Preparation and application of porous ZSM-5 zeolite molecular sieve aggregate

A ZSM-5, multi-level pore technology, applied in chemical catalytic materials and chemical application fields, can solve the problems of affecting the conversion rate of chemical synthesis and low time consumption, restriction of reaction molecular diffusion, large amount of template agent, etc., to achieve industrial promotion and application Promising, high conversion and selectivity, effects of a process that reduces secondary roasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

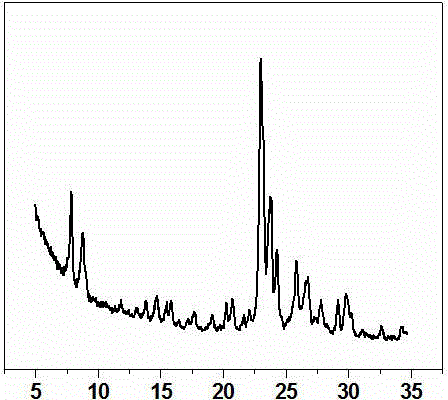

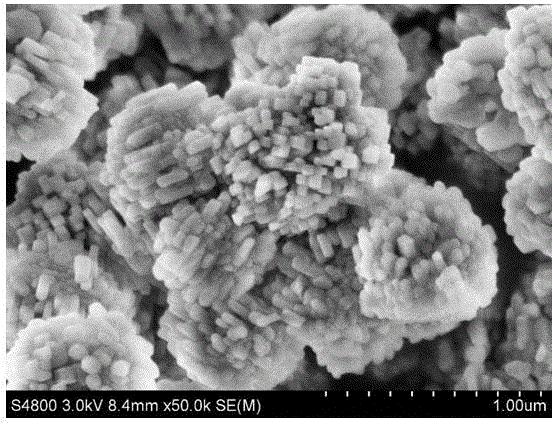

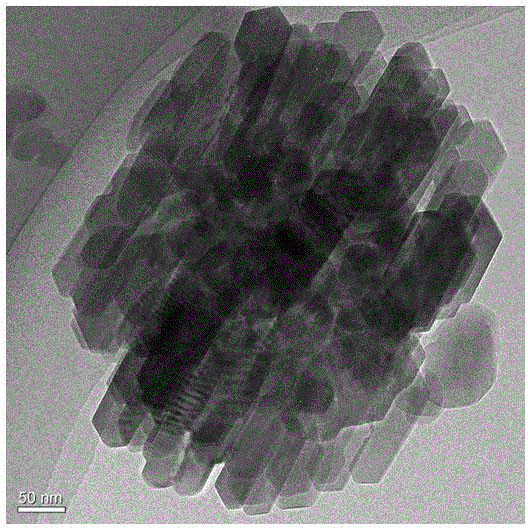

Image

Examples

Embodiment 1

[0021] a. Preparation of silica-alumina sol-gel

[0022] will contain 0.033mol Al 2 o 3 A solution of aluminum sulfate was added dropwise to a solution containing 1mol SiO 2 In the sodium silicate solution, add hydrochloric acid to adjust the pH value to 7 under stirring, filter after stirring for 30 minutes, and transfer the filter cake to the autoclave to replenish water to H 2 O / SiO 2 With a molar ratio of 25, polyhydroxylated silica-alumina sol-gels were prepared.

[0023] b. Preparation of seed directing agent

[0024] tetrapropylammonium hydroxide (TPAOH) with tetraethyl orthosilicate (TEOS) and H 2 O was mixed at a molar ratio of 0.35:1:20, stirred into a clear solution, and crystallized at 100°C for 24 hours to obtain a tetrapropylammonium seed directing agent.

[0025] c. Preparation of H-zeolite aggregates

[0026] Add the above-prepared tetrapropylammonium seed directing agent to the polyhydroxylated silicon-aluminum sol-gel at a molar ratio of 0.015 to the S...

Embodiment 2

[0031] Take 0.15 g of the hierarchically porous H-ZSM-5 zeolite molecular sieve aggregate prepared in Example 1 as a catalyst and add it to 7 g of cyclohexane with 0.7 g of tert-butanol and 0.5 g of phenol in a three-necked flask equipped with a reflux condenser, The hydroxylation reaction was carried out at 100 °C for 4 hours. After the reaction, the catalyst was filtered out by centrifugation. The conversion rate of phenol of the product was determined by gas chromatography to be 33%, and the selectivity was 98%.

Embodiment 3

[0033] a. Preparation of silica-alumina sol-gel

[0034] will contain 0.017mol Al 2 o 3 A solution of aluminum sulfate was added dropwise to a solution containing 1mol SiO 2 Add hydrochloric acid to adjust the pH value to 8 under stirring, filter after stirring for 30 minutes, and transfer the filter cake to the autoclave to replenish water to H 2 O / SiO 2 With a molar ratio of 25, polyhydroxylated silica-alumina sol-gels were prepared.

[0035] b. Preparation of seed directing agent

[0036] tetrapropylammonium bromide (TPABr) with tetraethyl orthosilicate (TEOS) and H 2 O was mixed at a molar ratio of 0.2:1:20, stirred into a clear solution, and crystallized at 100°C for 24 hours to obtain a tetrapropylammonium seed directing agent.

[0037] c. Preparation of H-zeolite aggregates

[0038] Add the above-prepared tetrapropylammonium seed directing agent to the polyhydroxylated silicon-aluminum sol-gel at a molar ratio of 0.015 to the Si of the synthesis system, stir and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com