Rotor of rotating motor

A technology of rotating electrical machines and rotors, which is applied in the field of parallel rotating electrical machine rotors, can solve the problems of high manufacturing process and manufacturing cost, high manufacturing cost, high mechanical strength of rotor punching, and achieve the effect of reducing usage and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

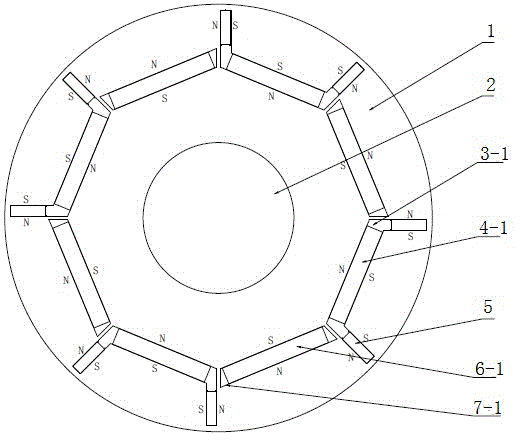

[0022] see figure 1 , the rotor of the rotating electrical machine of the present invention includes a rotating shaft 2 and a rotor core 1, a number of NdFeB magnets 5 are evenly and tangentially built in the rotor core 1, and iron is built radially between two adjacent NdFeB magnets 5. Ferrite magnets 4-1, 6-1; the adjacent NdFeB magnets 5 are arranged in N and N relative arrangements, and the adjacent ferrite magnets 4-1 and 6-1 are arranged with N and S intervals The way it is arranged.

[0023] In order to reasonably accommodate the magnets, a number of first-type slots 3-1 and second-type slots 7-1 are formed in the rotor core 1 and are evenly distributed and spaced apart. Among them, the first type of slot 3-1 includes a linear bottom slot and side slots, the second type of slot 7-1 is linear, and the NdFeB magnet 5 is placed in the side slot of the first type of slot 3-1 Inside, the ferrite magnets 4-1, 6-1 are placed in the bottom groove of the first type of slot 3-1...

Embodiment 2

[0026] see image 3 , the rotor structure of this embodiment is roughly the same as that of Embodiment 1, the difference mainly lies in that a third type of slot 3- 2, 7-2, ferrite magnets 4-2, 6-2 are built-in in the third type slot holes 3-2, 7-2, so that ferrite magnets 4-1, 4-2 , 6-1, 6-2 are double-layer structures. Such as Figure 4 As shown, the tangential NdFeB magnets 5 alone provide magnetic flux, and the radial ferrite magnets 4-1, 4-2, 6-1, 6-2 are connected in series to provide magnetic flux together. Specifically The magnetic flux goes as Figure 4 shown.

[0027] To sum up, in view of the fact that the tangential NdFeB permanent magnets and the radial ferrite permanent magnets provide magnetic flux in parallel, the magnetic potentials of the two need to be kept consistent. In the actual application process, the residual magnetic induction of NdFeB magnet 5 B r is generally around 1.2T, the coercive force is around 907kA / m, and the residual magnetic inducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com