Traditional Chinese medicinal preparation for treating acute upper respiratory infection and preparation method of traditional Chinese medicinal preparation

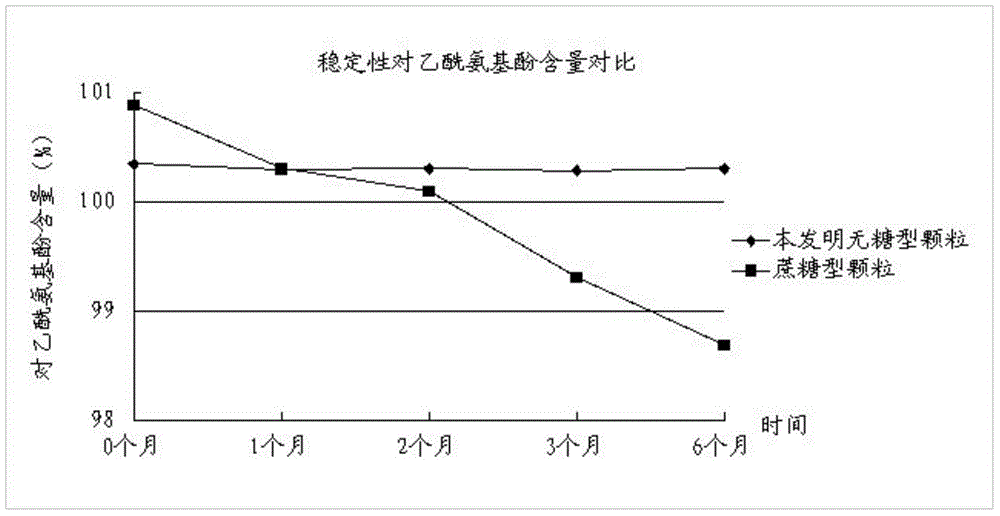

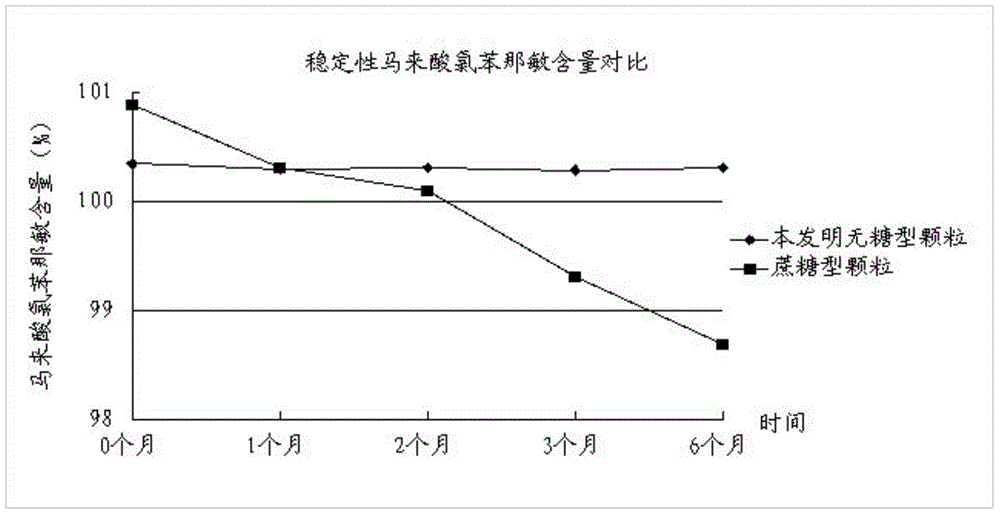

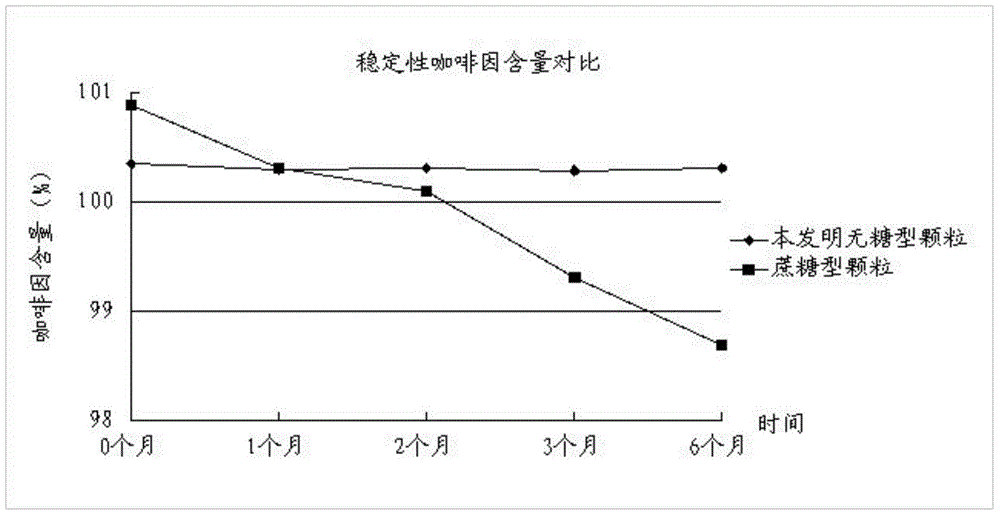

A technology for the upper respiratory tract and traditional Chinese medicine preparations, which is applied in the direction of medical formulas, respiratory diseases, and medical preparations containing active ingredients, etc. It can solve the problems of inappropriate use of granules, reduced drug efficacy, and drug restrictions, and achieve the reduction of the dosage of excipients , Guaranteed clinical efficacy and high drug stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Take 100g of honeysuckle, 430g of mandarin orange, 500g of Sanchaku, 330g of wild chrysanthemum, 290g of Nanlan root, and 860g of plum, add water to decoct, the mass ratio of the weight of water to the components weighed is 10:1, decoct Distilled for 1 to 2 hours, distilled, collected distilled liquid, added 30g β-cyclodextrin to the distilled liquid, mixed to make it completely clathrated, filtered the mixed liquid, dried, and dried at a temperature ≤ 50°C to obtain a solid powder for later use ;

[0043] (2) The aqueous solution after step (1) gained distillation is filtered, and the hydrochloric acid aqueous solution decocting that filter residue adds concentration and is 0.05% v / v, and the mass ratio of hydrochloric acid water and filter residue is 6:1~8:1, and the time of decocting For 1 to 3 hours, filter, then combine the filtrates, concentrate to a relative density of 1.10 to 1.15 at 60°C, add ethanol to make the concentration of ethanol in the combined filt...

Embodiment 2

