Narrow-band spiral thin-layer chromatography plate and preparation method thereof

A technology of thin-layer chromatography plate and chromatographic plate, which is applied in the field of narrow-band spiral thin-layer chromatography plate and its preparation, can solve problems such as difficulties, increased qualitative and quantitative analysis of samples, and increased value differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

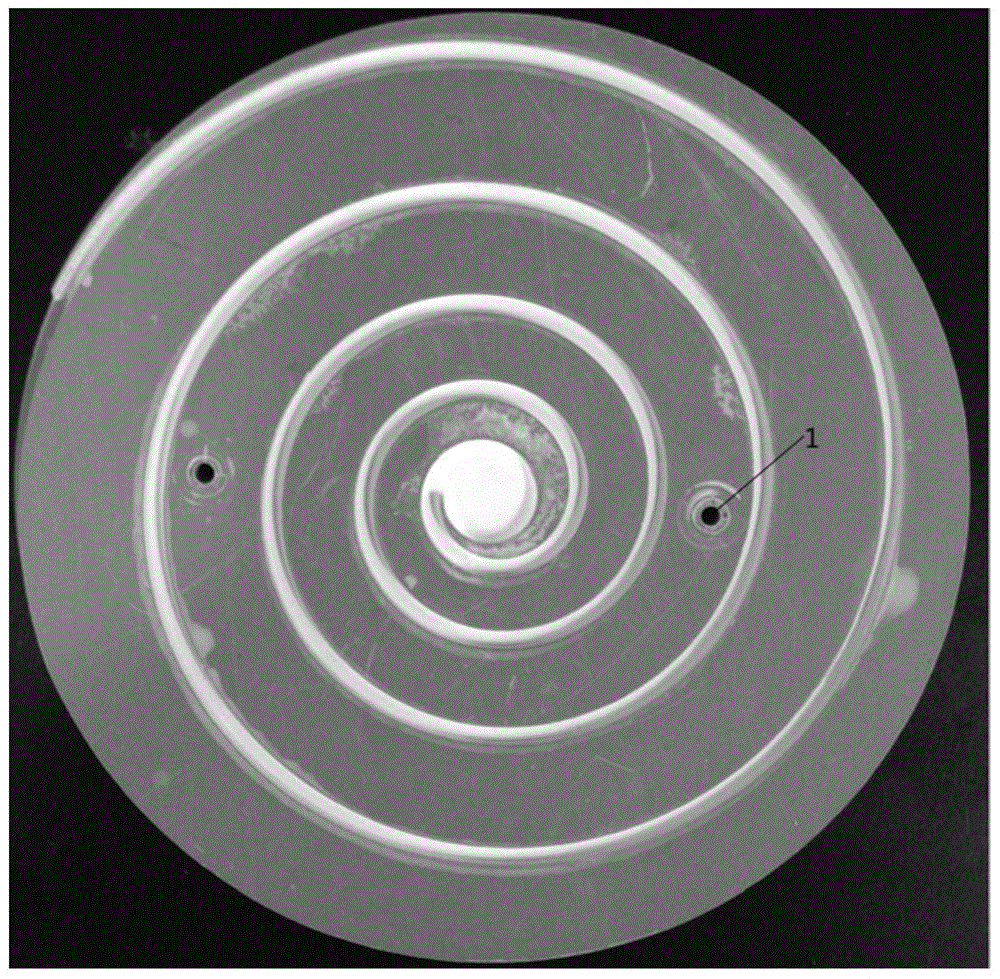

[0073] (1) On the circular thin-layer plate of polyvinyl chloride, the f(θ) extending to the edge is set as a linear function (Archimedes spiral, f(θ)=2θ) starting from the center of the circle. groove, the width of the groove is 3mm, and the depth is about 2mm;

[0074] (2) 0.7g of barium fluoride nanoparticles is added into a mortar and thoroughly ground to obtain a particle diameter of barium fluoride nanoparticles of about 95nm;

[0075] (3) Add 10 mL of ethanol to the powder obtained in step 2, transfer it to a 30×60 weighing bottle, and ultrasonicate for 20 minutes to form a suspension. After standing for 2 minutes,

[0076] (4) Absorb step 3 to obtain the upper layer suspension, start from the beginning of the groove, evenly spread in the groove of the PVC thin-layer plate, make the surface of the stationary phase even and even, place it in a horizontal position, wait for the ethanol to volatilize, fix The phase is whitish and nearly dry, and a narrow-band spiral thin-...

