A method of treating sludge using solar pyrolysis carbonization technology

A technical treatment and solar thermal technology, which is applied in the field of sludge treatment using solar pyrolysis carbonization technology, can solve the problems of unrealized sludge reduction, energy consumption, high equipment investment and operation costs, and moisture content that cannot meet the requirements. It is not easy to migrate and be absorbed by plants, and realize the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

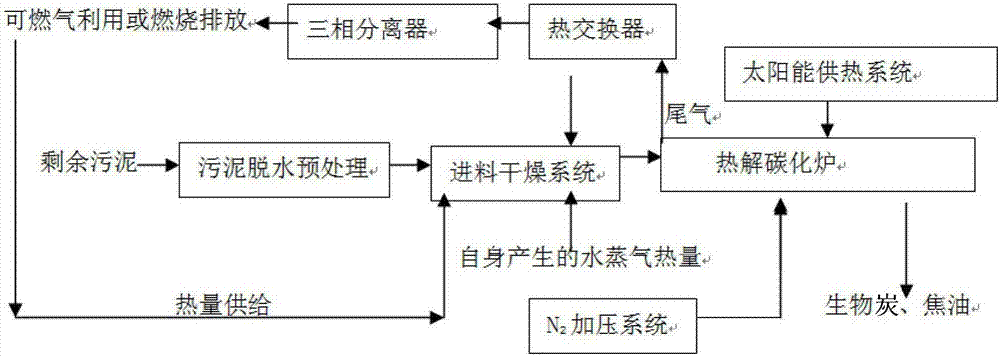

[0048] Example 1 Surplus sludge with a water content of 99.7% in the sewage treatment plant of Yangdong Economic Development Zone

[0049] Such as figure 2 As shown in , take 40kg of excess sludge with a moisture content of 99.7%, and after dehydration treatment by the sludge dehydration treatment facility, the dehydrated mud cake will directly enter the drying system. The drying time is 130 minutes. The heat source of the drying system is heat The heat generated by the combustion of combustible gas in the tail gas of the decarbonization furnace and the heat of the water vapor generated by itself;

[0050] The dried sludge enters the pyrolysis carbonization furnace (the pyrolysis carbonization furnace sold on the market can be used), the aspirator of the pyrolysis carbonization furnace system is turned on, and when the pressure in the furnace drops to 0MPa, the solar heating system and the N 2 The pressurized system, in which the solar heating system adopts the traditional s...

Embodiment 2

[0053] Example 2 Surplus sludge with a water content of 99.7% in the sewage treatment plant of Yangdong Economic Development Zone

[0054] Such as image 3 As shown, 40kg of excess sludge with a moisture content of 99.7% is drawn directly into the drying system, and the drying time is 130 minutes. the heat of the water vapor produced;

[0055] The dried sludge enters the pyrolysis and carbonization furnace, and the aspirator of the pyrolysis and carbonization furnace system is turned on. When the pressure in the furnace drops to 0MPa, the solar heating system and the N 2 The pressurized system, in which the solar heating system uses the traditional solar energy to convert heat energy, then converts heat energy into electrical energy, and then converts electrical energy into heat energy to supply heat. The temperature is controlled at 330 °C and the pressure is controlled at 12 MPa. A series of reactions including vaporization, pyrolysis, dehydrogenation, thermal shrinkage an...

Embodiment 3

[0058] Example 3 Surplus sludge with a water content of 99.7% in the sewage treatment plant of Yangdong Economic Development Zone

[0059] Such as figure 2 As shown in , extract 40kg of excess sludge with a water content of 99.7%, and pass through the original sludge dehydration treatment system to obtain a mud cake with a water content of 65%. The dehydrated mud cake is put into the drying system, and the drying time is 120 minutes. The heat source of the system is the heat generated by the waste gas of the pyrolysis carbonization furnace and the combustible gas combustion in the tail gas and the heat of the water vapor generated by itself;

[0060] Put the dried sludge into the pyrolysis carbonization furnace, turn on the aspirator of the pyrolysis carbonization furnace system, and when the pressure in the furnace drops to 0MPa, turn on the solar heating system and the N 2 The pressurized system, in which the solar heating system uses traditional solar energy to convert he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com