[0047] (1) Take 104g of honeysuckle, 415g of five-finger mandarin orange, 520g of Sanchaku, 310g of wild chrysanthemum, 310g of Nanlan root, and 835g of plum, add water to decoct, the mass ratio of the weight of water to the components weighed is 10:1, decoct Distilled for 1 to 2 hours, distilled, collected distilled liquid, added 50g of β-cyclodextrin to the distilled liquid, mixed to make it completely clathrated, filtered the mixed liquid, dried, and dried at a temperature of ≤50°C to obtain a solid powder for later use ;

[0048] (2) The aqueous solution after step (1) gained distillation is filtered, and the hydrochloric acid aqueous solution decocting that filter residue adds concentration and is 0.05% v / v, and the mass ratio of hydrochloric acid water and filter residue is 6:1~8:1, and the time of decocting For 1 to 3 hours, filter, then combine the filtrates, concentrate to a relative density of 1.10 to 1.15 at 60°C, add ethanol to make the concentration of ethanol in ...

Embodiment 3

[0052] (1) Take 110g of honeysuckle, 400g of mandarin mandarin orange, 540g of Sanchaku, 290g of wild chrysanthemum, 330g of Nanlan root, and 780g of plum, add water to decoct, the mass ratio of the weight of water to the components weighed is 10:1, decoct Distilled for 1 to 2 hours, distilled, collected distilled liquid, added 32g β-cyclodextrin to the distilled liquid, mixed to make it completely clathrated, filtered the mixed liquid, dried, and dried at a temperature ≤ 50°C to obtain a solid powder for later use ;

[0053] (2) The aqueous solution after step (1) gained distillation is filtered, and the hydrochloric acid aqueous solution decocting that filter residue adds concentration and is 0.05% v / v, and the mass ratio of hydrochloric acid water and filter residue is 6:1~8:1, and the time of decocting For 1 to 3 hours, filter, then combine the filtrates, concentrate to a relative density of 1.10 to 1.15 at 60°C, add ethanol to make the concentration of ethanol in the comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com