Straw pretreatment method for hemicellulose production

A technology of straw pretreatment and hemicellulose is applied in the field of extraction of active ingredients in straw, which can solve the problems of inability to dissolve and fall off lignin, incapability of deacetylation reaction of hemicellulose, avoid dark color and facilitate clean production. , the effect of reducing the acetate concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 10g of bagasse, put it in a 250ml Erlenmeyer flask, add 80mL of pretreatment solution, the pretreatment solution is 10g / L NaOH aqueous solution, soak the bagasse and immediately pour out 50mL of the liquid, the remaining solid-liquid ratio is 1:3, put Heat to 100°C in a sterilizing pot, heat-preserve and cook for 10 minutes, take out the triangular flask (pH of the mixture after cooking in the triangular flask=11), press out the liquid, wash the residue once with water, combine the two filtrates, a total of 50mL, namely For the pretreatment of waste water, its pH=10.5, and the concentration of acetate in it was determined to be 0.19%.

Embodiment 2

[0026] The unpretreated bagasse 100g (the same batch of raw materials as in Example 1) and all the remaining solids after the pretreatment in Example 1 were used to extract hemicellulose by alkaline method respectively.

[0027] The extraction conditions are: solid-to-liquid ratio 1:5, the lye used for extraction is NaOH aqueous solution with a concentration of 8% (w / v), the extraction time is 12 hours, and the temperature is room temperature.

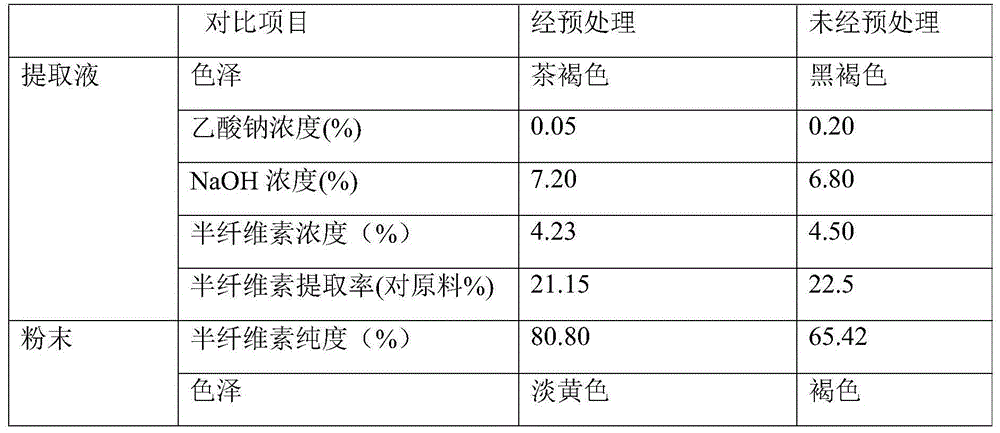

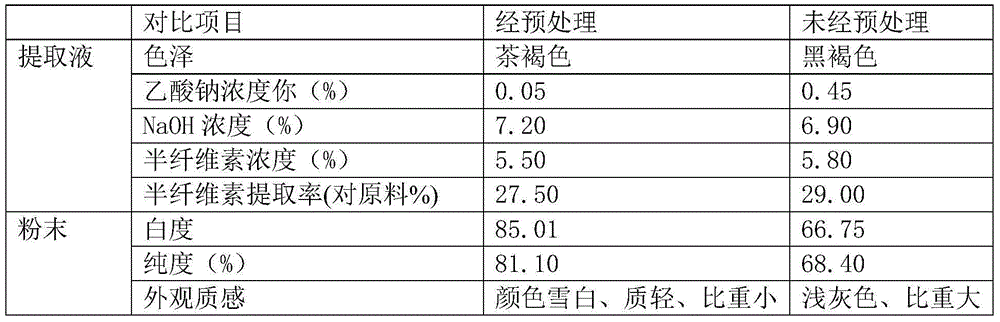

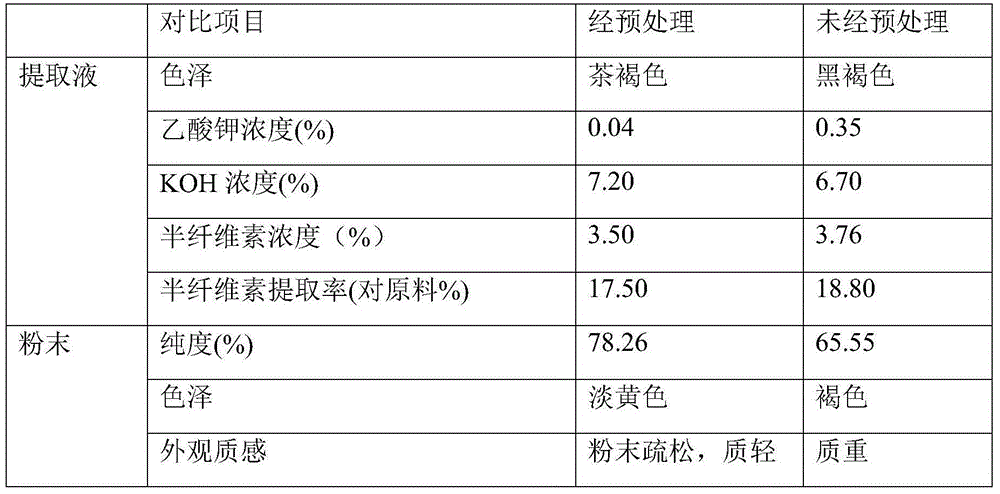

[0028]Carry out acetate, NaOH concentration, color and luster to the obtained hemicellulose extracting liquid then and measure contrast, and with the 95% (v / v) ethanol alcohol precipitation that is equivalent to 3 times of extracting liquid volume, 75% ethanol washing hemicellulose, Finally, the color and purity of the dried hemicellulose powder were compared, and the results are shown in Table 1.

[0029] Table 1: whether to adopt the method pretreatment of the present invention to the impact of bagasse extraction hemicellulose result...

Embodiment 3

[0033] Take 100g of corn cobs, crush them (thickness is 0.8-5cm), add 400mL of pretreatment solvent, the pretreatment solvent is 6g / L NaOH aqueous solution, put it in a sterilizer and raise the temperature to 100°C, keep it warm for 20min, and take out the triangular corncob. bottle (pH=10 of the mixture after cooking in the Erlenmeyer flask), press out the liquid, and measure the acetate concentration in the filtrate to be 0.45%. The filter residue was washed once with hot water, squeezed and dried in the air for hemicellulose extraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com