Special sling for hoisting extra-large structural modules for nuclear power plants

A technology for structural modules and nuclear power plants, which is applied in the directions of transportation, packaging, and load hoisting components. It can solve the problems of complex connection between fixed pulley and movable pulley system, long slings, and easy connection deviation, so as to improve the effective dispatching capacity and improve the reliability of the equipment. Uniform force and safe lifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

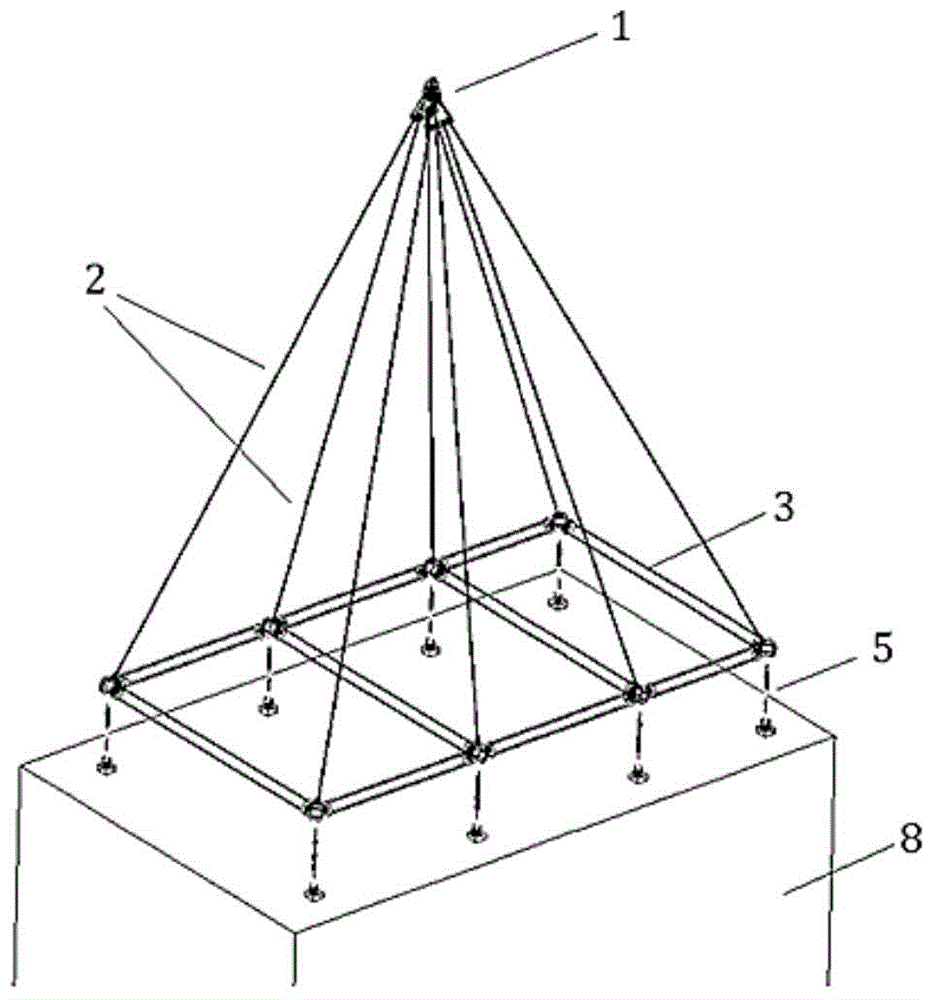

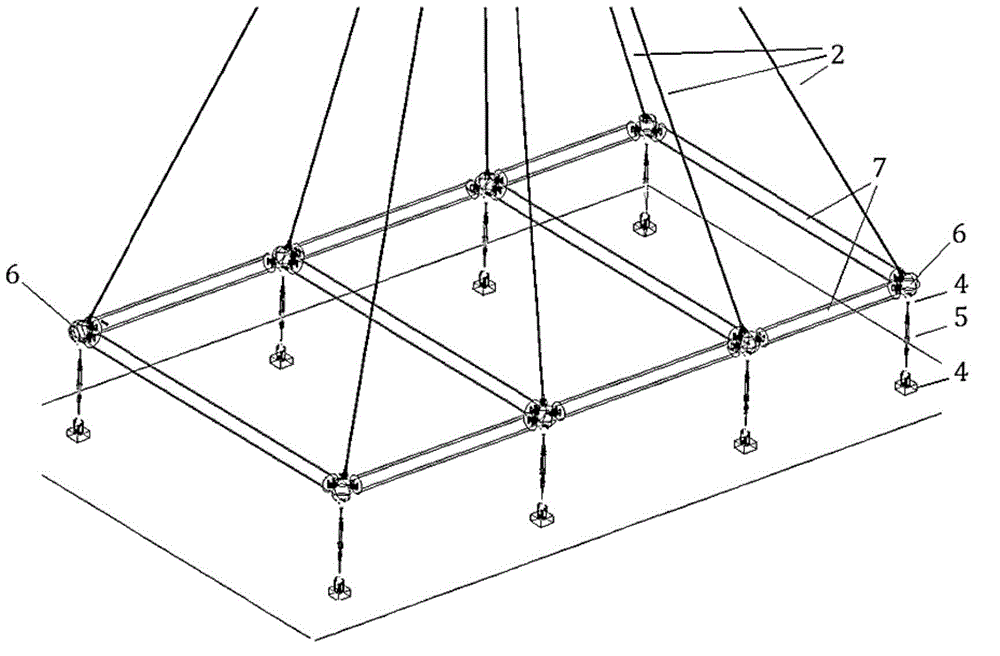

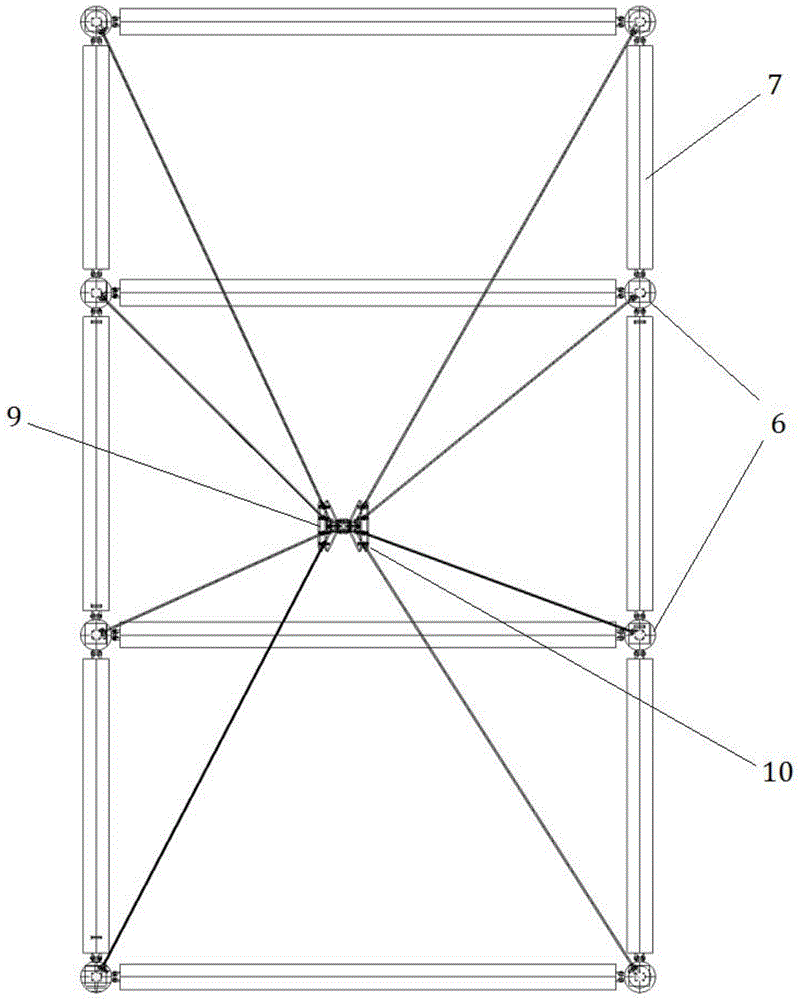

[0027] Such as figure 1 with figure 2 As shown, this embodiment includes: distributor 1, several steel pipe beams 7 and several spherical nodes 6, wherein: steel pipe beams 7 are connected in pairs through spherical nodes 6 to form balance beam frames 3, and balance beam frames 3 are respectively connected to distributor 1 It is connected with the hoisting module 8.

[0028] The distributor 1 and the balance beam frame 3 are connected through an upper sling 2 .

[0029] Such as Figure 5 As shown, the bottom of the dispenser 1 is provided with two lugs 9 , and each lug 9 is provided with four buckles 10 for correspondingly connecting the upper slings 2 .

[0030] The balance beam frame 3 and the hoisting module 8 are connected to each other through a hydraulic cylinder sling 5, one end of the hydraulic cylinder sling 5 is rotationally connected to the lower ear plate 11 of each spherical node 6, and the other end is connected to the hoisting module 8 Rotate the connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com