Ultrasonic phosphating solution for carbon steel, preparation method thereof and method for phosphating carbon steel by adopting phosphating solution

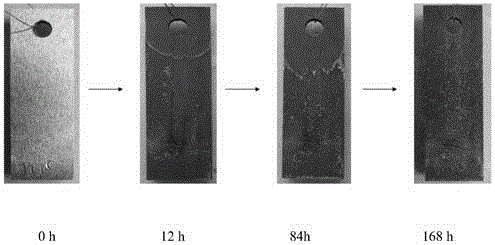

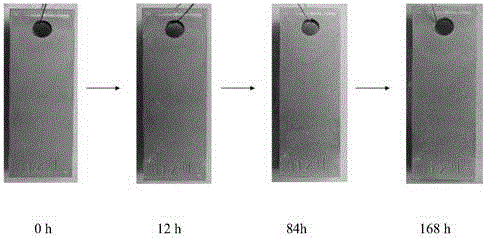

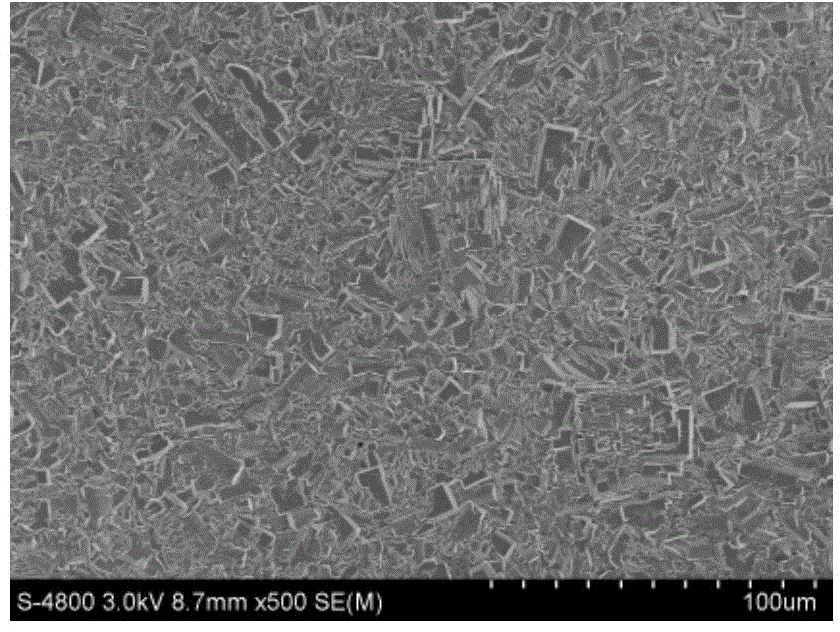

A technology of phosphating liquid and carbon steel, applied in the field of phosphating, to achieve the effect of dense phosphating film, fine particles and small surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A preparation method of a carbon steel ultrasonic phosphating solution of the present invention comprises the following steps:

[0036] (1) Dissolve ZnO with water to make a paste, then add 85% of H 3 PO 4 Add, stir and age for more than 24h;

[0037] (2) adding 50% of Mn(NO) in the solution obtained in step (1) successively 3 ) 2 , NaNO 3 , hydroxylamine sulfate, stir evenly, add distilled water to constant volume to obtain a phosphating solution; the proportion of each component in the described phosphating solution in parts by weight is:

[0038] ZnO: 5-20g / L, 85% H in mass percentage 3 PO 4 : 50-80g / L, hydroxylamine sulfate: 2-14g / L, NaNO 3 : 20-50g / L, 50% Mn (NO 3 ) 2 : 2-12g / L;

[0039] (3) Add NaOH solution dropwise to the phosphating solution to adjust the pH of the phosphating solution to 2-3.

[0040] The pH of the phosphating solution of the present invention is preferably 2.4-2.8. PH value is an important parameter of phosphating process. The siz...

Embodiment 1

[0053] (1) Dissolve ZnO with water to make a paste, then add 85% of H 3 PO 4 Add, stir and age for more than 24h;

[0054] (2) adding 50% of Mn(NO) in the solution obtained in step (1) successively 3 ) 2 , NaNO 3 , hydroxylamine sulfate (HAS), stir evenly, add distilled water to make the phosphating solution;

[0055] (3) Add NaOH solution dropwise to the phosphating solution to adjust the pH of the phosphating solution.

[0056] The phosphating solution obtained by this method, the parts by weight of each component in parts by weight are:

[0057] ZnO: 18g / L, 85%H 3 PO 4 : 80g / L, hydroxylamine sulfate (HAS): 12g / L, NaNO 3 : 25g / L, 50﹪Mn(NO3) 2 : 4g / L. Phosphating solution pH value: 2.4-2.8, free acidity: 5.2 points, total acidity: 98 points.

[0058] Using this phosphating solution to phosphate carbon steel, the specific steps are:

[0059] (1) The carbon steel substrate sample is cleaned and pretreated; the steps of cleaning and pretreatment are: (a) NaOH is 4g / L...

Embodiment 2

[0064] The phosphating solution was prepared in the same manner as in Example 1,

[0065] The obtained phosphating solution in terms of parts by weight of each component in parts by weight is:

[0066] ZnO: 9g / L, 85%H 3 PO 4 : 70g / L, hydroxylamine sulfate (HAS): 14g / L, NaNO 3 : 40g / L, 50﹪Mn(NO3) 2 : 8g / L. In this embodiment, the pH value of the phosphating solution is 2.4-2.8, the free acidity is 4.7 points, and the total acidity is 90 points.

[0067] The phosphating process is: the steps of the cleaning pretreatment of the present embodiment are: (a) 10g / L and Na in NaOH 2 SiO 3 The carbon steel substrate was ultrasonically cleaned in a solution of 2 g / L for 5 minutes to remove part of the grease on the surface of the substrate; (b) the carbon steel substrate was immersed in an ethanol solution with a mass percentage of 95% for ultrasonic cleaning for 3 minutes: (c) ultrasonic cleaning in distilled water Carbon steel substrate for 4 min; (d) drying at room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Free acidity | aaaaa | aaaaa |

| Total acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com