Double-layer titanium aluminum/aluminum silicon composite material as well as preparation method and application thereof

A composite material, titanium-aluminum alloy technology, applied in the direction of semiconductor/solid-state device parts, electrical components, circuits, etc., can solve the problems of physical and mechanical properties mismatch, mechanical properties and sealing performance deterioration, composite interface problems and other problems , to give full play to the advantages of comprehensive performance, excellent interface matching, and good interface integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

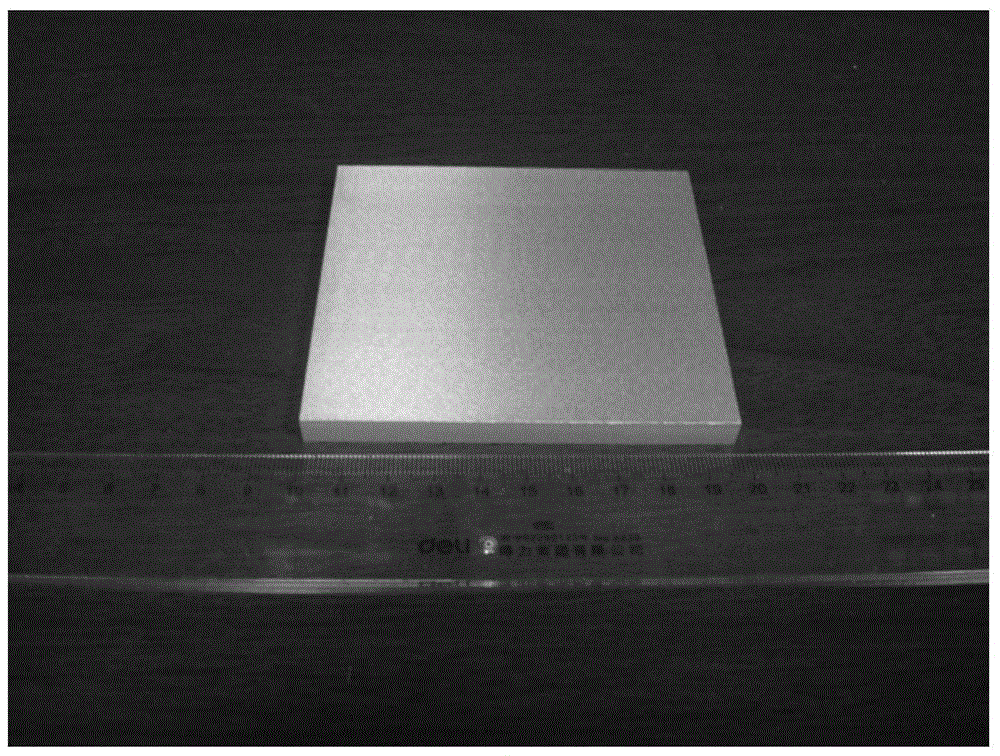

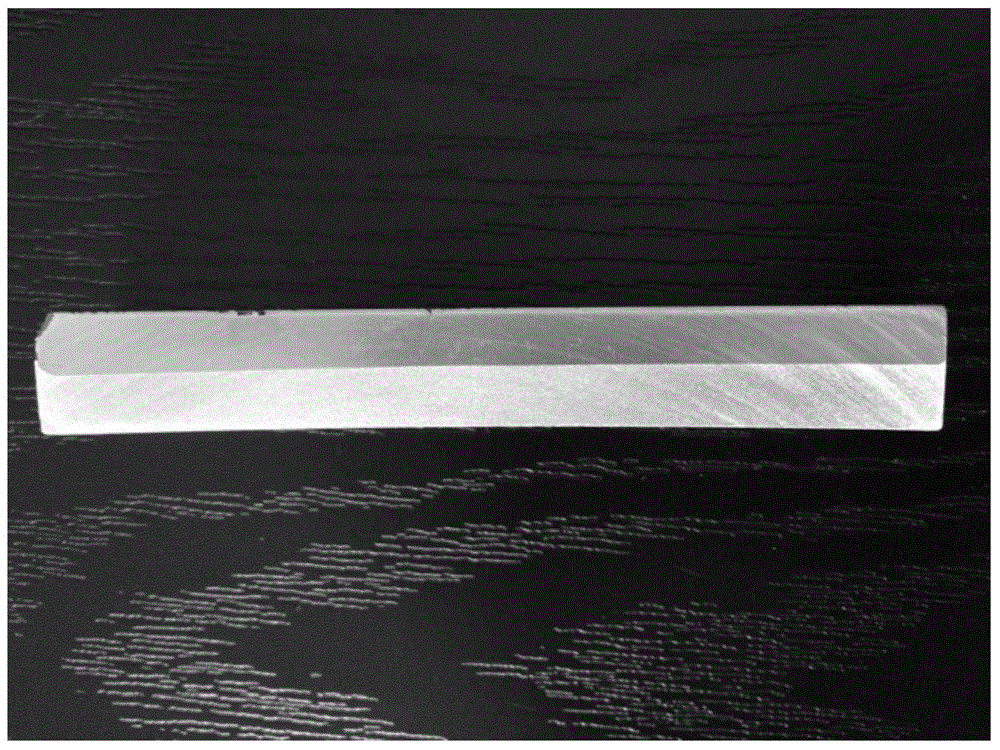

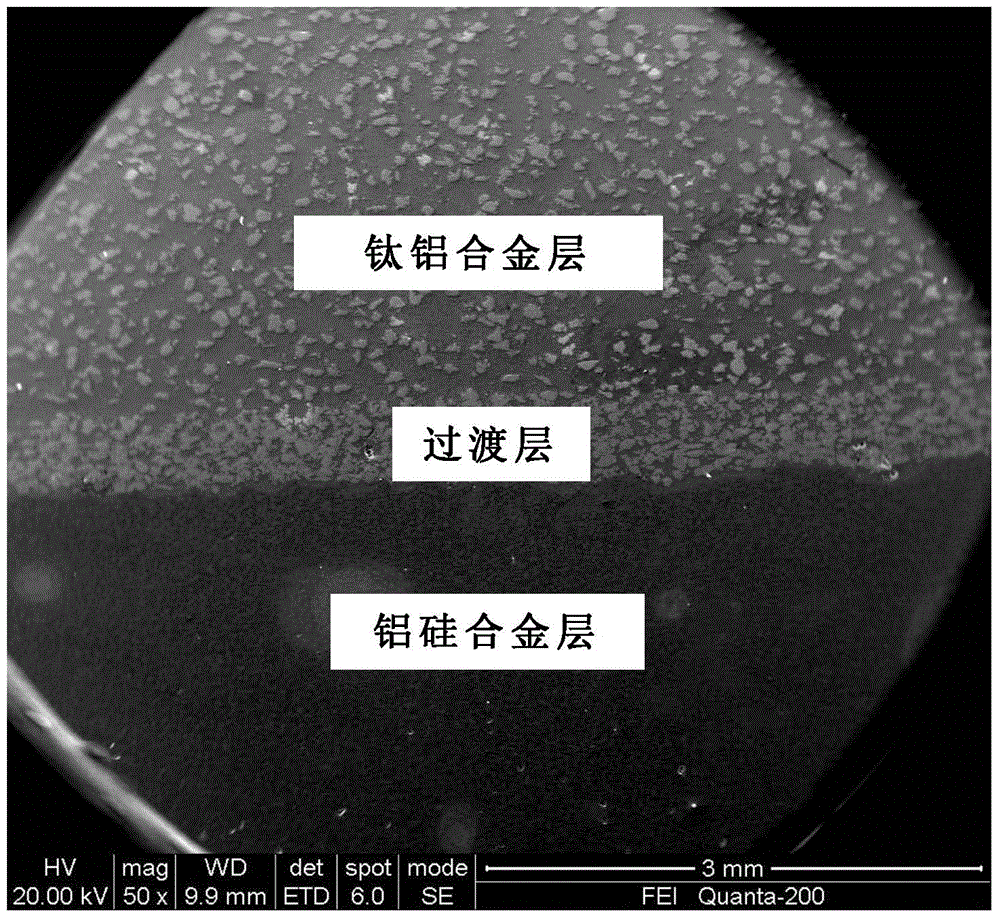

[0067] A double-layer titanium-aluminum / aluminum-silicon composite electronic packaging material is prepared by a sintering method, wherein the composition range of the titanium-aluminum alloy is 95% of Ti and 5% of Al. The composition range of the aluminum-silicon alloy is that Si is 70% (mass fraction), and Al is the balance. The average particle size of the aluminum powder is 5 μm, the average particle size of the titanium powder is 20 μm, and the average particle size of the silicon powder is 20 μm. The above-mentioned titanium powder, silicon powder and aluminum powder are respectively weighed on an electronic balance, and proportioned according to their respective mass percentages to obtain titanium-aluminum mixed powder and aluminum-silicon mixed powder with corresponding components. The mixed powder was mixed and ball milled on a three-dimensional mixer, the ball milling time was 60 minutes, and the mixing rotation speed was controlled at 30 times / min. The mixed powde...

Embodiment 2

