Sulfuric chloride separation and purification technique

A sulfuryl chloride and process technology, which is applied in the field of separation and purification of sulfuryl chloride in the reaction waste liquid of the production process of trifluoroacetyl chloride, can solve the problems of large waste acid discharge in the production cost of trifluoroacetyl chloride, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

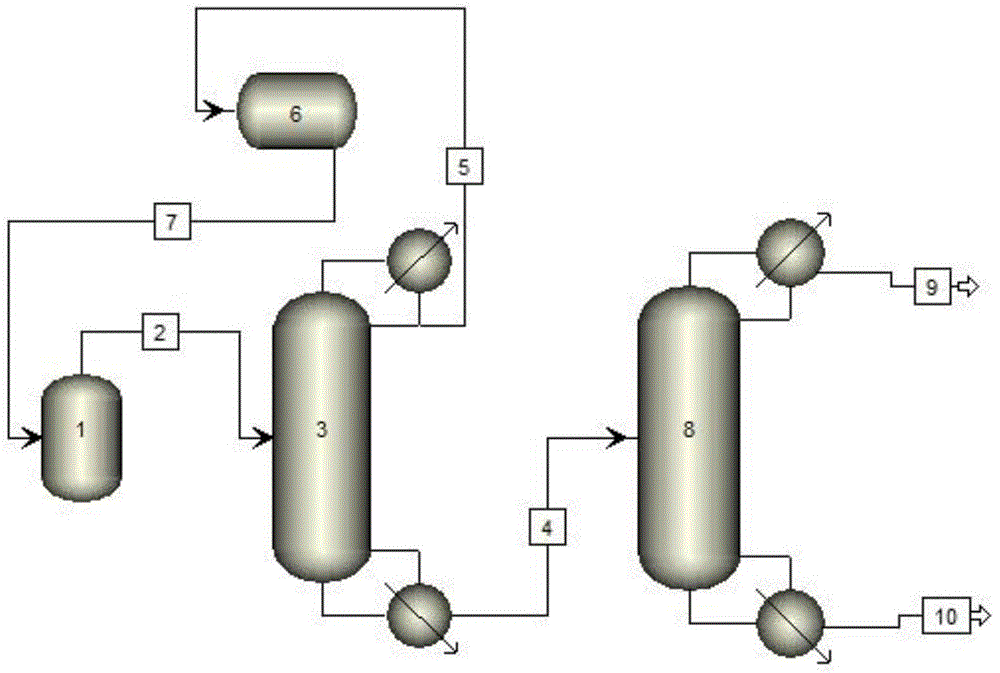

[0022] According to the drawings in the manual figure 1 Sulfuryl chloride is separated and purified by double-tower continuous atmospheric distillation, and the production reaction waste liquid (2) comes from the trifluoroacetyl chloride production line, in which the mass contents of sulfuryl chloride, trifluorotrichloroethane, sulfur trioxide and pyrosulfuryl chloride are respectively 80%, 5%, 12% and 3%. Both the primary rectification tower (3) and the secondary rectification tower (8) are filled with glass spring packing. Pass the production reaction waste liquid (2) into the primary rectification tower (3) for rectification. The reflux ratio is 5, the number of theoretical plates is 10, and the stream (5) which is basically trifluorotrichloroethane and sulfur trioxide is obtained from the top of the tower, and is circulated to the reactor (1) to continue the reaction. A stream (4) mainly of sulfuryl chloride is obtained, wherein the mass content of sulfuryl chloride is a...

Embodiment 2

[0024] Other conditions are the same as in Example 1, but the production reaction waste liquid (2) is changed, wherein the mass contents of sulfuryl chloride, trifluorotrichloroethane, sulfur trioxide and pyrothionyl chloride are 85%, 7%, 4% and 4% respectively , collected from the top of the secondary distillation column (8), with a purity of 98.2% and a recovery rate of 80.3%.

Embodiment 3

[0026] Other conditions are the same as in Example 1, the reflux ratio of the primary rectification tower (3) is changed to 5, the purity of the high-purity sulfuryl chloride finished product (9) obtained after the secondary rectification is 99.1%, and the recovery rate is 75.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com