentane, 5 parts by weight of pentafluoropropane (HFC-245fa), and 137.5 parts by weight of PM2010 (isocyanate index: 1.10) from Yantai Wanhua.

[0052] Preparation method 1: with embodiment 1;

[0053] Preparation method 2: same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com