[0075] A double-layer titanium-aluminum / aluminum-silicon composite electronic packaging material is prepared by a sintering method, wherein the applied titanium-aluminum alloy composition range is 50% of Ti content and 50% of Al content. The composition range of the aluminum-silicon alloy used is 10% (mass fraction) of Si and the balance of aluminum. The average particle size of the aluminum powder is 20 μm, the average particle size of the titanium powder is 70 μm, and the average particle size of the silicon powder is 70 μm. The above-mentioned powders are weighed on an electronic balance, and proportioned according to their respective mass percentages to obtain titanium-aluminum mixed powder and aluminum-silicon mixed powder with corresponding components. The mixed powder is mixed and ball milled on a three-dimensional mixer, the mixing and ball milling time is controlled at 90 minutes, and the mixing rotation speed is controlled at 60 times / min. The mixed powder mixed by ...

Embodiment 3

[0081] A double-layer titanium-aluminum / aluminum-silicon composite electronic packaging material is prepared by a sintering method, wherein the composition range of the applied titanium-aluminum alloy is 70% of Ti and 30% of Al. The composition range of the aluminum-silicon alloy used is 50% (mass fraction) of Si and the balance of aluminum. The average particle size of the aluminum powder is 10 μm, the average particle size of the titanium powder is 50 μm, and the average particle size of the silicon powder is 50 μm. The titanium powder, the silicon powder, and the aluminum powder are weighed on an electronic balance respectively, and proportioned according to their respective mass percentages to obtain titanium-aluminum mixed powder and aluminum-silicon mixed powder with corresponding components. The mixed powder is mixed and ball milled on a three-dimensional mixer. The ball milling time is controlled at 75 minutes according to the volume of the powder, and the mixing rotat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com