A kind of processing method of intermediate water activity preconditioning white fish

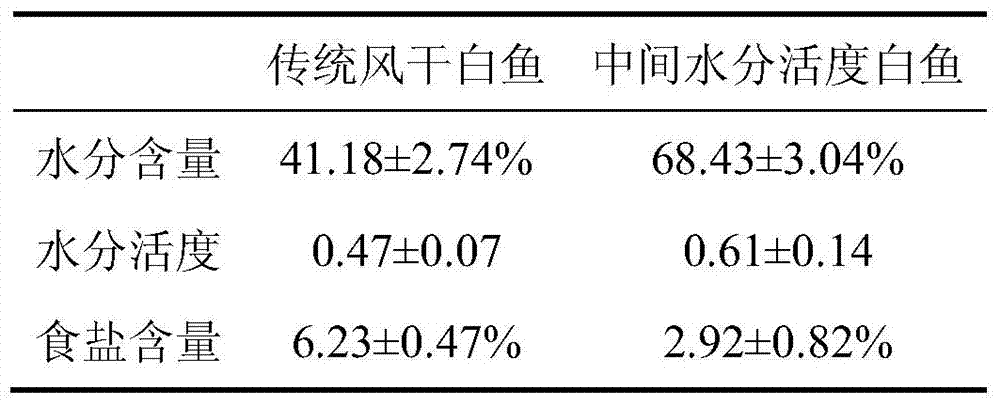

A processing method and a preconditioning technology, which are applied in the processing field of preconditioning whitefish with intermediate water activity to achieve the effects of preventing oxidative spoilage, simple operation, and improving taste and texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: the cultivation of lactic acid bacteria.

[0036] Lactic acid bacteria strain Lactobacillus delbrueckii subsp.bulgaricus L.B-FM-6 (preservation number: CGMCC NO.3049, the strain has been disclosed in 200910033694.8), stored in 20% glycerol at -20°C, in MRS culture medium with 2% inoculum Activated at 37°C for 48h, then transferred to MRS medium and cultured at 37°C for 48h.

[0037] MRS formula is: peptone 10.0g, yeast extract 5.0g, beef extract 10.0g, K 2 HPO 4 2.0g, MgSO 4 ·7H 2 O0.58g, MnSO 4 ﹒ 4H 2 O 0.25g, diammonium citrate 2.0g, sodium acetate 5.0g, glucose 20.0g, Tween 801.0mL, distilled water 1000mL, pH 6.8, sterilize at 121°C for 20min.

Embodiment 2

[0038] Example 2: Extraction and preparation of polysaccharides.

[0039] Take the lactic acid bacteria culture obtained in Example 1, centrifuge at 4000rpm at 4°C for 10min, add absolute ethanol to the supernatant to a final concentration of 75%, mix well and let stand at 4°C for 24h, centrifuge at 10000rpm at 4°C for 20min, collect the precipitate, and freeze Dried to obtain powdery polysaccharide, set aside.

[0040] The crude polysaccharide was purified by gel chromatography, and the molecular structure of the polysaccharide was identified. The results of infrared spectroscopy showed that the polysaccharide was at 2938cm -1 (O-H stretching vibration peak), 1658cm -1 (C=O, C=C asymmetric stretching vibration peak), 1405cm -1 (C-O, C=O symmetrical stretching vibration peak), 1138cm -1 (C-O-H, C-O-C vibration peaks of the sugar ring), 1061cm -1 (Ether bond C-O-C vibration absorption peak of pyranose ring), 977cm -1 (Deoxysugar absorption peak of rhamnose), 829cm -1(α-D ...

Embodiment 3

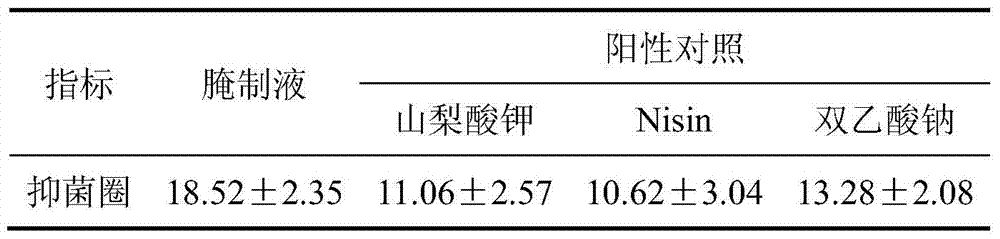

[0041] Embodiment 3: preparation of pickle solution.

[0042] Wash Houttuynia cordata, weigh 100g, add 200ml of water, and beat for 1min at low speed with a tissue homogenizer (Xibeile Electric Co., Ltd.). Houttuynia cordata homogenate is filtered with four layers of gauze, the homogenization cup is rinsed with a small amount of water, and the filtrates are combined. Weigh 200g of table salt, 500ml of cooking wine, and 14g of polysaccharides in step 2, mix them with Houttuynia cordata juice, add water to 5L, stir to dissolve, and set aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com