A kind of method that contains ni-co catalyst to catalyze deep desulfurization of gasoline

A deep desulfurization and catalytic gasoline technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of unqualified mercaptan sulfur, unable to meet technical requirements, and unseen problems, so as to reduce the severity of the reaction , Octane number loss optimization, hydrogen consumption optimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

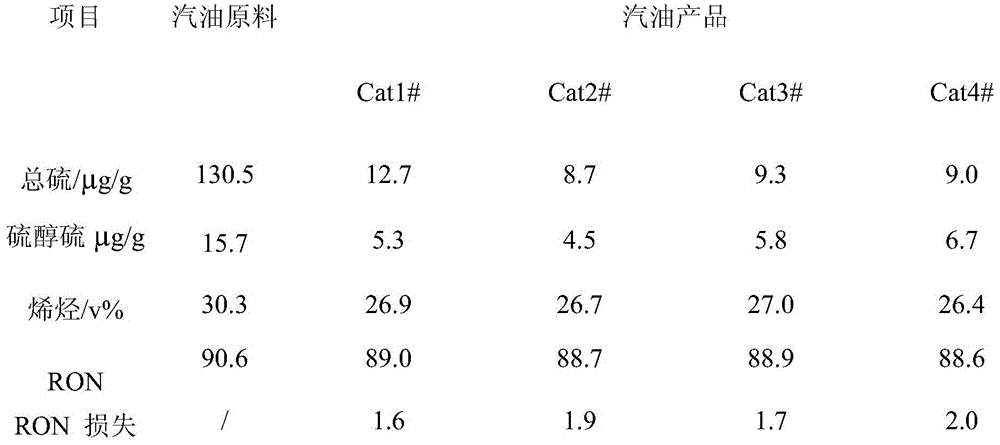

Embodiment 1

[0032] Weigh 100 g of pseudo-boehmite, add 2.5 g of sesame powder, and then add 3% nitric acid aqueous solution, knead and extrude, dry at 120°C for 4 hours, and then calcinate at 650°C for 4 hours to prepare a catalyst carrier. Test the water absorption of the carrier according to the conventional method, and then configure the active component impregnation solution according to the water absorption of the carrier according to the equal volume dipping method. First, weigh out 45ml of ammonia, then add 2g of cobalt nitrate and 60g of nickel nitrate in sequence until it dissolves, and finally make the volume constant with ammonia. The carrier was impregnated with an equal volume impregnation method to make the catalyst carrier fully absorb the active component impregnation solution, and then placed for 12 hours, the catalyst was dried at 120°C for 4 hours, and calcined at 500°C for 4 hours to prepare a catalyst sample Cat-1#.

Embodiment 2

[0034] According to the carrier preparation method in Example 1, 100 g of the catalyst carrier was prepared, and then the active component impregnation solution was configured. The preparation method was the same as in Example 1. First, weigh out 50ml of ammonia, then add 5g of cobalt nitrate and 42g of nickel acetate and stir to dissolve, and finally make the volume constant with ammonia. The metal active component impregnation method, drying and calcination conditions were the same as in Example 1, and the catalyst sample Cat-2# was prepared.

Embodiment 3

[0036] According to the carrier preparation method in Example 1, 100 g of the catalyst carrier was prepared, and then the active component impregnation solution was configured. The preparation method was the same as in Example 1. First weigh 50ml of ammonia, then add 8g of cobalt nitrate and 30g of nickel acetate and stir to dissolve, and finally make the volume constant with ammonia. The metal active component impregnation method, drying and calcination conditions were the same as in Example 1, and the catalyst sample Cat-3# was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com