Embodiment 2

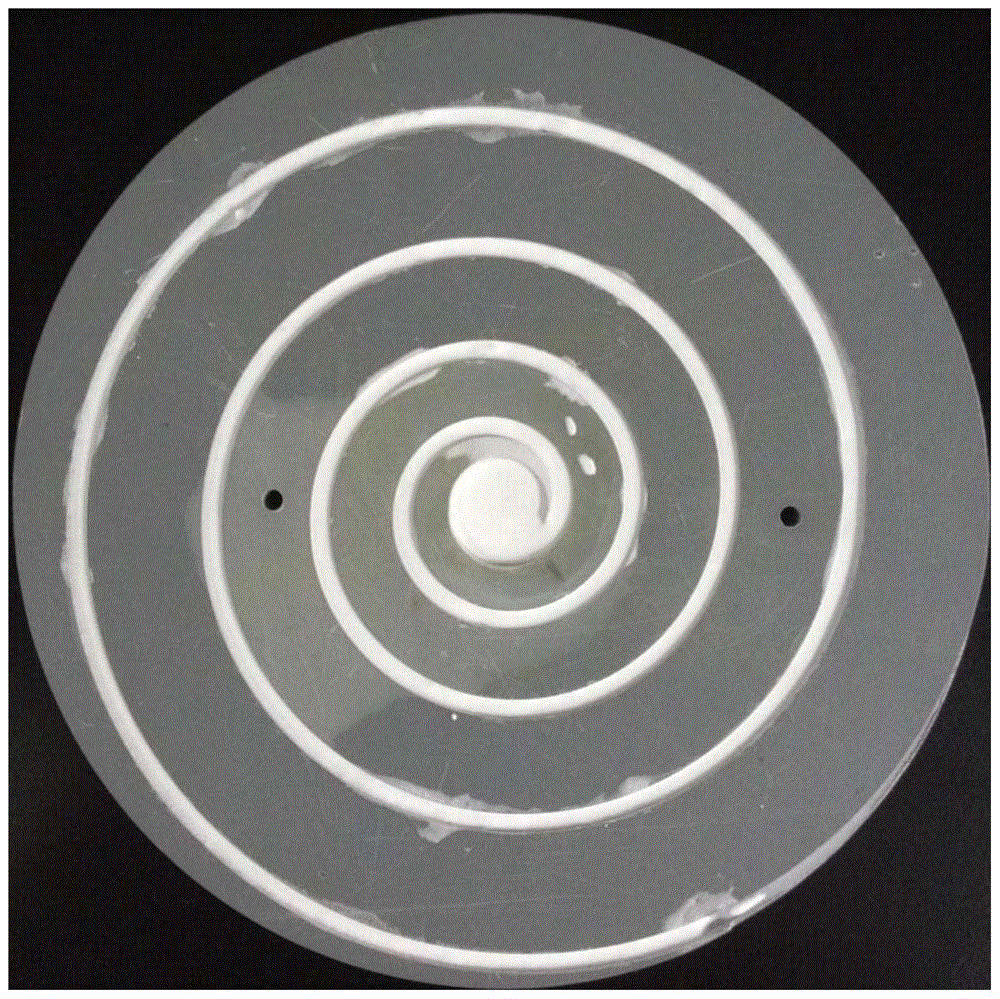

[0078] (1) On the circular thin-layer plate of polyvinyl chloride, the f(θ) extending to the edge is set as a linear function (Archimedes spiral, f(θ)=2θ) starting from the center of the circle. groove, the width of the groove is 3mm, and the depth is about 2mm;

[0079] (2) Take 10g of silica gel G (400 mesh) and place it in a beaker;

[0080] (3) Add 50g of water to the beaker filled with silica gel G, mix evenly, and let it stand for a while until no bubbles emerge from the suspension;

[0081] (4) Draw the mixed suspension, start from the beginning of the groove, and evenly spread it in the groove provided on the polyvinyl chloride chromatographic plate to make the surface of the stationary phase even and even, place it in a horizontal position, and wait for the water to volatilize. The stationary phase is whitish and nearly dry, and a narrow-band spiral thin-layer chromatographic plate with a smooth surface is obtained, such as figure 2 shown.

Embodiment 3

[0083] (1) On the circular thin-layer plate of polyvinyl chloride, the f(θ) extending to the edge is opened as the starting point with its center of circle as the exponential function (logarithmic spiral, f(θ)=e 0.2θ ) with a groove width of 3 mm and a depth of approximately 2 mm;

[0084] (2) Take 10g of silica gel G (40μm) and place it in a beaker;

[0085] (3) Add about 50g of water to the beaker filled with silica gel G, mix well, and let it stand for a while until no bubbles emerge from the suspension;

[0086] (4) Draw the mixed suspension, start from the beginning of the groove, and evenly spread it in the groove provided on the polyvinyl chloride chromatographic plate to make the surface of the stationary phase even and even, place it in a horizontal position, and wait for the water to volatilize. The stationary phase is whitish and nearly dry, and a narrow-band spiral thin-layer chromatographic plate with a smooth surface is obtained, such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com