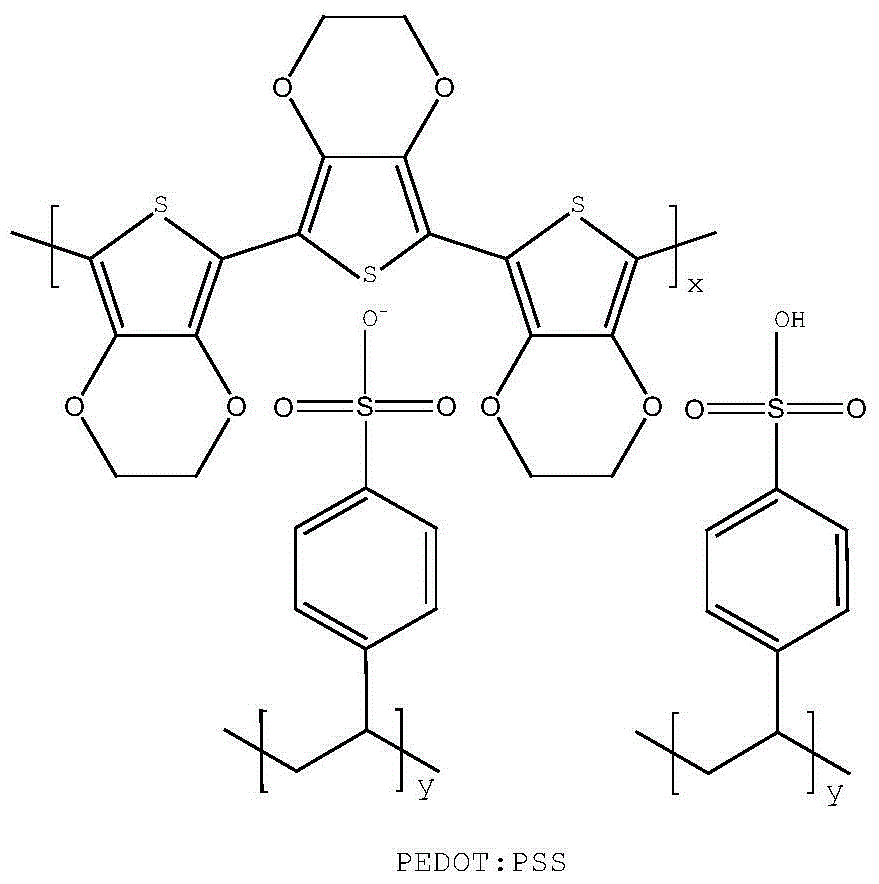

Method for preparing high-conductivity PEDOT-PSS (poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonate)) solution

A PEDOT-PSS, high conductivity technology, applied in the field of preparation of high conductivity PEDOT-PSS solution, can solve the problems of large particle diameter, poor uniformity, poor performance stability, etc., to improve particle size uniformity , Improve performance stability, improve conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

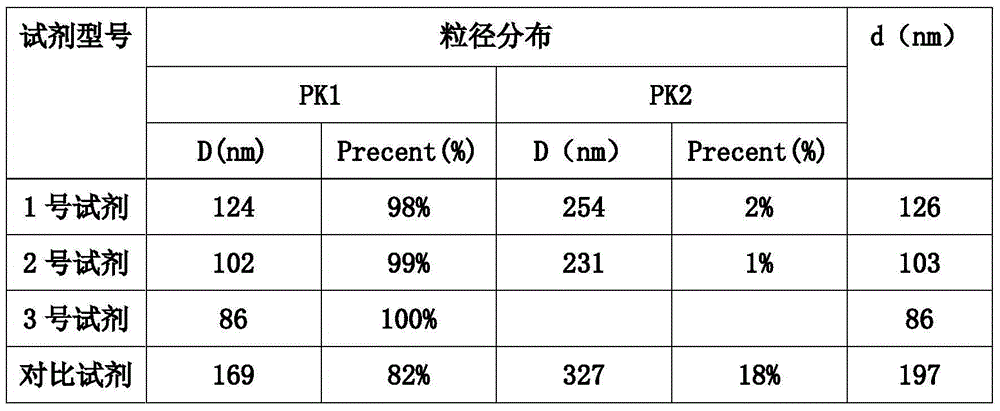

Embodiment 1

[0020] Embodiment 1: the method for preparing PEDOT-PSS solution, this method specifically comprises the following steps:

[0021] a. Add 35g of sodium polystyrene sulfonate to 3500ml of deionized aqueous solution to dissolve, and keep the temperature of the solution at 7°C to obtain product A;

[0022] b. Add 20 ml of a solution containing 2.5 grams of sulfuric acid to product A, then add 10.5 g of 3,4-ethylenedioxythiophene to react, and use high-purity nitrogen to deoxygenate during the reaction to obtain product B;

[0023] c. Add 0.002g of Fe 2 (SO 4 ) 3 solution and 25.5g(Na) 2 S 2 o 8 The solutions are mixed, the mixed solution is placed in a constant pressure separatory funnel, and is added dropwise to product B at a rate of one drop per 1 second (the capacity of the droplet of a conventional constant pressure separatory funnel is common knowledge in the art), Stir simultaneously with the rotating speed of 350r / min, the stirring time is 40 hours, obtains C produc...

Embodiment 2

[0025] Embodiment 2: the method for preparing PEDOT-PSS solution, this method specifically comprises the following steps:

[0026] a. Add 45.5 g of sodium polystyrene sulfonate to 3800 ml of deionized aqueous solution to dissolve, and keep the temperature of the solution at 15°C to obtain product A;

[0027] b. Add 35ml of a solution containing 4 grams of sulfuric acid to product A, then add 16g of 3,4-ethylenedioxythiophene to react, and use high-purity nitrogen to deoxygenate during the reaction to obtain product B;

[0028] c. Add 0.005g of Fe 2 (SO 4 ) 3 solution and 35g(Na) 2 S 2 o 8 Mix the solutions, place the mixed solution in a constant pressure separatory funnel, add dropwise to product B at a rate of one drop every 4 seconds, and stir at a speed of 650 r / min at the same time, and the stirring time is 55 hours to obtain product C;

[0029] d. Put 50g of dimethyl sulfoxide, 18g of ethylene glycol and 24g of ethanol into product C for reaction, and stir at a spee...

Embodiment 3

[0030] Embodiment 3: the method for preparing PEDOT-PSS solution, this method specifically comprises the following steps:

[0031] a. Add 41.48g of sodium polystyrene sulfonate to 3200ml of deionized aqueous solution to dissolve, and keep the solution temperature at 10°C to obtain product A;

[0032] b. Add 30 ml of a solution containing 3.72 grams of sulfuric acid to product A, then add 10.15 g of 3,4-ethylenedioxythiophene to react, and use high-purity nitrogen to remove oxygen during the reaction to obtain product B;

[0033] c. Add 0.0013g of Fe 2 (SO 4 ) 3 solution and 27.45g(Na) 2 S 2 o 8 Mix the solutions, place the mixed solution in a constant pressure separatory funnel, add dropwise to product B at a rate of one drop every 2 seconds, and stir at a speed of 400 r / min at the same time, and the stirring time is 24 hours to obtain product C;

[0034] d. Put 50g of dimethyl sulfoxide, 18g of ethylene glycol and 24g of ethanol into product C for reaction, and stir at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com